Development and Characterization of Advanced Metal Matrix Composites

| Programme: | GSTP | Achieved TRL: | 5 |

| Reference: | G517-030QM | Closure: | 2016 |

| Contractor(s): | Tecnalia (ES) | ||

Adding ceramic particles is the only means to increase the specific properties of the metallic materials used in space industry. However, such addition needs to be carefully evaluated as it often has some adverse effects prohibiting the use of the composite. Advanced processing are required to obtain materials with the desired set of properties.

Objectives

To develop and characterise particle reinforced titanium alloy. To demonstrate the use of the material in combination with another type of titanium reinforced material containing monofilaments instead of particles.

Achievements

- Two processing routes and two reinforcements have been evaluated

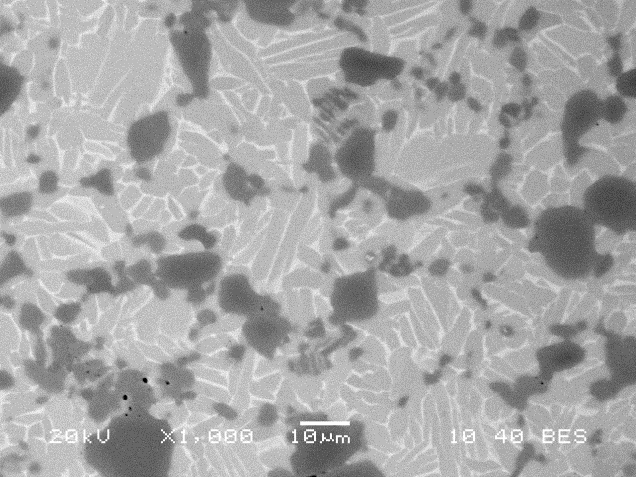

- An end-to-end process has been successfully developed to include 10% of TiC particles into a Ti6Al4V matrix based on SHS (Self-propagating High-temperature Synthesis)

- The material has been mechanically and microstructurally characterized. It is resistant to Stress Corrosion Cracking and can therefore be used for structural applications

- The material has been successfully brazed to monofilament reinforced Titanium made by TiSIC (UK) the junction has been characterized

-

Technology demonstrators were produced

Next steps

Improve the brazing process between the 2 materials and expand the range of potential applications.