Wide-eyed Proba-V will track global vegetation daily

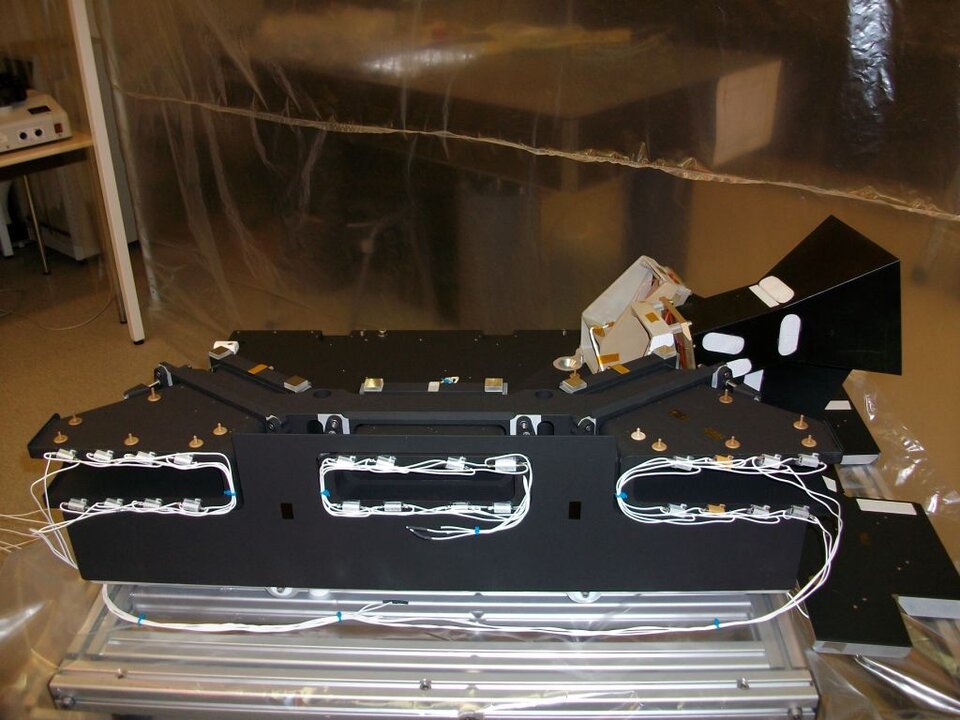

The small but powerful payload of ESA’s Proba-V mission can fit onto a single laboratory table for testing. But when it reaches orbit, this compact sensor will deliver a daily overview of virtually all vegetation growth across Earth.

Daily global monitoring is an ambitious enough goal for a full-sized mission, but Proba is ESA’s smallest satellite platform – with an overall volume of less than a cubic metre. Engineers had to be innovative in the way they designed the instrument to make this payload feasible; the result has been evaluated at ESA’s ESTEC space technology centre in the Netherlands.

A test version of the Proba-V imager –the Structural and Thermal Model (STM) – has been subjected to a combination of hard vacuum and temperature extremes in ESTEC’s Mechanical Systems Laboratory, simulating conditions it will face in space.

So far, the Proba series has focused on the demonstration of new technologies in space: Proba-1 has been in orbit since 2001, with Proba-2 joining it last November and Proba-3 in development, aimed at investigating formation-flying.

Proba-V is a new departure because, on top of its technology demonstration, it will provide data to an existing users of the Spot-5 Vegetation instrument.

“Proba-V’s Vegetation payload will need to be operational on top of its experimental nature,” explained Karim Mellab, Proba-V Project Manager. “There is going to be a large number of people in need of the data it will provide in order to go on doing their jobs.”

Race against time to deliver data continuity

For the past 12 years, the Vegetation sensors on CNES’ Spot-4 and Spot-5 satellites have been gathering data on global vegetation growth and land cover changes. With an extremely wide 2250 km multispectral viewing swath and ability to revisit all locations on Earth on a daily basis, Vegetation has found many uses in environmental monitoring and climate-change studies. Its wide-area views have also supported disaster relief.

But France’s planned follow-on satellites, the Pleiades, will not have room to carry further Vegetation sensors. Instead, ESA and the Belgian Federal Science Policy Office (Belspo) began investigating the feasibility of flying a cut-down version of the instrument to continue delivering data to its users.

“One of our main objectives is to get the new sensor in orbit by mid-2012,” explained Mr Mellab. “This will give us overlap with Spot-5’s Vegetation sensor, allowing us to calibrate the new instrument.

“That puts the emphasis on schedule – we have to be ready on time. And that explains why the Proba platform was selected to host it, because its flight heritage allowing a large reuse of the satellite system and subsystems design.”

Shrinking the sensor

The Vegetation sensor still needed a complete re-engineering to fit onto a Proba platform, explained Luca Maresi, overseeing the payload design: “Vegetation is one of the smallest payloads aboard Spot-5, so the idea is to take it and fly it by itself. But Spot-5 is the size of a lorry, while the sofa-sized Vegetation weighs more than 130 kg.”

Vegetation had to be reduced in volume by a factor of ten, and ESA also sought improved performance, including increasing its spatial and spectral resolution. “It was big; it had to be small,” added Mr Mellab. “To achieve this, we had to take advantage of all advances in technology since the instrument was first produced in the early 1990s.”

Back then, only a combination of heavy glass lenses could yield Vegetation’s uniquely wide 105° field of view, and separate lenses were required for its four spectral bands. Its sensitive short-wave infrared detectors also demanded a heavy, power-hungry cooling system.

The drive to lose mass led designers to swap glass for lighter aluminium mirrors, which have the additional advantage of observing across all spectral bands without the need for duplication. The challenge was to produce aluminium mirrors with just the right ‘aspheric’ shape needed for Vegetation’s wide viewing angle.

Reducing the size of mirrors needed, the imager was subdivided into three separate telescopes with overlapping views of 34° each, although even then its mirrors required a manufacturing technique of unprecedented precision known as ‘single-point diamond turning.’

A prototype telescope was developed last year through ESA’s General Support Technology Programme (GSTP), serving to develop hardware to flight readiness. Belgian companies are leading the project, with QinetiQ Space Belgium serving as the mission’s prime contractor and OIP Sensor Systems subcontracted to develop the Proba-V imager.

New design put to the test

At ESTEC’s Mechanical Systems Laboratory, OIP personnel oversaw thermal-vacuum testing of the Vegetation STM. Temperature-measuring thermocouples were attached before it was covered with multi-layer insulation (MLI) and placed inside a temperature-controlled box; it was then placed in a vacuum chamber. The aim was to duplicate orbital conditions, including the abrupt passage from light to darkness as the satellite passes behind Earth.

“We are checking the instrument temperature stays within set limits,” said Jorg Versluys of OIP. “Because the three telescopes have overlapping views, any temperature-driven mechanical deformation could put them out of alignment.”

With its mass and power requirements strictly limited, the imager lacks active thermal control systems such as radiators or heaters. Instead, the instrument is kept as isolated as possible, using a dozen MLI layers and sunscreening baffles with poorly-conducting titanium isolators attaching it to the satellite body.

The entire imager, including its base plate, is made of the same aluminium as the telescope mirrors, meaning components will expand and contract together. As a result, the thermo-mechanical deformations are further reduced.

Later this year, the Vegetation STM will be used for vibration and structural testing, both individually and in conjunction with a Proba satellite test model, with the completed flight models undergoing the same testing in 2011 to meet the mission’s mid-2012 deadline.

Focus on quality

“The project is proceeding on an ‘end-to-end’ basis,” explained Mr Mellab. “This means we are preparing everything, not only the space and ground segment but also the user segment – the infrastructure needed to transport the data from orbit to its end users.

“As part of this, a System Performance Simulator allows us to estimate the quality of the data delivered to users as the engineering process proceeds. If necessary, we can go back and retrofit the mission design to enhance quality.”

As well as QinetiQ and OIP, the Proba-V consortium includes many additional companies: Belgium-based VITO is responsible for the user segment; Spacebel is developing onboard software; Luxembourg-based Eurocomposite is working on the satellite’s mechanical structure; Canada’s NGC is contributing attitude control systems.

In addition, AMOS (BE) is producing the telescopes, XenICs (BE) is developing the infrared detector, and CSL (BE) is in charge of the calibration. DSI (DE) is developing the instrument Data Handling Unit and Thales Alenia Space (BE) is producing the Power Supply Unit of the instrument. Finally, E2V (FR) is delivering the visual detectors.