Vega’s virtual flights for stress testing

The successful launch of Vega VV01 from French Guiana earlier this year marked the first flight of Europe’s latest rocket design – at least in the real world. For Vega had flown thousands of times already within specialised virtual simulations created by ESA’s mechanical engineers.

It is not so often that the chance comes up to work on an entirely new launcher. Italian-led, but incorporating elements from all over Europe, much of the design of the 30 m-high four-stage Vega draws on decades of experience flying Ariane rockets: its first three solid-propellant stages are adapted from Ariane 5 strap-on boosters, with a liquid-fuelled fourth stage.

Yet Vega also incorporates a wide range of new materials to keep its own weight as honed as possible – the lighter its own mass, the more payload it can haul to orbit.

Most notably, Vega’s hull is woven from carbon fibre reinforced polymer (CFRP) then baked solid, a material more typically used for the load-bearing cores at the heart of telecom satellites or Formula 1 car bodies.

The resulting vehicle is three times lighter than an equivalent metal-hulled rocket, but with a strength-to-weight ratio almost five times greater than steel or aluminium.

Other novel materials included carbon/carbon and carbon phenolic composites, used for the all-important nozzles of the trio of solid stages.

It took years of work to verify that structures built of such novel materials had the combination of strength, stiffness and resilience needed to withstand the extreme forces of an orbital rocket launch, much of it performed before the final Vega components had even been manufactured, let alone put together.

Expert mechanical support

Like any other ESA project, the Vega team could count on the specialist technical support of the Agency’s Directorate of Technical and Quality Management, based at the ESTEC technical centre in Noordwijk, the Netherlands.

In particular, its 180-strong Mechanical Engineering department researches how manufactured structures and moving parts endure launch and space conditions.

The bulk of the department’s activities deal with satellite missions, but Vega presented a challenge of a whole different order, subjected to some of the most extreme forces imaginable during its brief hour of life. The department’s active participation in Vega began more than a decade ago, the team becoming involved both inside and out.

The Structures and Mechanisms division produced various simulations to understand how the structural design would withstand the strains of hypersonic flight, while the Propulsion and Aerothermodynamics division modelled the superheated environment during Vega’s engine burns.

Flight simulation

Keeping a launcher correctly oriented as it rises through the air is like balancing a pen upright on your finger, made more complicated by the fact that it is not a single item but four joined stages accelerating at hypersonic speed.

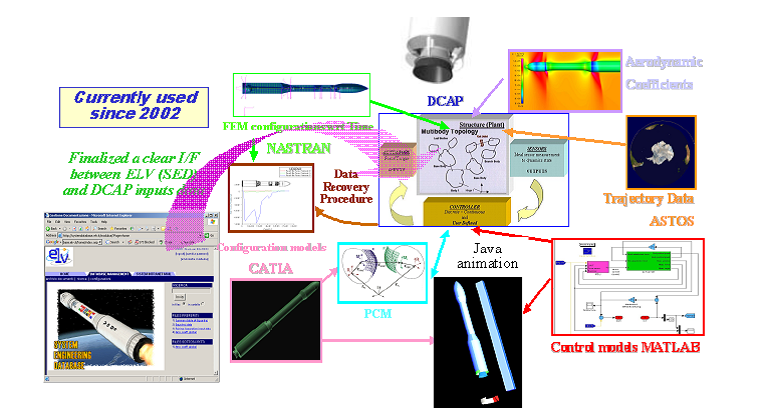

Back in 2001 the Structures and Mechanisms division used its long experience in multibody dynamics to create a Vega multibody flight simulator called VEGA-DCAP-sim.

“This was used to simulate a wide variety of launch vehicle dynamics and control problems,” explained Torben Henriksen, division head.

“The simulator’s backbone is the Dynamic and Control Analysis Package (DCAP), a multibody software developed by ESA together with industry and with more than 30 years of heritage in space applications.

“This software is a suite of fast, effective computer programs enabling the user to model, simulate and analyse the dynamics and control performances of coupled rigid and flexible structural systems subjected to potentially time-varying structural characteristics and space environmental loads.

“VEGA-DCAP-sim is able to reproduce in detail the performance of most of Vega’s key subsystems and disciplines, such as its trajectory, structures, configuration, mechanisms, aerodynamics, propulsion and guidance and navigation control, in a single simulation, assessing both nominal and off-nominal conditions.”

This flight simulator gave an authoritative overview of Vega’s overall flight dynamics and control performance in particular to forecast the payload excitations along the journey.

Separate software tools were also developed to model the mechanical performance of all elements of various configurations of launcher design, especially then correlated with the actual qualification tests.

Putting Vega under stress

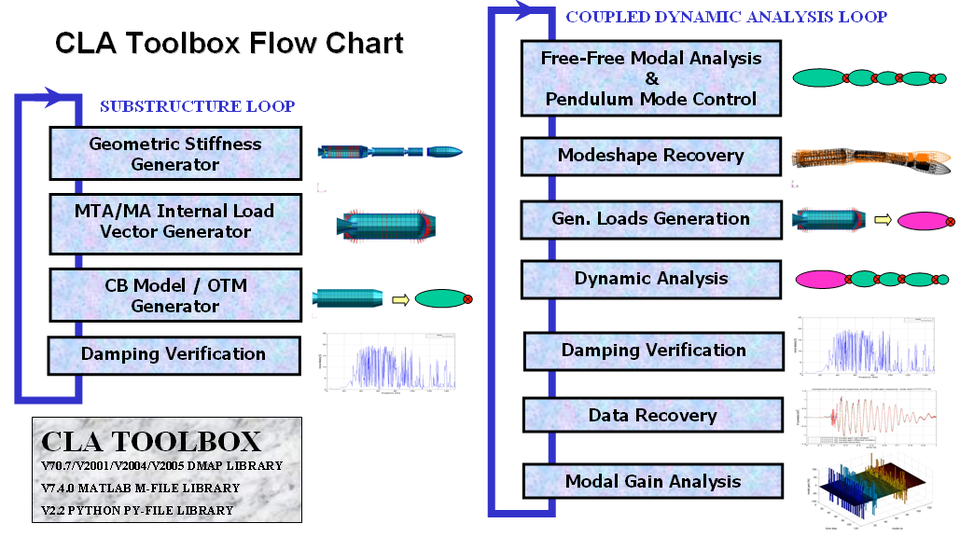

A technique called ‘finite element method modelling’ allowed the team to map a 3D grid of elements to initial computer aided design (CAD) Vega components, adding virtual flesh to CAD bones.

Engineers could then apply mathematical models of loads forces and structural behaviour to this ‘Coupled Loads Analysis’ CLA tool, creating a virtual representation of the launcher to demonstrate how it will bend, shake or deform across a range of stress conditions.

And once initial firing tests were performed, the team developed a separate ‘Operational Modal Analysis’ OMA tool to identify the main vibration characteristics of the solid motor rockets.

All structures have particular resonance frequencies derived from their materials, mass and shape, in principle like tapping a wine glass.

OMA was used to build up a complete picture of Vega’s resonance, and verify the dynamic correlation of the staged models. Would they fly together satisfactorily or give each other the shakes?

“This CLA tool was established in cooperation with European Launch Vehicle (ELV), the industrial prime contractor, and has since been delivered to Arianespace for Vega payload mission analysis, to verify the kind of ride a given satellite will experience,” said Torben.

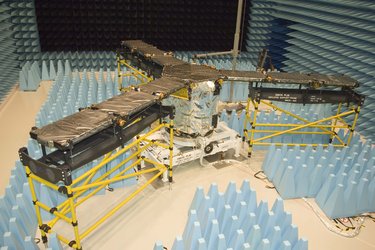

“In addition, CLA has also been employed in-house to predict the mechanical environment for planned Vega payloads such as the LISA Pathfinder technology demonstrator, the ADM Aeolus wind-mapping mission, the Sentinel-2 and –3 Earth-observing missions and the Intermediate eXperiment Vehicle reentry vehicle.”

| This article continues... |

|

| Next |

|