Space sensor helps produce ‘greener’ glass

What has making glass in common with space exploration? The special technology to measure oxygen atoms outside space vehicles is now being used in the glass industry to produce super-efficient energy-saving windows.

With modern architecture featuring large glass facades, it has become important to improve the insulating characteristics of glass.

The windows must protect the interior against heat loss during cold weather and against overheating on warm summer days.

“By using sensor technology from space this has been possible,” explained Frank Hammer, founding member of the German company ESCUBE, which developed the special instrument initially for spaceflight.

Through MST Aerospace, the German technology broker of ESA’s Technology Transfer Programme, contacts were established with a glass manufacturer.

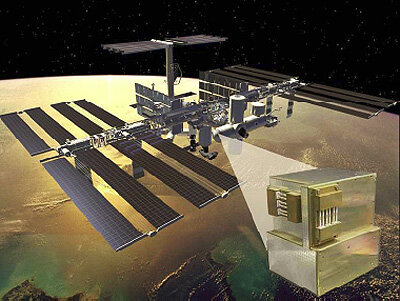

Today, the sensor is mounted outside the International Space Station and used in a German glass factory.

“For space, the sensor was developed to measure atomic oxygen, known for its erosion effect and for degrading optical surfaces,” said Mr Hammer.

“In the glass industry the technology is now used to control the industrial glass-coating process to obtain improved insulating properties.”

The complex coating procedure requires reliable and precise monitoring to control the process.

“The gas sensor developed to handle the harsh space environment turned out to be the right solution to handle the difficult glass-production conditions of high temperatures and reactive gasses,” added Mr Hammer.

Started with reentry space vehicles

It all started back in 1993 when ESA asked the University of Stuttgart to develop ceramic gas sensors to measure the atomic-oxygen levels around reentry craft under extreme test conditions.

Further miniaturised by the University of Dresden, the Flux-(Phi)-Probe-Experiments (FIPEX) were flown on several space experiments, including the Russian Inflatable Reentry and Descent Technology research capsule.

In 2008 FIPEX was launched on the STS-122 Shuttle mission and mounted outside ESA’s Columbus laboratory module on the International Space Station.

“Part of the European Technology Exposure Facility outside Columbus, FIPEX helps to understand the atmospheric environment in low orbit by measuring the highly aggressive corrosive atomic oxygen around the Station,” explained Martin Zell, Head of ESA’s Research Operations Department.

“The people from the University of Dresden and ESCUBE developed a very efficient sensor fulfilling our requirements for space, with reduced size, weight and power consumption.

“I can see the same sensor technology could provide advantages in many applications on Earth as well, compared to existing similar sensors.”

Owing to its miniaturisation, low power consumption and other technical benefits, considerable interest arose from industry for terrestrial use of the sensors in medicine, environmental research and vacuum applications.

ESCUBE was set up in 1999 to introduce this innovative space technology in non-space markets.

Based on FIPEX and the specific glass-industry requirements, ESCUBE developed the new VacuSen sensor for vacuum and plasma applications, providing easy, low-cost, time-resolving process control for industrial processes such as a magnetron reactive gas sputter plant for float-glass coating.

“The goal was to optimise the coating process and enhance the quality of the coating,” added Mr Hammer.

Space technology helped produce ecological glass products

Peter Hennes from ESCUBE partner company iSATT added, “With ESCUBE’s sensor it is today possible to offer new types of glass."

"Their surfaces not only take into account economic and ecological criteria but also fulfil aesthetic criteria, saving energy by the low overall heat transfer coefficients.

“With the new coating the overall heat transfer coefficients have been reduced to about a third of what they were in the 1980s, while maintaining light transmittance at 80%.

“The light passing through is almost the same as standard glass, but the heat loss during winter and the heat gain during summer have been reduced significantly.”

ESA’s Technology Transfer Programme Office (TTPO)

The TTPO’s main mission is to facilitate the use of space technology and space systems for non-space applications and to demonstrate the benefit of the European space programme to European citizens.

The office is responsible for defining the overall approach and strategy for the transfer of space technologies, including the incubation of start-up companies and their funding. For more information, please contact:

ESA’s Technology Transfer Programme Office

European Space Agency

Keplerlaan 1

2200 AG, Noordwijk

The Netherlands

Tel: +31 71 565 6208

Email: ttp@esa.int