Latest pictures of CryoSat satellite in the clean room

While validation experiments get underway in the Arctic to ensure that the eventual data from ESA’s ice mission CryoSat is as accurate as possible, back in Germany, engineers are carefully piecing together the various components of the satellite in preparation for launch at the end of this year.

The images here show CryoSat nearing completion.

Most of the elements of the satellite have now been delivered to the prime contractor Astrium GmbH’s facility in Friedrichshafen, Germany. It is here, in the clean room, where they are currently being gently integrated into the spacecraft structure. Once this stage has finished, the complete satellite will undergo final testing at IABG (Industrieanlagen Betriebsgesellschaft mbH) in Ottobrunn, Germany before being shipped to the launch site at Plesetsk in Russia.

CryoSat will be the first Earth Explorer satellite to be launched as part of ESA’s Living Planet Programme. This mission is a direct a response to the issue of climate change and the effect that this may be having on the Earth’s polar ice masses. At the moment, it is unclear whether any reported change in ice cover is actually a result of global warming, inadequate observation techniques, or simply due to natural variability.

CryoSat, therefore, has been designed to determine rates of change in the thickness of polar ice sheets and floating sea ice. This data will help improve our understanding of the relationship between the Earth’s ice cover and global climate. To meet the challenge of accurately monitoring small changes in the elevation of the surfaces of sea-ice, as well as ice sheets on land, a precise radar altimeter has been especially designed to derive these much needed observations.

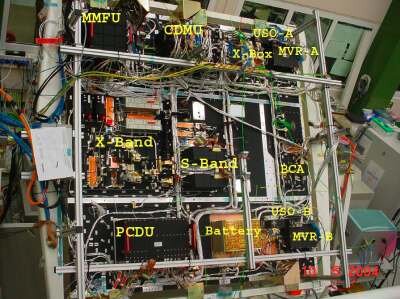

The current process of integrating the various components into the spacecraft follows a rigorous testing period. Mounted on what is called the Satellite Test Bed, the electrical units were first tested individually and then as a system. This procedure allowed work on the flight structure to continue uninterrupted. One advantage of this method of testing is that if an anomaly is discovered, it is much easier and less risky to rectify the problem than if the units were already mounted on the flight structure.

In parallel to the Satellite Test Bed activities, the cold gas propulsion system was integrated and tested on the CryoSat flight structure. The thrusters had first been sent to ESA’s ESTEC facility in Noordwijk, the Netherlands to be tested and to ascertain their optimum position on the satellite. With the propulsion system installed, it was then possible to assemble the flight harness.

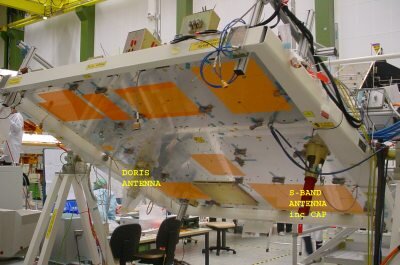

One particular important element that is being prepared ready for unit integration is the Nadir panel – this houses many of the electronic units. The procedure includes fitting heaters, ty-bases, harnesses and radiators. With the preparation of the Nadir panel completed, the flight units are carefully integrated on the Nadir panel. Preparation for environmental testing also means that many thermocouples have to be installed to ensure that thermal tests on the satellite are correct.

Once the units have been successfully fitted on the Nadir panel, it will then be integrated into the overall structure, along with the solar arrays and antenna bench. Then, in this configuration, CryoSat will be transported to IABG for final environmental and system testing before being shipped to the launch site.