Plastics for space - problem solvers on Earth

Just as stone, iron and bronze shaped our early history, manmade plastics material today shape our lives in an ever more permanent way. In their 100-year history plastics have fundamentally changed our world. Today they are integrated components of modern civilisation, offering immense potential for innovation.

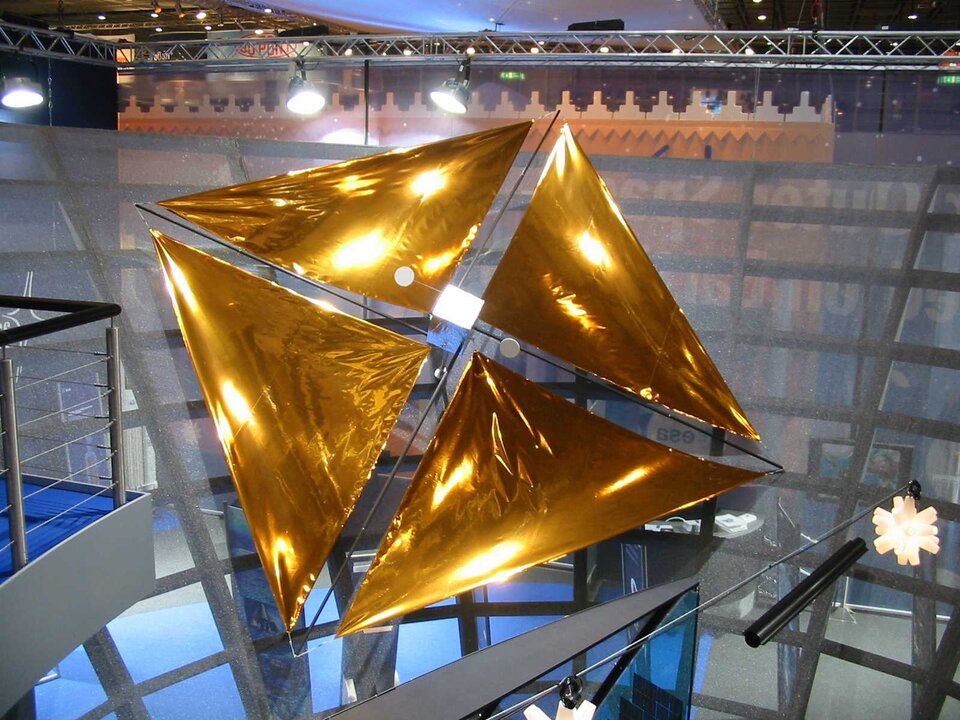

K2001, the world's biggest trade fair for plastics and rubber, hosted last week in Dusseldorf a special presentation "Plastics in outer space - solutions for the Earth". The stand was a joint initiative of ESA, VKE (Association of the Plastics Producing Industry) and APME (Association of Plastics Manufacturers in Europe) and was a magnet for the some 230.000 trade visitors.

A crowd-puller

"We have registered considerable interest in our spin-offs from plastics developed for space and used on Earth. It is widely recognised that space creates innovative materials including new types of plastic with great potential on Earth", says Hans Dworak from ESA's Technology Transfer Programme.

Although there were more than 2800 exhibitors, the ESA-VKE-APME joint stand attracted quite a crowd. "In particular we have had many requests from smaller companies searching for specific technologies which could improve an existing product or resolve a specific technical problem."

Plastics play a key role in space - new plastics materials are constantly being researched to survive the harsh environment of space. Just think about the outdoor temperature of the International Space Station - minus 157 degrees C to plus 177 degrees C! For humans to survive in this environment requires very special suits that use innovative plastic materials.

Spacecraft also need to be "dressed" to resist similar heat and cold variations, vacuum radiation, and electrical storms. They defy these extreme conditions in space thanks to shields and insulation materials made out of plastics.

Technology transfer from space to Earth

Many materials developed for European space programmes have now found their way into terrestrial applications thanks to ESA's Technology Transfer Programme, frequently resolving problems in our life here on Earth in new and innovative ways.

Just some of the examples presented at K2001:

- Astronaut suit technology used for protective clothing for fighter pilots, fire fighters, chemical spillage cleanup teams, emergency services, motorcyclists and divers.

- Wafer-thin, thermal insulation film developed to protect spacecraft is now being used for high-performance insulation on Earth, for example in the tomograph with its vacuum chamber being cooled at minus 270 degree C.

- Films developed to record every impact from microscopic dust particles and micrometeoroids on spacecraft can be used in early detection of car accidents.

- Materials and systems developed for vibration damping in the space station can be used to reduce vibrations in trains resulting in higher speed and improved comfort.

- Carbon fibre developed for satellites is now used in aircraft and Formula-1 racing cars.

Industrial robots are produced in the same carbon fibre composite material resulting in 80% weight reduction and twice the operational speed with even higher precision.

The ESA Portal will over the coming month feature stories on these successful technology transfers.

Also on display were ESA's SpaceHouse and a full-size copy of the Dutch solar-powered car Nuna.

ESA has developed the concept of a self-sufficient SpaceHouse that could make it possible for astronauts to stay for a longer period on other planets. It is based upon carbon fiber and epoxy resin composites, specially designed to protect against small meteorite showers.

The Nuna solar car is taking part in the 3010 kilometre solar-race through Australia starting 18 November. Plastics and space technology have played a major role in constructing one of the most efficient solar vehicles ever built. High performance solar cells push the car up to 160 km/h.

International Space Station commercialisation

The International Space Station was also a hot topic, in particular its commercialisation activities and synergies with the plastics industry. Several members of APME have expressed their interest to investigate with ESA the opportunity to promote and broaden the research conducted on-board the Station.

Innovative materials from space requested by European industry

ESA's technology transfer programme has been operating for over ten years and plastics play an important role. Numerous polymer applications originally created for specific requirements in space, have now found their way into our daily life.

"Innovative materials such as plastics have often provided the solution to the problems and challenges encountered in space missions. Now the same technologies are helping to meet the challenges we face on Earth", says Pierre Brisson, Head of ESA's Technology Transfer Programme.

"K2001 confirmed for us European industry's strong interest in using advanced new materials researched and developed for space. The flow of innovation from space to solutions on Earth will intensify, continuing to improve our daily life."

For more information, see the special web site for ESA's Technology Transfer Programme.