Space hinges

New tech 'hinges' on additive manufacturing

A new GSTP study with RUAG, has shown that flexible space hinges can be built using additive manufacturing.

A flexible pivot was developed and manufactured using powder-based Laser Metal Deposition (LMD) and tested on sample and demonstrator level, reaching TRL 4.

Flexible pivots are most commonly used in space for instrument mechanisms, such as the precise rotation of mirrors, but also for deployment of appendages and booms. But over many cycles they can wear out. The GSTP activity aimed to use additive manufacturing to develop and test a flexible pivot that had better surface quality and was less likely to fatigue.

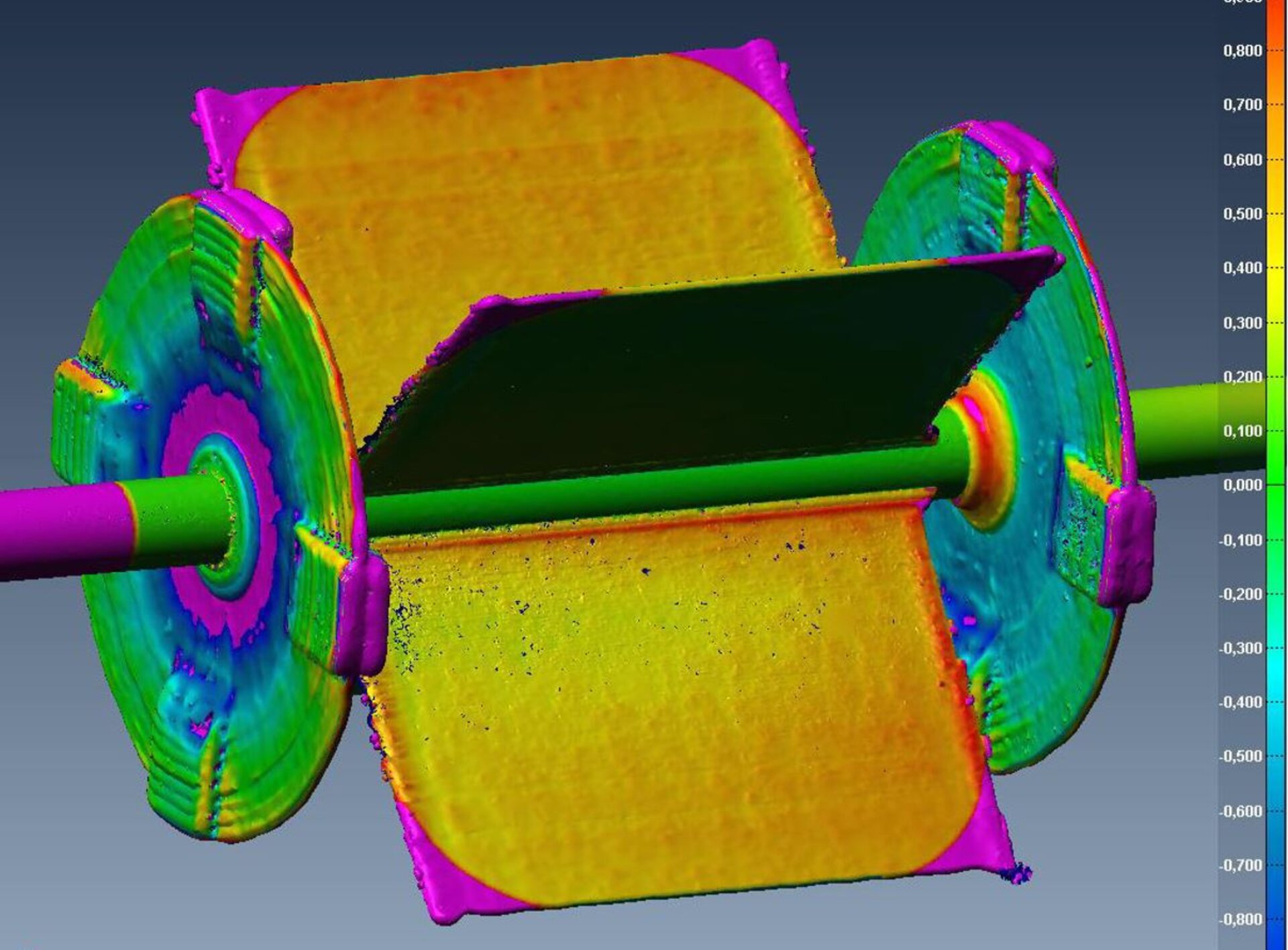

They built a pivot using powder-based LMD where the centershift and rotational stiffness were minimal but radial and axial stiffness was maximized. (The image above shows a scanning electron microscope photograph of the 316L-Si powder undergoing power characterization, including particle size and rheology analysis).

The team conducted many tests on their pivot to test whether or not the laser metal deposition technology was suitable to be used in fatigue critical items. The process included non-destructive tests such as crack and pore detection by metallographic investigation and CT scan.

They concluded that future development should focus on surface finish methods for multidimensional, dynamically loaded, thin and flexible elements for flexible structures and compliant mechanisms manufactured with Additive Manufacturing processes.

They also addressed the need for an end-to-end process for the qualification of thin walled, flexible elements produced via Additive Manufacturing. A follow on activity is being implemented in GSTP.

Contract G61A-036QTa closed in January 2019