First hot firing of European staged-combustion demonstration engine

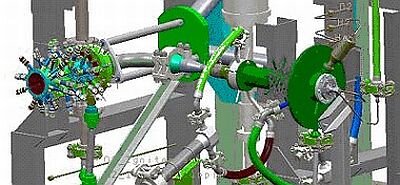

The first hot firing test of a reduced-scale demonstration version of a staged-combustion rocket engine has recently been achieved at the Lampoldshausen (Germany) test facility of DLR. This development work is part of ESA's Future Launchers Preparatory Programme.

One of the developments that will be necessary for Europe's Next Generation Launcher (NGL) is a new design of main engine. The Vulcain engine that powers Ariane 5 is approaching the limits of its design in terms of both thrust and overall performance. At present, there is no consensus on what is the 'best' technology to employ in the future. One objective of the Future Launchers Preparatory Programme (FLPP) is to enable an informed decision to be taken later in the NGL programme.

Choice of technology

Liquid-fuelled rocket engines can be classified according to how they derive the gases that power the turbine-driven pumps used to force the fuel and oxidant into the combustion chamber:

- open-cycle, gas generator - small amounts of fuel and oxidant are combined in a gas generator and the resulting hot gas flow powers the pump turbine before being vented near the main rocket nozzle

- closed-cycle, expander - after being used to cool the engine nozzle, the now heated and expanded fuel is used to power the turbine before being injected into the combustion chamber

- closed-cycle, staged-combustion - after being used to cool the engine nozzle, the now heated and expanded fuel is mixed with a small amount of oxidant and a fuel-rich (lower temperature) burn is carried out in a pre-combustion chamber; the output of this pre-combustion process powers the turbine before being injected into the main combustion chamber with the remainder of the oxidant

Europe has experience with open-cycle gas generator engines - Vulcain is an example of this type - and with closed-cycle expander engines - the Vinci engine uses this design and has accumulated more than 3000 seconds of hot firing tests.

Part of the work currently being undertaken in the propulsion area of the FLPP is the development of technologies and competencies for the next step: closed-cycle, staged-combustion engines.

Why staged-combustion?

The overall efficiency of a rocket engine is measured by its 'specific impulse' - the impulse (the change of momentum - or, put simply, the speed increase of the launch vehicle) that it can achieve per unit quantity of fuel. This is somewhat like the 'miles-per-gallon' or 'litres-per-100km' figures that are quoted for cars.

The specific impulse of a gas generator engine is inherently limited, while for the staged-combustion design, it increases with the combustion pressure. This provides opportunities for developing engines that need less propellant to perform a given task, reducing the propellant load and, as a consequence, the size and structural mass of the launch vehicle.

New fuels

The energy content and storage properties of the selected fuel have a major influence on the overall 'efficiency' of a launch vehicle. High energy content delivers high specific impulse but is not necessarily the best solution when viewed at system level. Hydrogen, the fuel used in the engines mentioned above, is now in competition with hydrocarbons such as methane.

Although hydrocarbons contain less energy per kilogram than liquid hydrogen, their higher density and less demanding storage requirements (they remain liquid at much higher temperatures than hydrogen), leads to reduced tank size and mass.

Enabling technologies

For NGL main stage propulsion, staged-combustion cycle engines and methane propellant are considered to be enabling technologies for increased performance, growth potential or cost reduction.

The recent test at Lampoldshausen has successfully shown the ignition and ramp-up of a hydrogen powered, staged-combustion demonstrator. This work is continuing and is being expanded to demonstrate the use of methane as a fuel.

ESA FLPP main stage propulsion development is being carried out by a consortium and co-contractor comprised of Snecma (France), Avio (Italy), and Astrium (Germany), supported by a team of nine other European companies and research bodies.