Cryogenic testing of a Brazed Optical Quality SiC Mirror

| Programme: | GSTP | Achieved TRL: | 5 |

| Reference: | G512-007MM | Closure: | 2015 |

| Contractor(s): | AMOS (BE) | ||

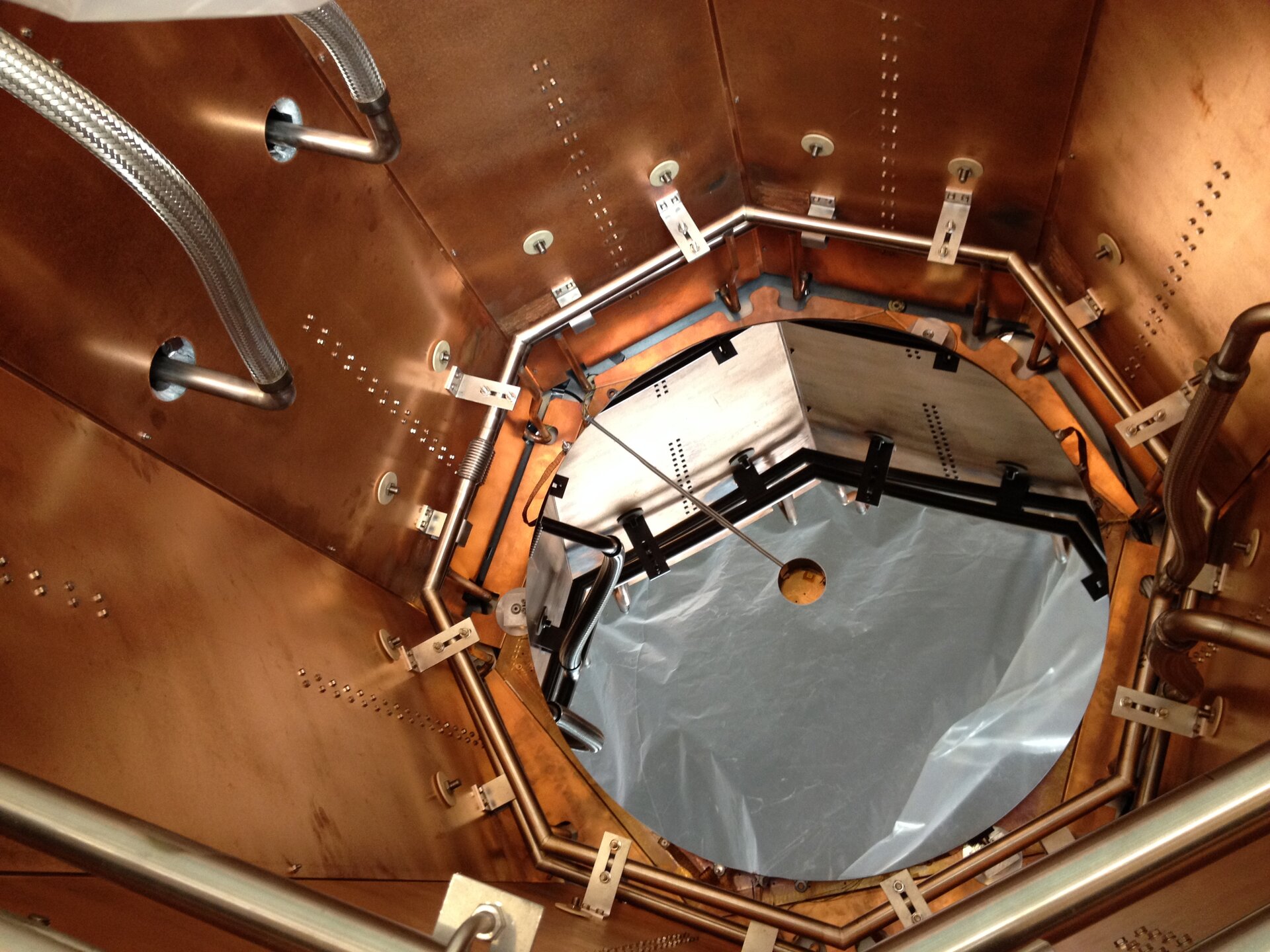

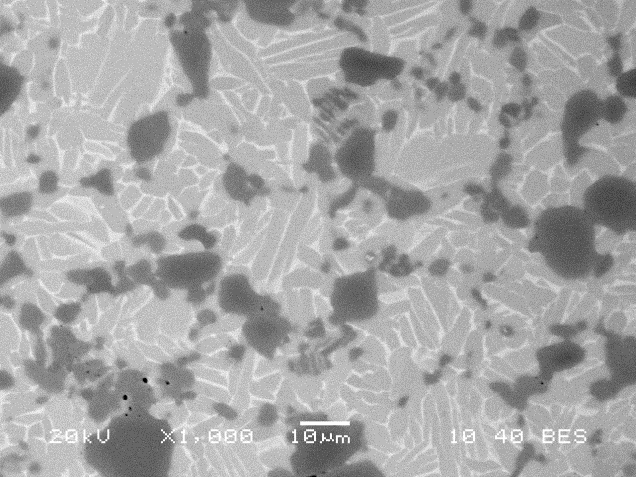

A 950mm diameter brazed SiC mirror had been manufactured and polished consisting of three individual petals brazed together. It has been shown that an excellent surface form can be achieved in ambient environment despite a different micro-structure of the individual petals. Space application of such mirror will require such quality also at low temperatures, in particular, for science missions.

Objectives

Test whether the different materials combined in this mirror (SiC, brazing agent, CVD SiC cladding layer) will induce distortions of the mirror limiting or preventing application of this mirror technology at low temperatures.

Achievements

The test was performed down to a temperature of 120K. The surface figure was degraded by 5.8 nm rms with respect to room temperature. This value is in line with FEM predictions and perfectly acceptable for optical telescopes.

Benefits

This test proved that this technology could be employed for optical space telescopes operating in the visible or ultraviolet without significant impact on the imaging performance.

Next steps

A potential follow-up would be the manufacturing and testing of a larger mirror.