Banishing explosive sparks in underground mines

Vintage space technology was dug up recently to make mines around the world safer by reducing the risks of explosions.

Deep beneath Earth’s surface, mining equipment is just like much other modern machinery – computer screens show the operators what’s going on. Under ordinary circumstances, glass screens would be ideal.

But in a mine, “Glass is difficult, because it breaks too easily,” says Johannes Koenig, an engineer at German mine-equipment manufacturer Marco Systemanalyse und Entwicklung GmbH.

Plastic screens, though, have a major drawback: they build up a static charge when touched, potentially creating a tiny spark like the one you get when you walk across a carpet then touch a metal door handle.

In mines, sparks can be disastrous. That’s because tunnels filled with clouds of fine coal or mineral dust are explosions waiting to happen. So screens made of scratch-resistant plastic must be protected in some way.

Marco engineers worked with ESA Technology Transfer Network’s MST Aerospace to find a solution. With MST’s help, they connected with MAT PlasMATec GmbH in Dresden, Germany, who years ago developed coatings for space.

“We saw that the coatings developed by PlasMATec for spacecraft could provide an intelligent solution to Marco’s mine problem,” saidDr Werner Dupont from MST Aerospace.

Space technology gets new life

PlasMATec’s experience with transparent coatings stretches back to before the 1989 fall of the Berlin Wall. Engineer Andreas Mucha was part of a Soviet-era team that pioneered indium–tin oxides (ITOs) to coat lenses and windows for spacecraft.

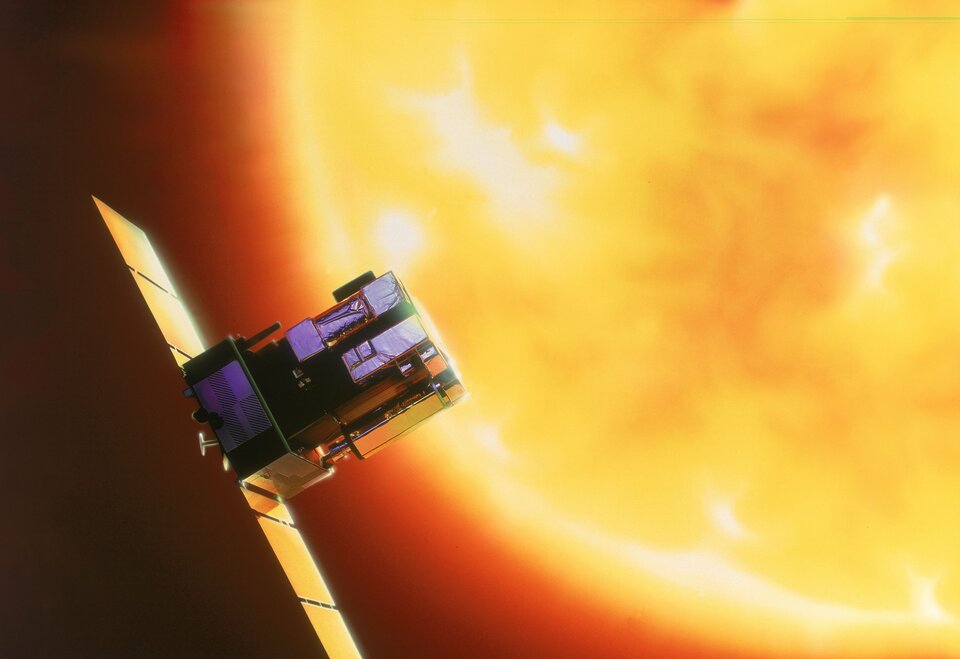

Similar coatings were used later on ESA’s SOHO satellite for thermal control of the payload pointing towards the Sun, and on Galileo’s laser retroreflector array.

Now used in everything from liquid crystal displays and touch panels to solar cells, ITOs conduct electricity and can be applied to surfaces as a transparent, thin layer.

The aerospace use of the technique was first developed for a space camera built by Karl Zeiss Jena for the Soviet space programme. In 1976, the Soyuz-22 manned spacecraft carrying the East German MKF-6 multispectral sensor camera spent eight days in orbit, taking nearly 2500 pictures of Earth. Later, another MKF-6 camera was mounted on Russia’s Mir space station.

Dr Mucha and his colleagues coated the MKF-6 lens with a very thin layer of ITO – just a few hundred nanometres thick – to give it a tiny bit of electromagnetic resistance. In space, the coating allowed the lens to be heated slightly via an electric current, to prevent condensation.

Space experience was the right solution

PlasMATec’s experience from Mir helped them to repurpose the transparent layer of indium and tin for Marco’s mining equipment.

“We coated their polycarbonate screens with basically the same conductive iridium–tin oxide layer we once developed for the lens of the MKF-6 space camera,” explained Dr Mucha.

The conductive coating prevents electrostatic charge from building up on the screen, in turn banishing sparks – and preventing underground explosions.

“A conductive film gives the possibility to have no electrical charging – or sparks – if you brush it with your hands,” Dr Mucha said. “It’s a different purpose than for space, but the same process.”

MST Aerospace is the German partner in ESA’s Technology Transfer Network set up by the Agency’s Technology Transfer Programme Office in 13 European countries, supporting non-space industry to identify solutions among the thousands of ready available space technologies.