ESA BIC Kumovis: a game-changing 3D-printing technology for medical products and implants

The ESA Business Incubation Centre (ESA BIC) Bavaria start-up Kumovis has developed a novel 3D-printing fused filament fabrication technology to produce medical products and implants. Meet them at ILA Future Lab ”FUEL FOR INNOVATION”.

3D-printing is seen as a promising and game-changer in production with its broad spectrum of applications leading to a double digit market growth. Especially for medical applications 3D-printing will be a key technology, as small series products as well as individualized implants cannot be produced economically with current manufacturing processes, such as milling, laser sintering or injection molding.

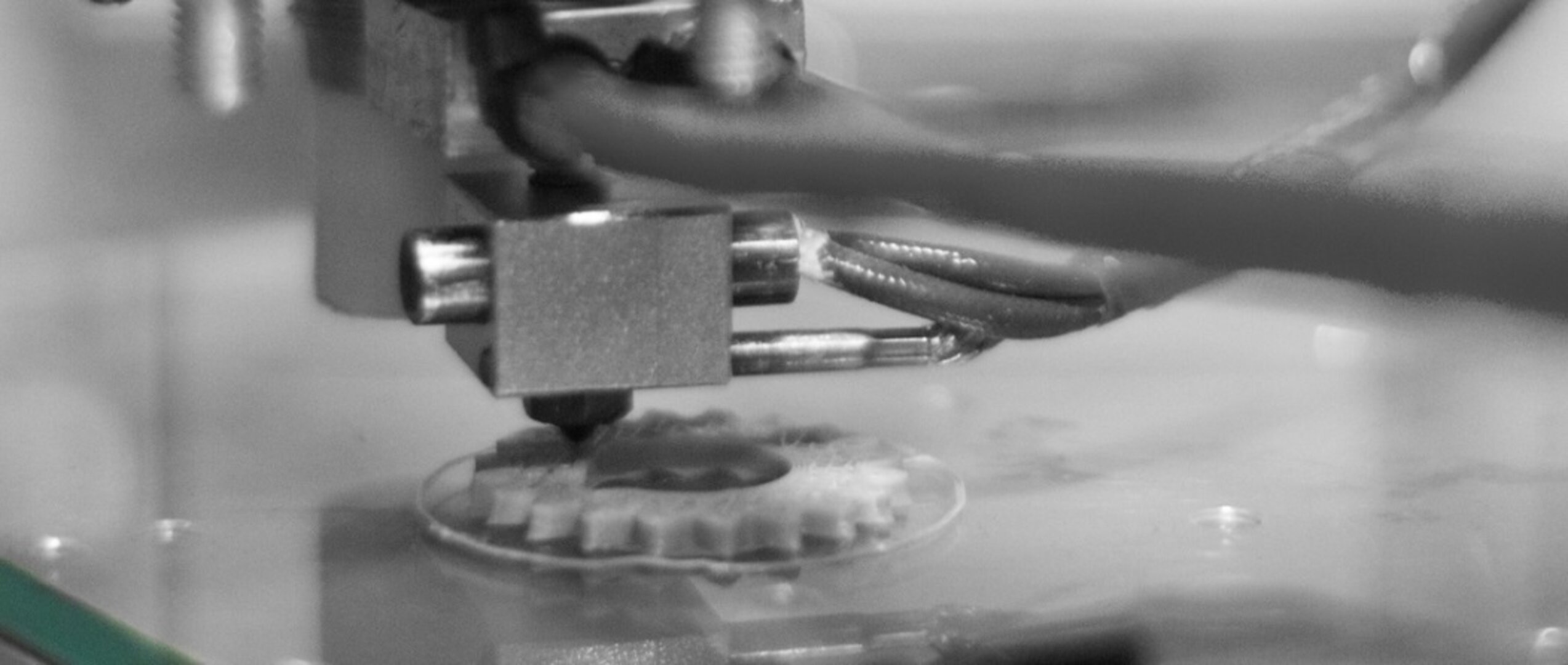

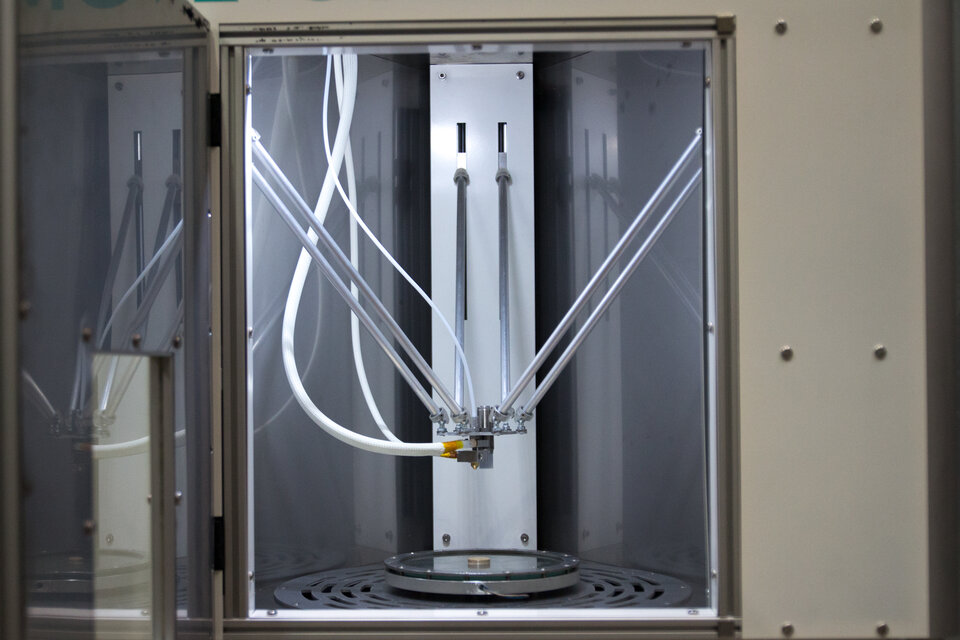

Kumovis new 3D-printer is based on FFF (Fused Filament Fabrication) for the production of medical products. The printer enables an economically feasible processing of medical-grade high performance plastics such as PEEK (polyetheretherketone). Three relevant patents currently protect the Kumovis technology.

On one hand, this results in an optimization of material mechanics. On the other hand, it enables a particle free-production that leads to high quality parts. Integrated process monitoring ensures the validation and precision needed for regulated branches such as medical technologies or aerospace.

This enables patient specific implants and increased functional integration, for example, by lattice structures for implants, which make bone in-growth possible. First possible applications for additive manufactured polymer products in aerospace are interior parts, brackets, or connectors.

“The 3D printing system is currently undergoing further development into a pre-series product that we test with four selected pilot customers starting in August 2018,” explained Alexander Henhammer from Kumovis.

“Here we will obtain direct customer feedback and optimize the series product. From March 2019, we commercially distribute the printing system to nine customers to parallel set up a well-functioning service and maintenance network.

“For the year 2020, our goal is to sell 26 printing systems and to continue with increased annual growth of 100% over the first 3 years.”

Founded in October 2017, the company poses all the necessary skills in the areas of materials science, additive manufacturing, mechanics, mechatronics, medical technology, administration and business development. In addition, employees in the field of IT and electrical engineering and process technology will support the team from September 2018.

The long-term goal of Kumovis is to take a leading role in the field of additive manufacturing of high-performance plastics for medical technology and other regulated branches.

ESA BIC Bavaria and the ESA BIC network

Kumovis is now hosted at the ESA Business Incubation Centre (BIC) Bavaria.

ESA BIC Bavaria is part of ESA´s Technology Transfer and Business Incubation Space Solutions Programme, which has created the world’s largest ecosystem for space related Entrepreneurship. The 18 ESA Business Incubation Centres (ESA BICs) support 160 companies per year and more than 600 new start-ups have so far been fostered.

At the ILA Future Lab ”FUEL FOR INNOVATION” meet Kumovis and other disruptive ESA start-ups together with Head of ESA Technology Transfer and Business Incubation Centre Office Frank M. Salzgeber, ESA BIC Manager Frank Zimmermann and Sabine Dannelke, the Head of Division Satellite Navigation/Galileo, Digitalization of Public Transport at the Federal Ministry of Transport and Digital Infrastructure in Berlin, Germany,

The ILA Future Lab ”FUEL FOR INNOVATION” takes place in the FORUM Hall 2/204 at ILA in Berlin on Thursday 26 April 13:15 – 14:45.