Mechanical Data Handling System

What are they for?

The Mechanical Data Handling system provides a set of state-of-the-art tools to monitor and analyse the mechanical behaviour of satellites and their payloads during vibration, acoustic and shock tests.

What kind of testing does it support?

The system gathers data for vibration, acoustic and shock tests, as performed by the electrodynamic shakers, HYDRA and Large European Acoustic Facility.

What are its features?

The system allows:

- Conditioning/filtering of transducer signals

- On-line acquisition of the time domain signal

- Online standard data reduction for sine sweep and random excitation

- Data presentation and reporting

- Data organisation and archiving

Data exchange with external systems

The system enables engineers to connect with all kinds of sensors such as piezoelectric sensors, injection control point sensors (ICP), strain gauges, load cells and voltage monitoring inputs. It is also compatible with transducer electronic data sheet (TEDS) technology.

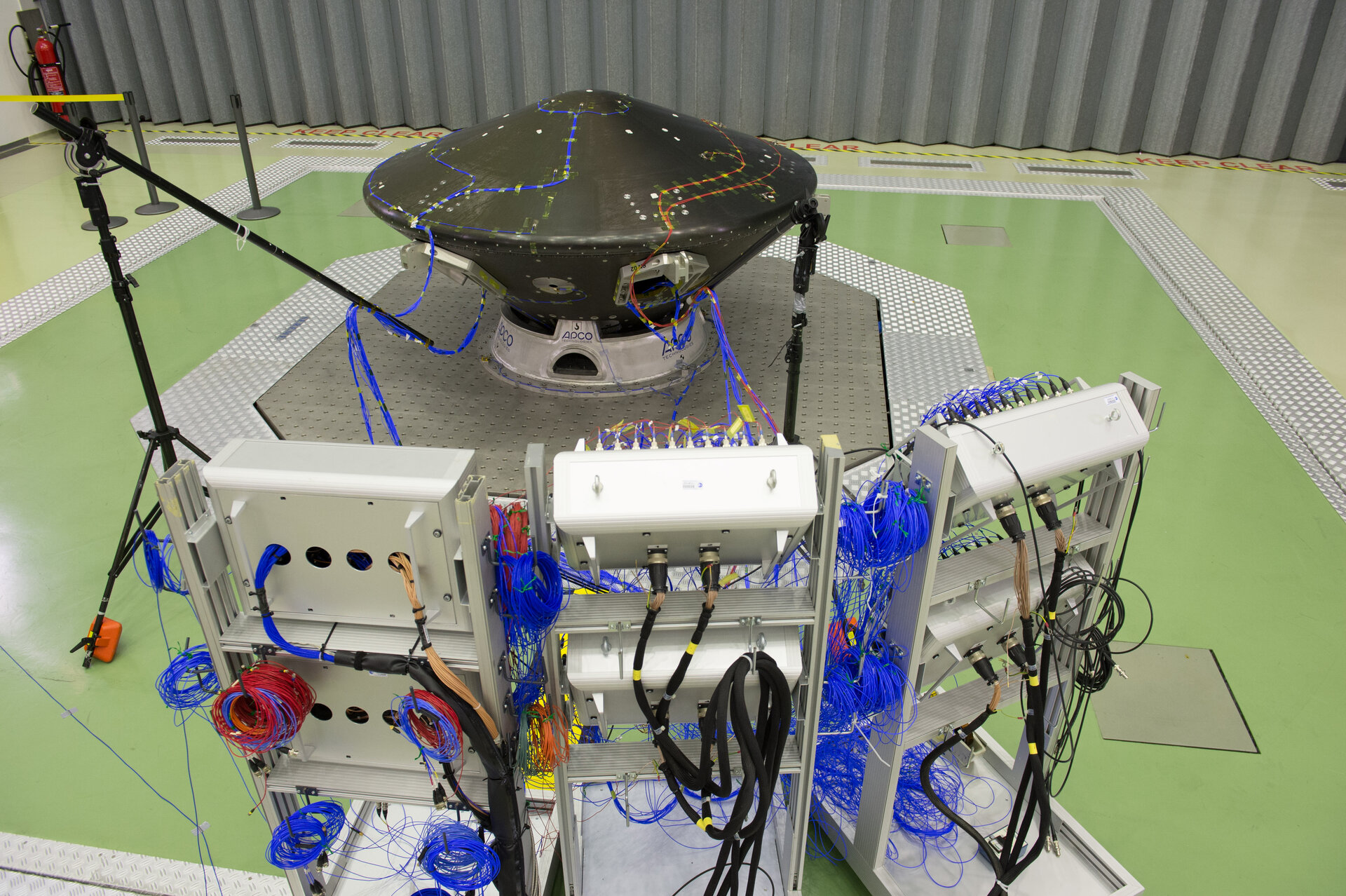

Four moveable cabinets are available able to acquire 128 channels each. They can be used individually or combined to record 512 synchronised channels. Engineers can operate them locally or remotely from a master computer station. The local rack containing the conditioning and digitisation modules are close to the specimen (typically 15 metres) to improve the signal-to-noise ratio. Moveable patch panels are available to connect all sensors and check them while the satellite is still under preparation. These patch panels also allow a quick re-configuration between the different tests.

The standard online data reduction provides:

- Sine – frequency spectra with up to five estimators RMS, harmonic, peak, average and total harmonic distortion; frequency transfer function relative to a common reference channel

- Random - power spectra density; power frequency functions

Additional software is available to make special offline processing of time domain responses (transient time, sine, random, acoustic…).

As standard, engineers can visualise and analyse data using either LMS test Lab system or DynaWorks. The data can be imported to any system able to read files in UFF58. Easy exchange of data with Excel is supported.

All 512 channel frequency responses are exported in electronic format and plotted less than 20 minutes after the end of the test.

What benefits does it deliver?

The Mechanical Data Handling System haa increased the flexibility of ESTEC Test Centre operations, with mobile processing stations able to be moved around the site as needed. This allows an increased frequency of mechanical test activities.

Its facilities also allow rapid data delivery to customers: after a large test, data can be handed over on a USB stick in about 30 minutes for more than 500 channels, without requiring any post-processing. As a fully online system all information is integrated, including configuration, conditioning and data acquisition.

For more information

Please contact Gaetan Piret, ESTEC Test Centre Manager.

Gaetan.Piret @ esa.int