MetOp-B is ESA test centre’s latest task of busy year

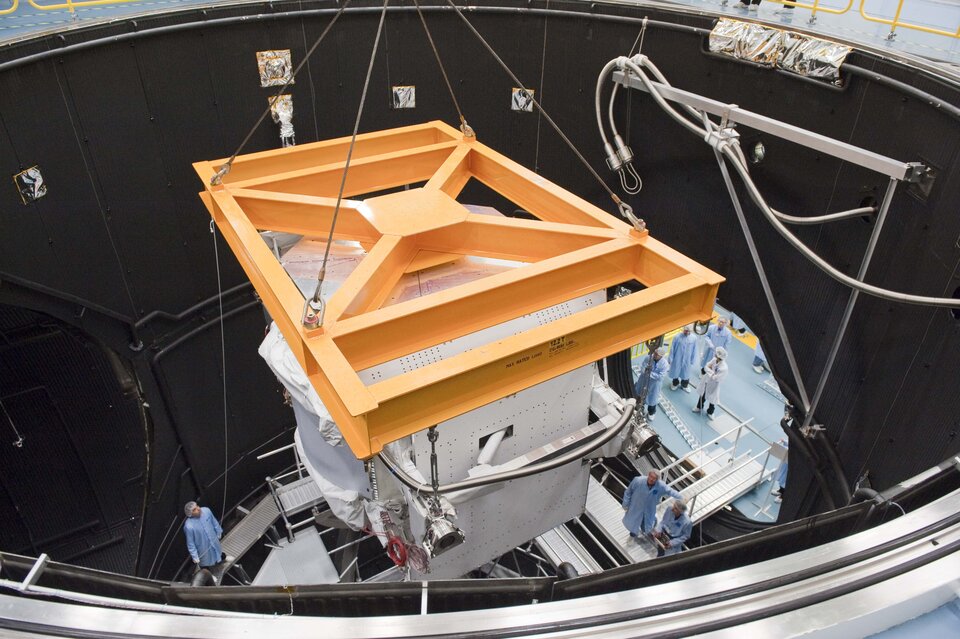

The Payload Module of the giant MetOp-B weather satellite has been lowered into ESA’s largest vacuum chamber. ESTEC Test Centre engineers will be subjecting it to prolonged space conditions – their latest assignment in a busy year.

“2010 is turning out to be an extremely demanding year for the Test Centre,” said Gaetan Piret, head of the centre. “From January to December we don’t have a single day free in our Large Space Simulator.”

The largest European spacecraft pass through this unique Netherlands site on their way to space. The ESTEC Test Centre offers a multitude of testing facilities enclosed within cleanroom conditions under a single roof, able to simulate all the rigours of an actual flight into orbit, including vibration and acoustic effects, temperature extremes and, of course, exposure to hard vacuum.

MetOp-B’s Payload Module (PLM) was placed inside the Large Space Simulator (LSS) on 12 June. The LSS is the largest vacuum chamber in Europe: its cylindrical chamber can accommodate a double-decker bus standing upright.

MetOp is Europe’s biggest and most complex Earth observation satellite since Envisat. For convenience of testing, MetOp-B has been divided into two. The PLM, housing MetOp’s suite of meteorology instruments, is being put through its paces at ESTEC while its Service Module is being evaluated separately at Intespace in Toulouse, France.

Once preparations are complete at the start of July, the module will be subjected to thermal-vacuum testing in the LSS during a continuous 17-day period. It will be subjected to different thermal environments to validate its assembly.

The performance of the instruments mounted on the module will be checked thanks to a number of cold ‘blackbodies’ located very close to them and controlled at temperatures varying between –243°C and –183°C.

AMS-02 testing delivers decisive result

Back in March, the LSS housed a different guest: the Alpha Magnetic Spectrometer (AMS-02), a unique particle physics experiment looking for evidence of antimatter and dark matter. It is intended to be the Space Shuttle’s last ever cargo to the International Space Station.

Made up of elements from many European countries, AMS-02 was assembled in CERN in Switzerland before being shipped to ESTEC in mid-February for environmental testing.

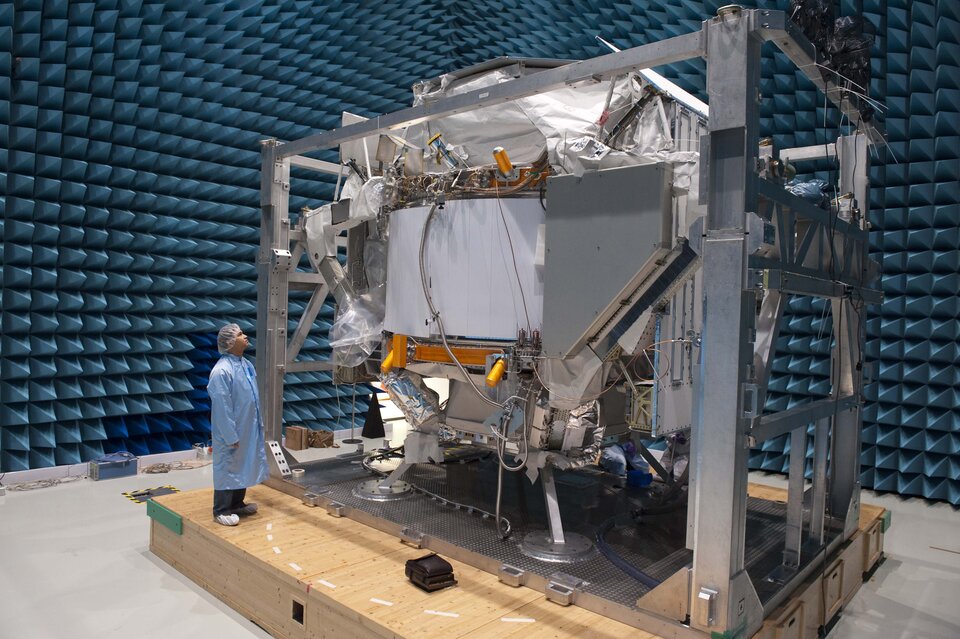

“AMS-02’s testing began with a session in our Maxwell test chamber, to confirm its electromagnetic compatibility with the Shuttle and ISS systems,” explained Mr Piret. This was important because AMS-02 includes a powerful magnet to bend the path of incoming charged particles on their way through a stack of detectors.

The initial version of the magnet was so powerful, in fact, that it relied on superfluid helium to achieve superconducting temperatures, down to just 1.8°C above absolute zero.

Next came thermal-vacuum testing in the LSS, to prove the thermal performance of all AMS-02 subsystems in space conditions. The results, coupled with the news that the Space Station’s lifetime is being extended beyond 2016, helped the team to decide to swap their original superconducting magnet for a permanent magnet previously employed in orbit during 1998’s AMS-01 Shuttle-based test.

This replacement magnet is less powerful but means that AMS-02 will be able to operate continuously on the Station for 10 years, versus three years or less for the original.

“The evaluation of AMS-02’s performance by the Test Centre proved very important for the payload, as well as for NASA’s Shuttle manifesting and ISS planning,” added Mr Piret.

“This demonstrates once again the critical importance of performing thorough testing of space hardware.”

BepiColombo among tests to come

The first part of the BepiColombo mission to Mercury is due to arrive in September. Japan’s Mercury Magnetospheric Orbiter will be the first specimen to experience the 14 kW/m2 illumination produced by the improved Sun simulator in the LSS – 10 times the strength of the Sun from Earth orbit. Soon after, the craft’s ESA-built sunshield will arrive for a tandem test.

At the end of the year Europe’s Mercury Planetary Orbiter is due at ESTEC for the same simulation. The remaining Mercury Transfer Module, which will transport these other elements to the innermost planet, will reach the Test Centre next year.

“The Sun test for BepiColombo has also been a challenge for the Test Centre,” explained Mr Piret.

“We will produce for them what must be the highest artificial Sun intensity a full satellite has ever been subjected to. If all the modules survive, the first challenge of the Sun simulation, they will have to be piled up on the shaker to demonstrate that they will survive the vibrations of launch.”

And demonstrating how the ESTEC Test Centre is also able to serve wider European industry, Airbus recently completed a complex set of vibration tests on a fuselage section using ESTEC’s largest vibration facility, called Hydra.

“All these activities are possible thanks to the competence and the motivation of the people working in the Test Centre. It is during such a period that you realise just how dedicated ESA and European Test Services staff who operate this facility really are.”