ESA BIC Touchless Automation: Smart production by levitation

The ESA Business Incubation Centre (ESA BIC) Switzerland start-up company Touchless Automation picks-up, moves and positions items without touching them. Meet them at ILA Future Lab ”FUEL FOR INNOVATION”.

The Swiss company has developed an innovative tool that allows manipulating objects without contact. This means that it can move an object from A to B without touching it.

The tool can easily be implemented in almost any industrial assembly station dealing with components in the range from 0.1 to 20 millimetres.

Furthermore, there is no limitation on the handled material. Objects could be made of any possible material, from metal to epoxy, from glass to plastic.

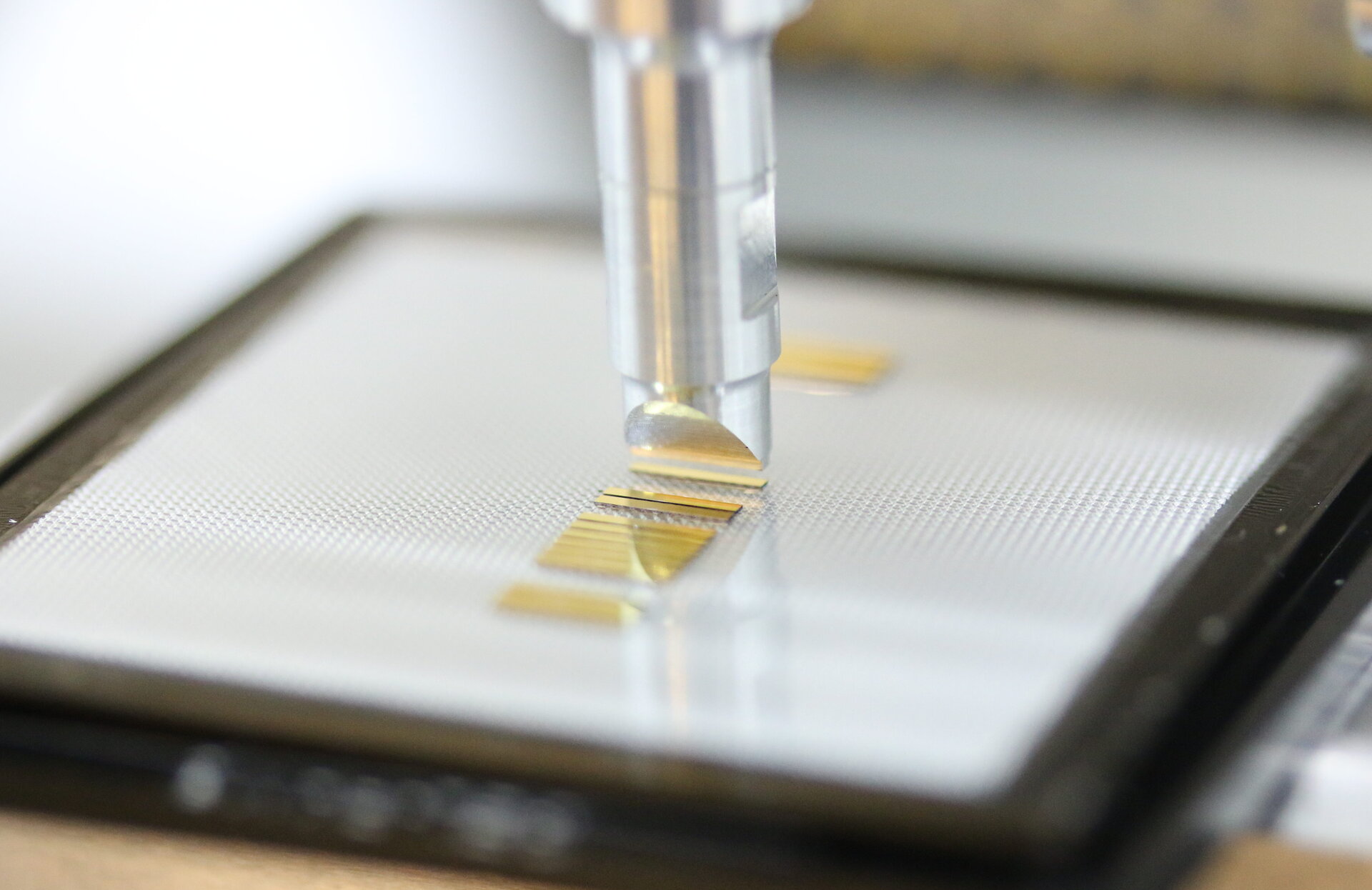

The technique invented is done using the combination of vacuum and ultra sounds. The result is that the component levitates.

In addition, the component auto-aligns to the tip as an auto-centering effect happens. No limitations on the material to be handled, however it works best with flat components

This new technology allows for the first time a non-destructive touchless handling of micrometer parts with nanometer surface structure.

Too small for conventional industrial handling

The market is pushing companies towards solutions with even smaller features. For Internet of Things` applications, some chips are smaller than half a millimetre.

Touchless Automation innovative technology is able to manipulate a chip with dimension smaller than a grain of sugar, correctly picking it up and placing it with an accuracy never reached before.

“Our purpose is to bring the Swiss precision to the next level and unlocking its potential for all industries that could benefit from it,” said Fabio Depetris, CEO Touchless Automation.

Placing the components with the right precision is never an easy task. Many factors such as adhesion forces or capillarity come into play. The root of all these issues is that the contact is necessary to move and place a component.

As soon as the Touchless Automation tool is turned on, the component aligns itself automatically to the tip of the tool. Any misplacement in position or angle of the component is corrected - this effect turns out to be especially effective when handling tiny components. The lack of adhesion forces and this alignment effect combined together, allow for a very high placing positioning.

ESA Business Incubation Centres – ESA BICs

The Technology Transfer and Business Incubation Programme Office of the European Space Agency manages the Space Solutions Programme, which has created the world’s largest ecosystem for space related Entrepreneurship. The 18 ESA Business Incubation Centres (ESA BICs) support 160 companies per year and more than 600 new start-ups have so far been fostered.

At the ILA Future Lab ”FUEL FOR INNOVATION” meet Touchless Automation and other disruptive ESA start-ups together with Head of ESA Technology Transfer and Business Incubation Centre Office Frank M. Salzgeber, ESA BIC Manager Frank Zimmermann and Sabine Dannelke, the Head of Division Satellite Navigation/Galileo, Digitalization of Public Transport at the Federal Ministry of Transport and Digital Infrastructure in Berlin, Germany,

The ILA Future Lab ”FUEL FOR INNOVATION” takes place in the FORUM Hall 2/204 at ILA in Berlin on Thursday 26 April 13:15 – 14:45.