Life support pilot plant paves the way to Moon and beyond

A pilot plant inaugurated yesterday in Barcelona, Spain, is testing regenerative life support system technologies that could one day recycle waste products and supply essential food, water and oxygen to humans living on the surface of the Moon or Mars.

MELiSSA, short for Micro-Ecological Life Support System Alternative, is an artificial ecosystem to recover food, water and oxygen from waste (faeces and urine), carbon dioxide and minerals. The laboratory will help in the development of technology for a future regenerative life support system for long-duration human space exploration missions, for example to a lunar base or to Mars.

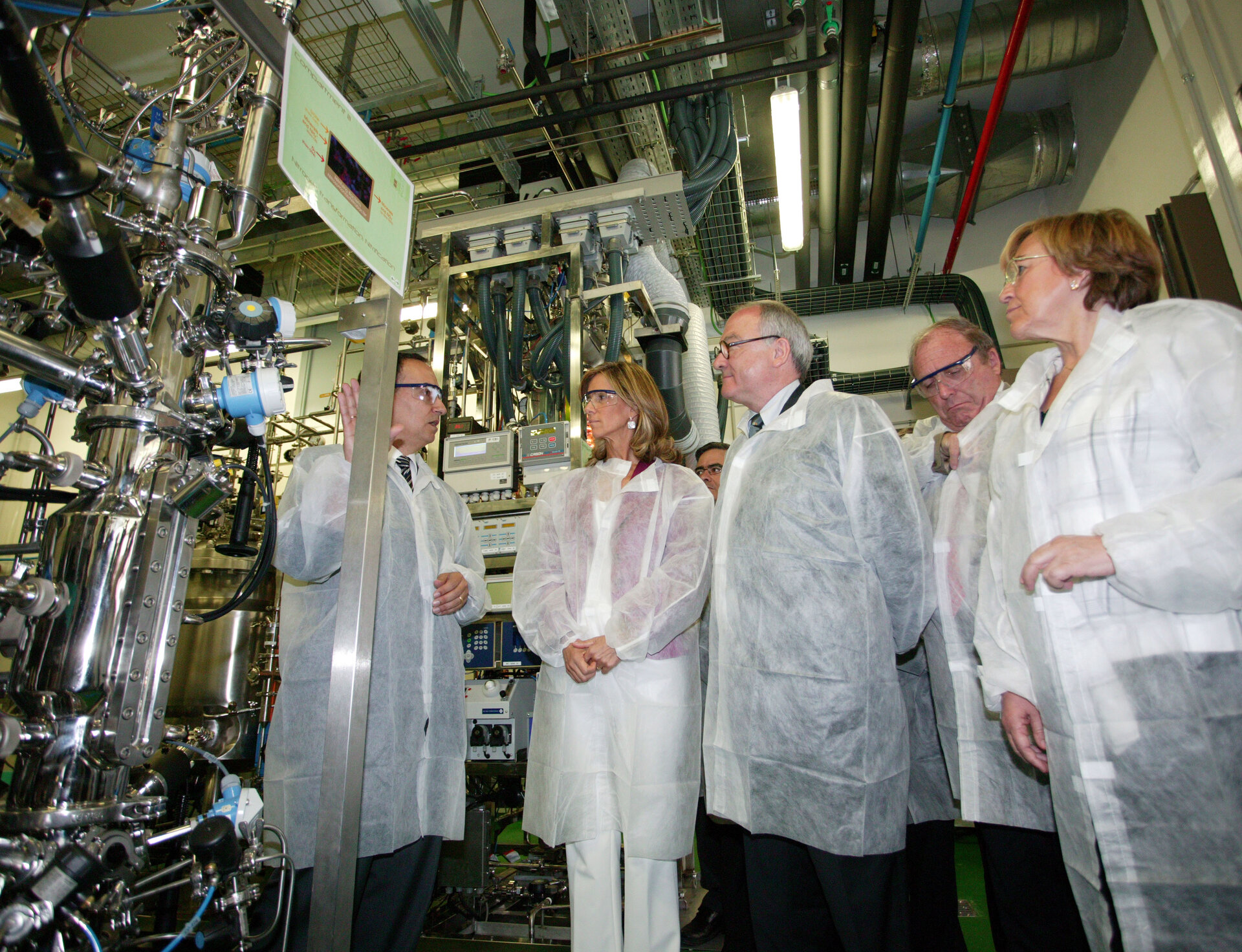

The second generation MELiSSA pilot plant is located within the School of Engineering at the University Autònoma of Barcelona (UAB), Spain. The MELiSSA project is partially funded by ESA through the Directorate of Human Spaceflight and the Directorate of Technical and Quality Management. The facility was inaugurated yesterday by the Spanish Minister for Science and Innovation Cristina Garmendia, ESA Director General Jean-Jacques Dordain and UAB Rector Ana Ripoll.

"The MELiSSA plant provides a world class research facility combining the expertise of many European countries, as well as Canada," said Dordain. "The validation of MELiSSA's highly regenerative life support processes is a mandatory step towards future long-duration human space exploration missions."

The pilot plant at UAB demonstrates the associated technologies with a 'crew' of 40 rats – together their oxygen consumption is equivalent to one person. This demonstration will last for more than two years – this length of time is considered representative of human space exploration missions. The rats will be kept under close veterinary supervision throughout.

MELiSSA goes further than other recycling systems used on Mir or the International Space Station that purify water and recycle urine and exhaled carbon dioxide, but do not attempt to recycle organic waste for food production.

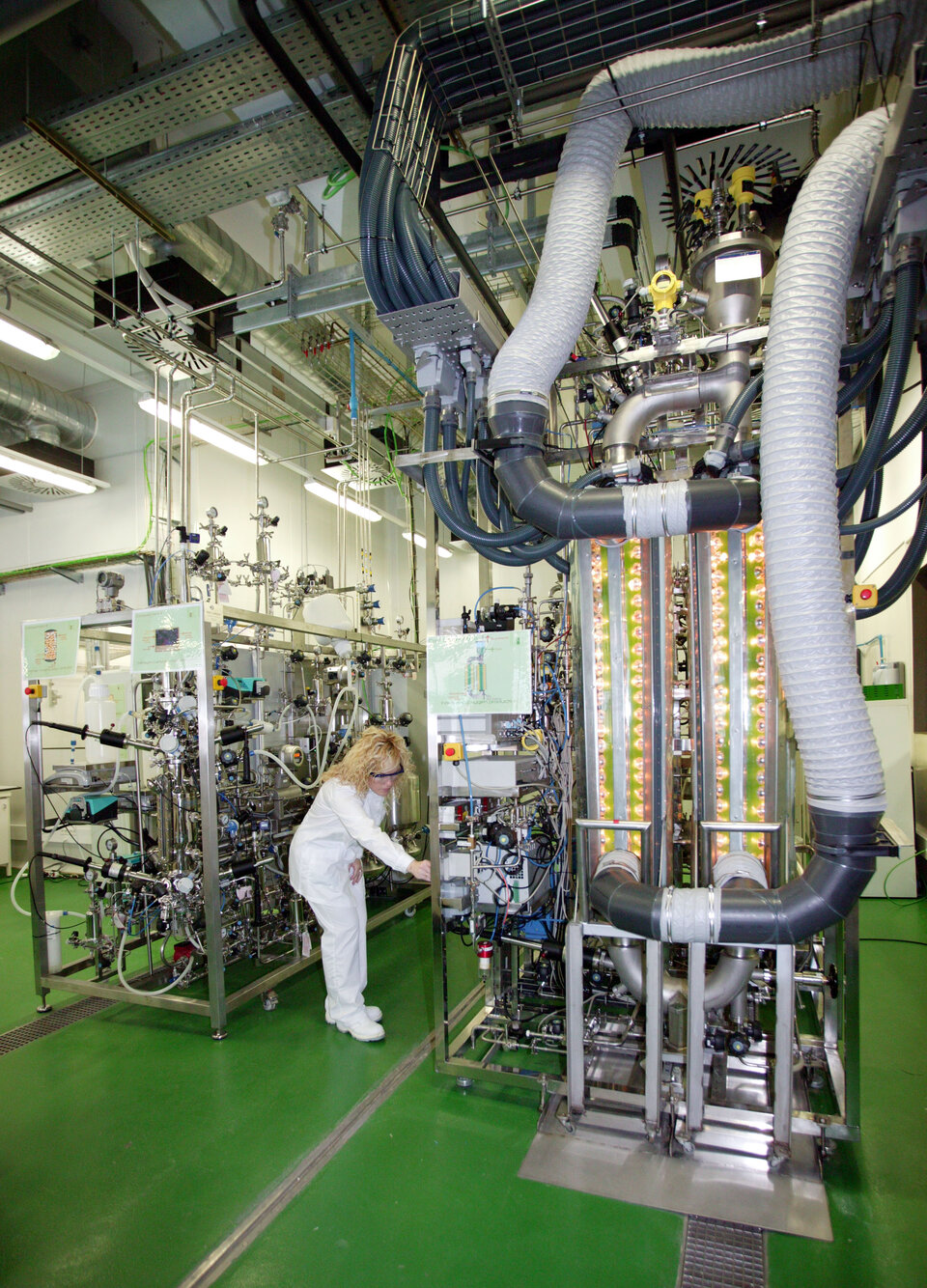

Based on the principle of an aquatic ecosystem, the facility consists of five interconnected compartments. In three of them, waste is progressively broken down by fermentation processes. In the fourth compartment, algae or plants are grown to produce food, oxygen and water. The fifth compartment is where the crew lives – rats in the case of this experiment and on real missions – the astronauts.

"I praise the progress made in the demonstration of the technologies which are the bases of the MELiSSA project. This is a key element in our strategy for human spaceflight and exploration. We now have to press ahead with a more stringent utilisation plan that takes into account the real needs of human missions in different scenarios," said Simonetta Di Pippo, ESA's Director of Human Spaceflight. "The Directorate will provide the required leadership to this very important project that is a demonstration of a successful partnership between ESA and national and local authorities. One more piece of the puzzle is falling into place to make Europe an even more important partner in future human spaceflight and exploration undertakings."

The first generation MELiSSA pilot plant, which began operating in November 1995, was gradually assembled together with components developed all over Europe. The preliminary achievements of the first pilot plant lead to the decision in 2005 to develop an improved facility.

The second generation MELiSSA pilot plant was built in 2006-2007 and will progressively incorporate newly designed compartments. The compartments will first be independently tested, characterised and optimised during the next 18 to 24 months. They will then be gradually interconnected in order to start a full-scale demonstration of MELiSSA in 2014.