Laboratories

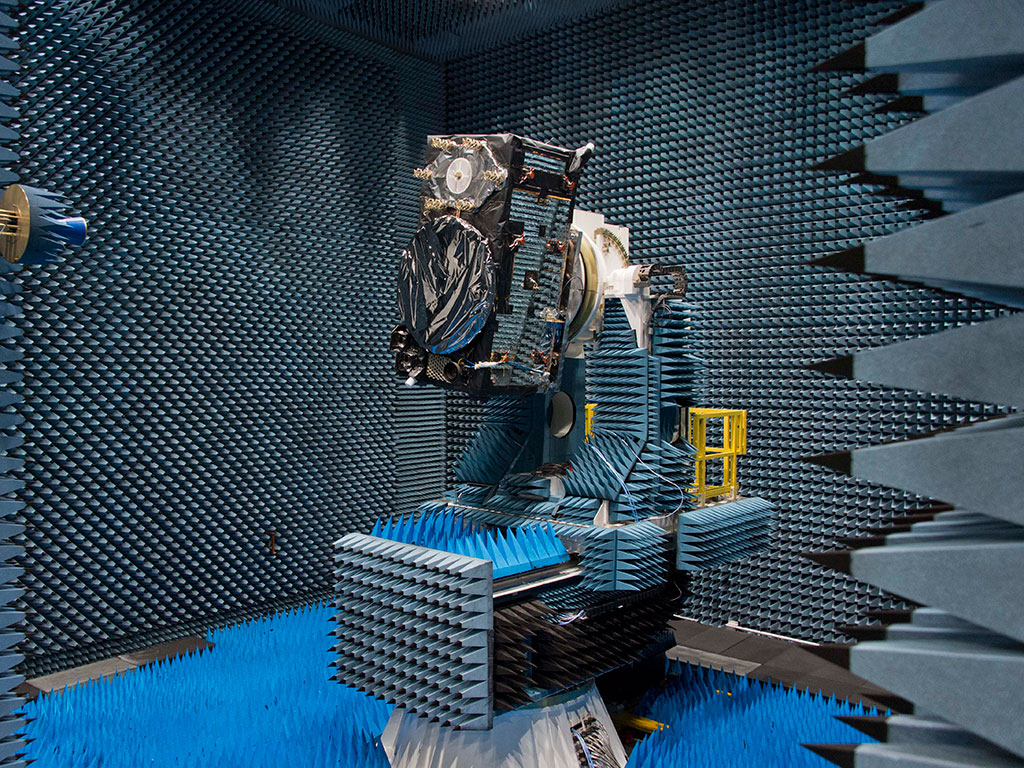

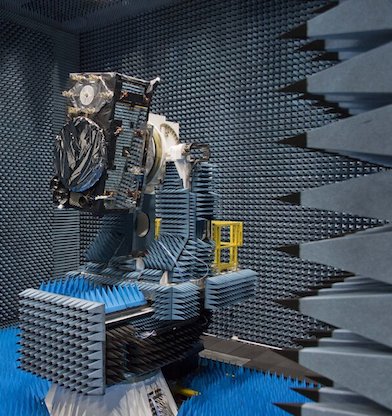

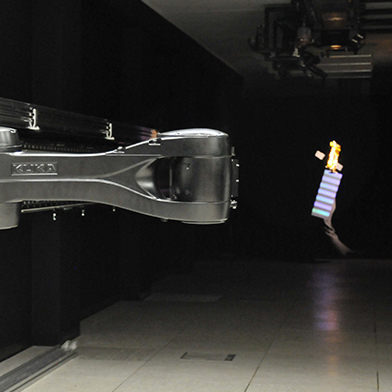

Advanced missions need advanced testing.

To save time and money, we offer external partners a unique infrastructure, which would not make economic sense to develop multiple times at multiple places for single missions

We have pooled resources to establish and develop world-beating test facilities that are available to all European space – and, indeed, non-space – companies or organisations.

ESA’s own R&D activities and technical standard-setting are supported through specialist technical teams as well as a suite of well-equipped laboratories at ESTEC and across a number of Member States that focus on all aspects of the space environment.

For missions, the labs examine each item, instrument and piece of software to be used in space, both individually and in conjunction, verifying its suitability for use by simulating the conditions experienced in space or during launch as closely as possible.

The labs’ work is not finished once a satellite is in orbit. They remain at the disposal of project teams to advise on the causes of mission anomalies, research potential fixes and disseminate lessons learned. These labs are available to service ESA missions and projects and to support research institutions and companies of ESA Member States.

1WORLD–CLASS TEST CENTRE

35LABORATORIES

22EXTERNAL STRATEGIC PARTNERSHIP WITH LABORATORIES IN ESA MEMBER STATES

50DIFFERENT FIELDS OF EXPERTISE

10COMPETENCE DOMAINS

Search the lab you need using the service or competence domain filter:

Our facilities share the same goal:

To enable and support future missions and keep Europe’s tech industry competitive.

We support the development of the newest technologies for Europe.