Space brings savings to offshore oil and gas

Software for building ESA spacecraft is helping to improve safety and drive down costs for engineers operating deep sea oil and gas installations.

The expense of extracting energy from under the sea and the potential for fire or oil spills should things go wrong mean that companies are always looking for better ways to operate offshore installations.

Now, the EDMTruePLM™ (TruePLM) product lifecycle management tool, developed for ESA spacecraft programmes is improving efficiency for oil and gas industries.

Having spent years working with ESA on their Cassini–Huygens and Envisat satellites, Sverre Samdal from Jotne Industrier, a Norwegian company primarily involved in energy exploration, saw how TruePLM could also work for offshore industry because, “spacecraft and underwater machines present similar technical challenges.”

“Every project, whether it’s a satellite or an oil rig, generates piles of documentation from designs, calculations and testing to contracts and emails,” says Sverre.

“The problem is keeping track of it all when there are thousands of people in different companies using different systems. It gets complex, time consuming and expensive.”

Engineers estimate they were previously wasting a third of their day searching for paperwork, manually duplicating information between systems or decoding outdated software.

Deciphering formats with space

Complex mega-structures like oil rigs are built to last for 40 years or more, yet the systems for maintaining them are not. Formats are quickly outdated as new software hits the market every year.

The challenge is to manage all the information over decades in such a way that it is always at the fingertips of engineers both for maintenance and emergency intervention.

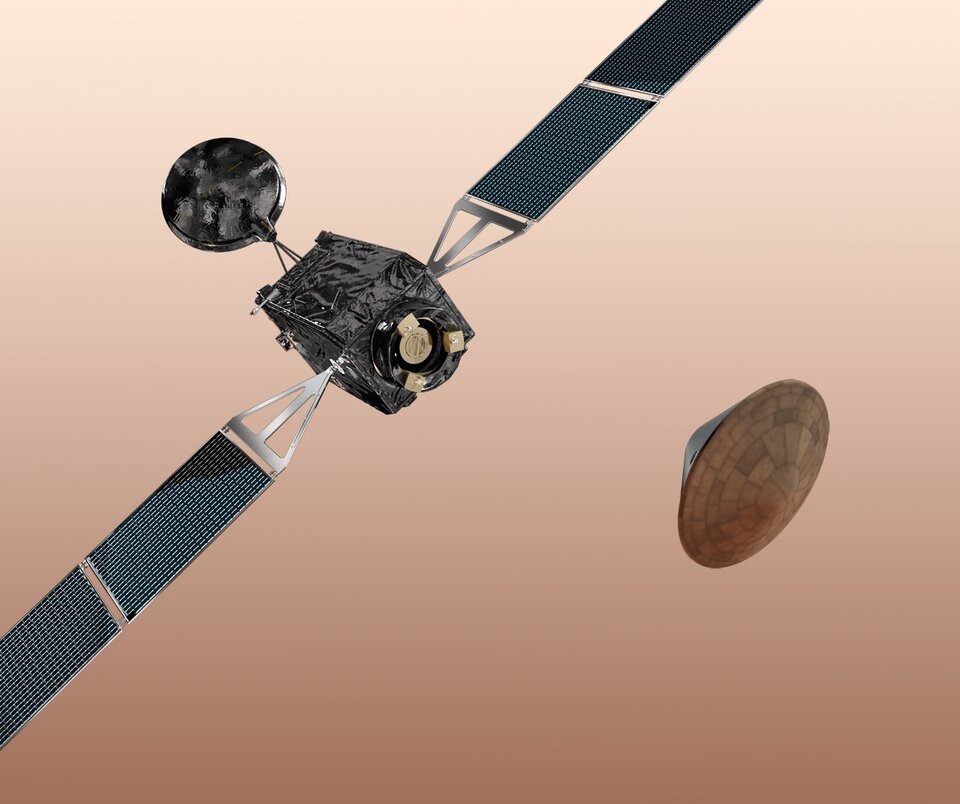

ESA had a similar problem: tracking all the documents throughout the 10–20 years of a spacecraft’s life.

In a bid to simplify things, they contracted Jotne to design a new application for engineers to process, share and store everything about the spacecraft in one database and retrieve it whenever they needed, from its conception to decommissioning.

“At ESA we support interoperability and openness and we were looking for an effective data archive that we could reuse for all our projects across their whole lifecycle, without incurring heavy software and hardware costs every time we started a new project,” explains Massimo Bandecchi, Head of ESA's Concurrent Design Facility.

Right now, TruePLM is proving a useful tool for ESA’s ExoMars planetary protection database, to manage the vast amount of information gleaned from testing Europe’s rover in the manufacturing process, to prevent any unwanted microorganisms from stowing away on board during its journey to the red planet.

TruePLM has some clever strings to its bow. Unlike most of its competitors, it is open software built on international ISO standards. “That means it’s free from proprietary constraints and is interoperable,” says Jotne’s Vice President, Kjell Bengtsson.

“TruePLM can translate all the formats used by different software and computer systems. And because it is all stored in one place, it’s much more efficient. You just input the information and anyone can access any document at any time during the lifetime of a system. It’s futureproof!”

Sverre Samdal adds, “We don’t have to worry about a software manufacturer shutting down and being unable to open a file in 30 years’ time.

“TruePLM can understand any format, however old, and because we can move information between different systems, we will always be able to share it. It’s a thoroughly modern interface.”

That means faster fault-finding, greater reliability and improved safety.

Advanced space solution for offshore systems

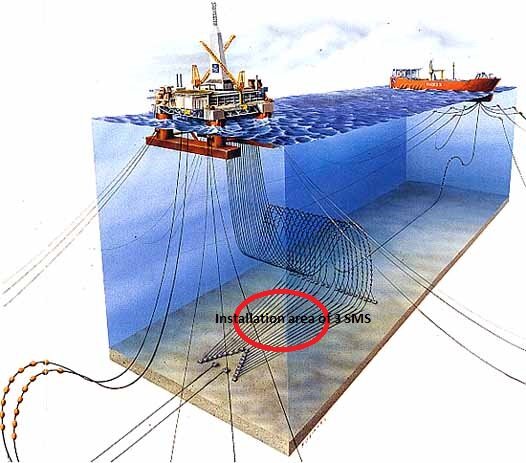

One of the biggest challenges of deep-sea mining is to keep equipment safe and reliable for many years in the harsh yet fragile environment under the ocean. Engineers need all the documentation to hand, even if it was originally produced years ago.

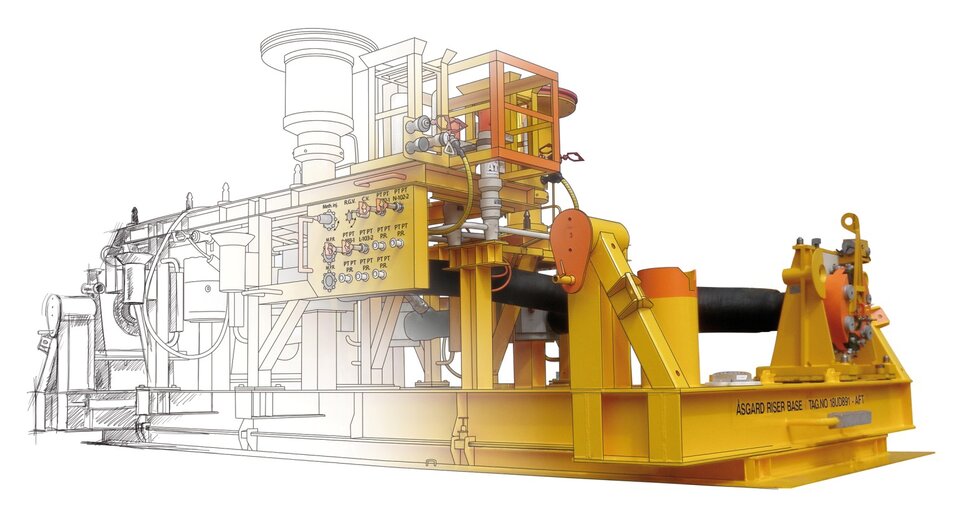

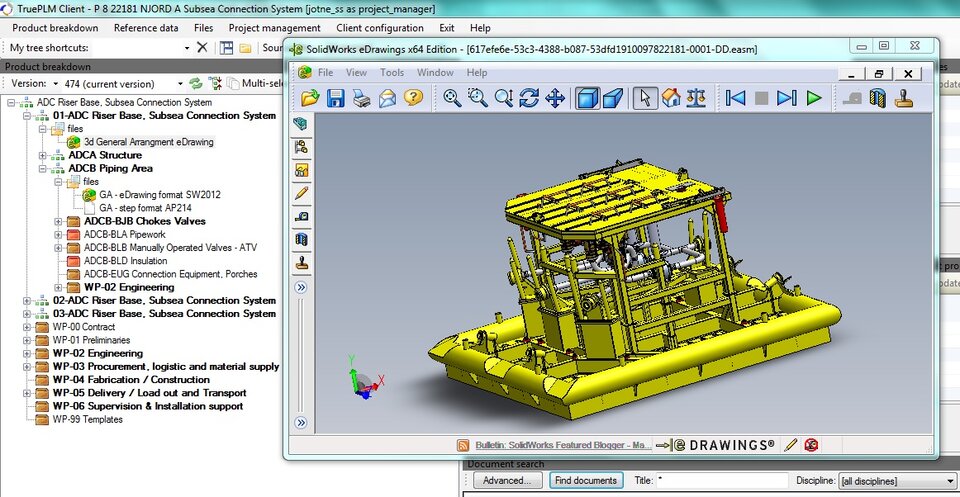

Here, TruePLM has is proving its mettle. Having served on projects for Norwegian energy multinational Statoil in the North Sea, it is now also used for Houston-based Oceaneering in developing an advanced garage for a remotely operated underwater vehicle.

“Also, in the North see, we are using TruePLM for manifold pipeline connection systems which are the building blocks for deep-sea infrastructure, as well as for pipeline inspection and maintenance equipment for the Eldfisk and Svalin oilfields,” says Sverre.

All complex structures are made of many parts. To keep track of them, TruePLM uses a master data unified repository with all the information in one place. Like a family tree, it allows you to search for the tiniest detail, taking you through the branches to sub-categories.

“Let’s say I need to overhaul the valves of my subsea manifold system,” explains Sverre.

“On my computer, I click on the overall installation. I follow the branch to the piping system, then to the valves section where I find my specific valve and all the documents relating to it.”

TruePLM uses version control to track changes in documents and keep the original while saving updated versions, so everyone knows who did what when – very useful when a complex machine or installation is in the design phase and engineers from different companies grapple to trace the latest valid drawings.

The transfer of TruePLM to oil and gas is one of many success stories where non-space companies benefit from innovations originally developed for space.

“TruePLM was a perfect candidate to spin off,” says Frank M. Salzgeber, Head of ESA’s Technology Transfer Programme Office. To help transfers, the office has setup the Technology Transfer Network of brokers in 13 European countries.

“We’re a bit like a matchmaking service. We help non-space businesses to find cutting-edge space technology they might never have thought of using. Our space programmes present an endless supply of opportunities.”

“Certainly for Jotne, transferring the technology developed for ESA to non-space applications has set us on an exciting journey with new business prospects,” says Kjell Bengtsson.

“And the great news is that our customers in aeronautics and defense are already interested in using TruePLM.”

So what’s next for this smart piece of space software? The automotive industry? Food processing plants? Electronics and gaming? It’s certainly one to keep an eye on. Soon this canny system developed for ESA to keep track of its spacecraft might find its way into all kinds of non-space activities – and even our everyday lives.