Systems involvement in Additive Layer Manufacturing

Additive Layer Manufacturing (ALM) is one of the key technology roadmaps being developed in the frame of the clean space initiative at ESA. The benefits brought by this new manufacturing approach and respective extra design freedom can only be understood to their full extent if considered from a multidisciplinary system perspective.<p>

The CDF and Clean Space Initiative utilized the abilities of a stagiare to carry out the initial study into ALM. Lena Schützle was on a six month internship from the Technical University of Munich and had been working in the ESA Concurrent Design Facility (CDF) in ESTEC learning about concurrent engineering and participating in CDF studies.

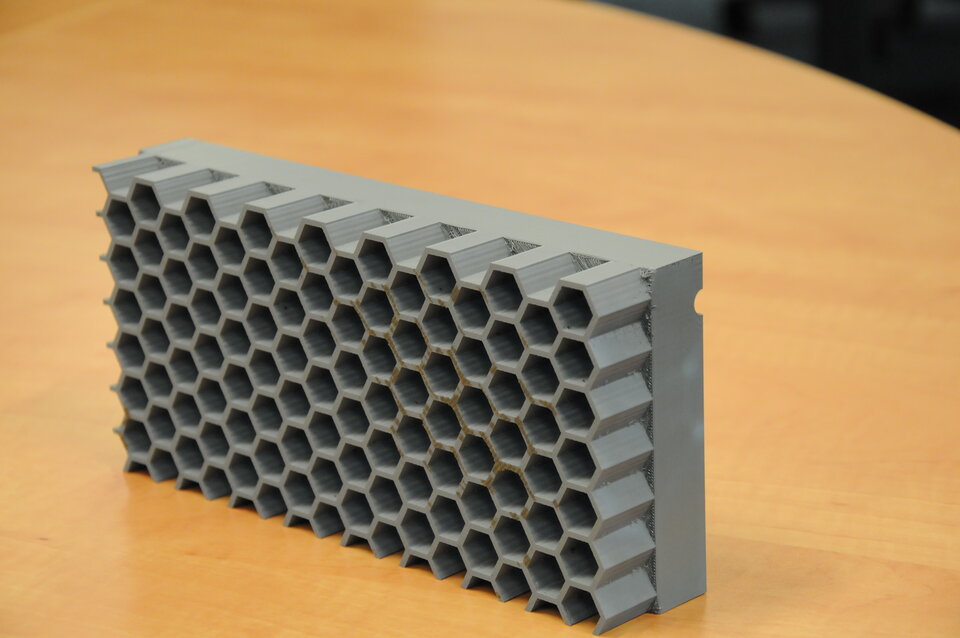

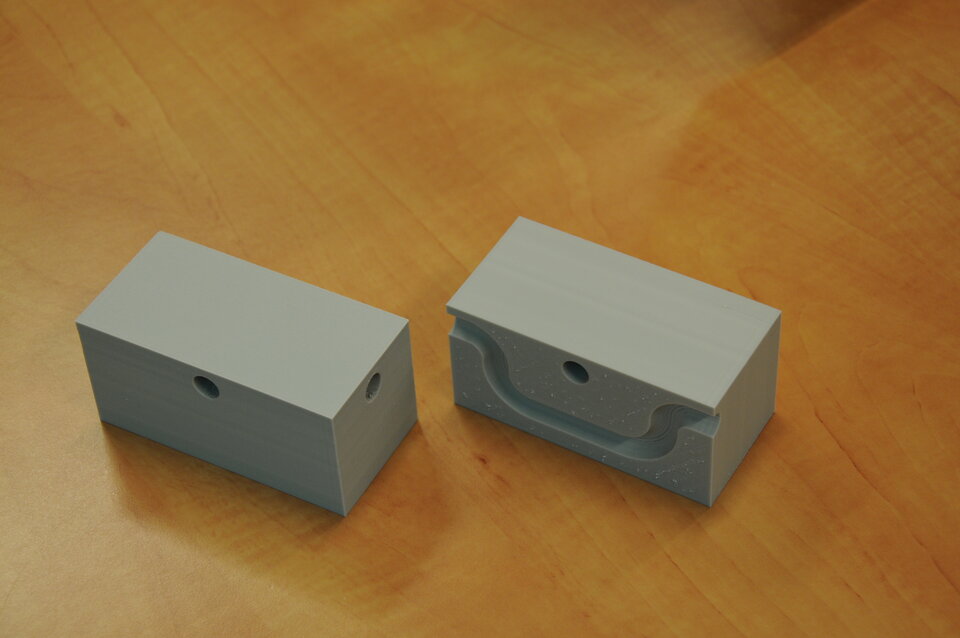

ALM is the umbrella term for several processes in which parts are being produced by adding successive layers of polymers, metals, ceramics and even composites. Instead of removing material from a block, this technology enables the manufacture of near net shape parts using almost only the amount of material that is necessary, hence reducing waste production.<p>

After an initial information gathering phase relating to different ALM methods and technologies and identifying the various projects within ESA dedicated to ALM applications for various specific parts, Lena organized a brainstorming on the question: “How could ALM help solving common challenges in telecommunication, science and earth observation?”. With fourteen participants from four different departments the aim was to look at the main design drivers on system level in order to see whether ALM could provide solutions to these challenges. Subsequently, Lena tried to bring the discussion up to a system level and to see whether there are even more benefits that ALM could bring. Several ideas were identified, one of which is the manufacturing of mirrors and mounting brackets out of the same material in order to avoid assembly cost and to diminish thermal mismatching. Also a consensus was achieved that ALM ‘shows high promise for improving the thermal system with i.e. integrated cooling channels and radiators with complex shapes.”

As well as enhancing the knowledge base within ESA and specifically within the Clean Space team relating to ALM and its system level integration, this has been a great opportunity for Lena to conduct an internship at ESA in the beginning of her studies. She worked with many experts from different domains and got to know the manner of working in a space agency. She said that “Working on a cutting edge technology like Additive Manufacturing has made my internship even more interesting and would definitely influence my future specialization at the university”.