Heart of glass

What’s the best way to keep track of medicines or luxury goods? Just give them a number, of course. But what if the item you want to keep your eye on is made of glass?

Thanks to a new laser technology developed for space, a Belgian start-up company called Trackinside is now able to inscribe numbers in glass without cracking, heating or leaving any external marks on the glass.

“It’s the only technology that can mark glass without damaging it,” said Jean Michel Mestrez, Trackinside Managing Director. The low-impact laser inscribes serial numbers inside, rather than on the surface, of the glass used in medical syringes, perfume vials or drinks bottles.

The laser technology was initially developed in Belgium at the Centre Spatial de Liège (CSL), working with the LASEA CSL-spinoff group, which was initially devoted to developing cleaning processes using lasers. CSL is a partner of the Belgian Space Technology Platform, ESA’s national technology transfer broker coordinated by Créaction International.

There, it was created for things like etching the surfaces of lenses and mirrors that would then be used in space telescopes and measuring equipment. The challenges of operating such sensitive instruments in space conditions meant that CSL needed to create a high-tech tool to produce the best possible lenses and mirrors.

“Just like you use a pencil to make corrections when you write, the laser is the tool we use to correct the mirror,” explained Joseph Bernier, who is in charge of Technology Transfer & Industrial Cooperation at CSL.

While it may seem like a far cry from recording the astronomy of space events to preventing counterfeiting here on Earth, CSL’s new laser technology “is a basis of the Trackinside technology,” said Mr Bernier.

The ‘femtosecond laser’ works much like the laser used in eye surgery, where it beams energy through the surface of the eye to make incisions deep below.

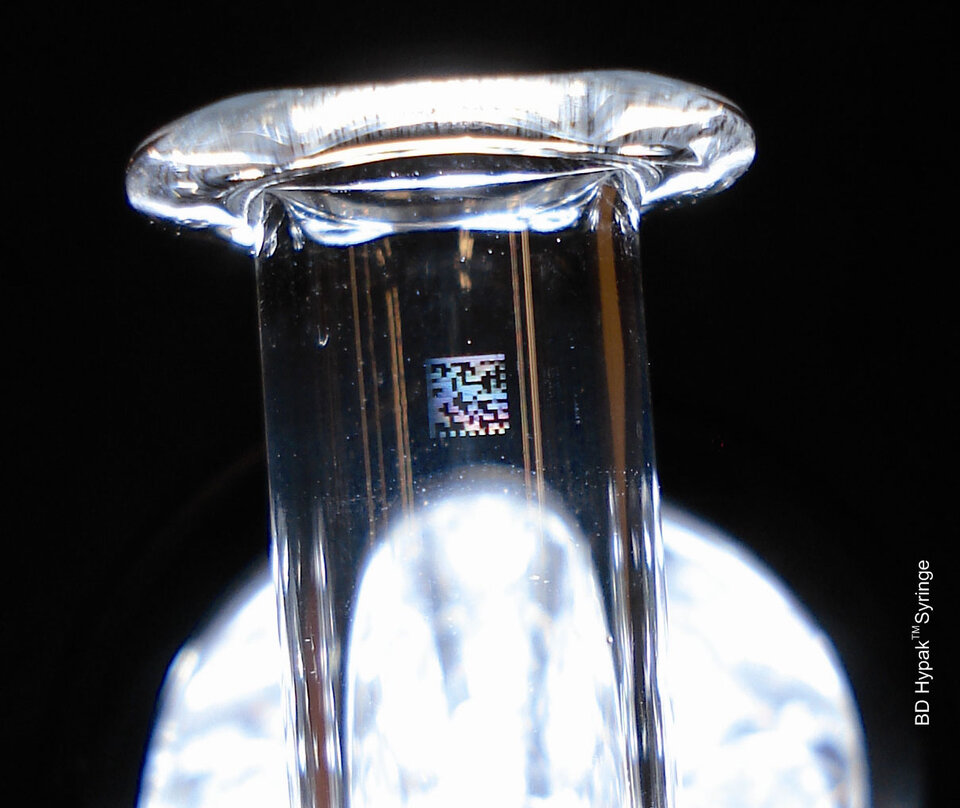

The Trackinside laser is calibrated for glass, sending beams of energy through the surface of, say, a syringe.

The beams then ‘land’ at a focal point inside the glass, marking the material there. Serial numbers or other identification are inscribed using very brief pulses.

“Because the duration of the pulse is so short, and uses very low energy, there’s no thermal effect,” said Mr Mestrez. This means the laser does not overheat the glass the way typical lasers would. Because it is so low-impact, it does not create micro cracks or any other damage in the delicate material.

For the past year, the company has been busy helping international pharmaceutical companies keep track of their wares in a way never before possible. In the past, medicines would be marked only in batches, not syringe by syringe. But new EU regulations are leading more and more pharmaceutical companies to seek out this kind of ‘down to the last drop’ tracking capacity.

“Labelling each syringe has other benefits, too,” said Mr Mestrez. “With this technology, you can track medicine from the point of production.” This can greatly reduce the risk of mix-ups.

“If you have a number labelled directly after filling up the syringe, you can trace that syringe all the way along, from production to use to disposal.”

Reimbursement schemes, in which patients are paid for the medication they use, are also easier to implement and monitor when patients can return numbered syringes.

While pharmaceutical companies make up the bulk of Trackinside’s business for now, other clients include makers of perfume and cosmetics. For luxury goods, this new type of numbering is useful not only to track products, but also to protect high-profile brands.

“With pharmaceuticals, it’s about traceability. With perfume, cosmetics and luxury beverages, it’s about anti-counterfeiting,” said Mr Mestrez.

One of the real benefits of his company’s technology for companies selling luxury goods, according to Mr Mestrez, is that labelling individual bottles gives producers the ability to track distribution channels and grey market activities.

For example, if a beverage is produced for the Asian market, but the bottle shows up in Europe or Africa, the maker can see that a grey market is operating.

The car industry is also a potential client base, particularly in Germany, where according to law every piece of a vehicle must be recycled.

But the possibilities are almost endless. With this technology, companies can keep track of all kinds of previously untraceable products.

One day, individuals might want to take advantage of it, say, by writing your name in your favourite pair of glass slippers should you accidentally leave one behind at the ball in your haste to get home before midnight.

ESA’s Technology Transfer Programme Office (TTPO)

The TTPO’s main mission is to facilitate the use of space technology and space systems for non-space applications and to demonstrate the benefit of the European space programme to European citizens.

The office is responsible for defining the overall approach and strategy for the transfer of space technologies, including the incubation of start-up companies and their funding. For more information, please contact:

ESA’s Technology Transfer Programme Office

European Space Agency

Keplerlaan 1

2200 AG, Noordwijk

The Netherlands

Tel: +31 71 565 6208

Email: ttp@esa.int