Giant robot helps prevent landslides

Fighting landslides is dangerous work, but help from space is on its way. Recent testing in Italy has shown that the four-tonne Roboclimber can secure slopes without endangering human lives, thanks to innovations from Europe's space programmes.

"It was amazing to see how easily this huge robot managed to operate on a very steep slope to secure a rocky mountain wall,” said Guglielmo Berlasso, Director of the Civil Protection Office in the Friuli-Venezia Giulia region in Italy, where the demonstration took place.

Landslides are a big problem in Italy. More than 400 take place each year causing an estimated €1200 million of damage and often deaths. In the 20th century 5939 people were declared dead or missing due to landslides.

Alfredo Sandovar from the European Commission was also present at the Roboclimber demonstration and expressed his great satisfaction with the results. “We are aware of the big dimension of this problem which is why we decided to finance this project,” he said.

Roboclimber passes its test

The setting for the first field demonstration of Roboclimber, one of the largest robots in the world, was the beautiful valley of Alta Val Torre, 25 km north of Udine in the Friuli-Venezia Giulia region of Italy. The mayor of Lusevera selected a near-vertical 30-metrer high rocky wall – similar to a possible landslide location – to enable the Roboclimber to be tested to the full.

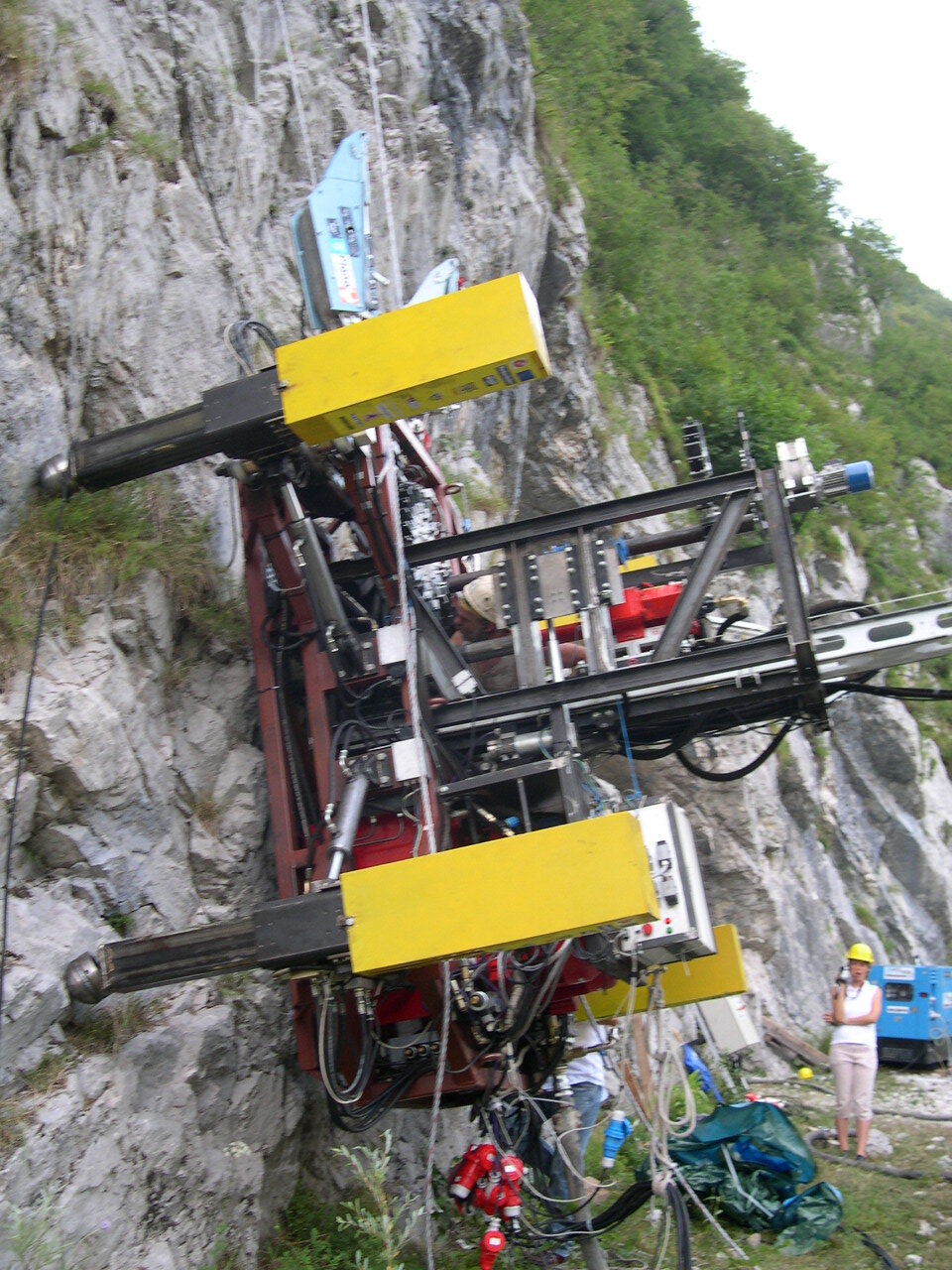

The heavy Roboclimber arrived by truck and was installed by ICOP, the construction company that initially proposed the project and the prime contractor for the development. The robot was mounted on the mountain wall and held in place by two wires fixed at the top of the wall. Roberto Zannini from Teve, one of the inventors of the system together with the PMARlab of the University of Genova, supervised the tests designed to demonstrate the agility and efficiency of the robot.

Equipped with a special Comacchio 28 kW drilling machine with an impressive 2400 Newton metre torque, about 80 times stronger than a typical hand-held home electric drill, within minutes Roboclimber had drilled a more than 10-metre deep hole into the rock-solid wall, the first step in the typical procedure used to stabilize walls at risk of landslides.

The drilling was controlled remotely from a safe distance with a computer supplied by the Belgium company SAS and a wireless link. The technique was originally developed to control robots in space. An onboard web-camera enabled the operator to manoeuvre it into the correct position without difficulty, execute the drilling and insert the rods. Once each rod had been inserted the operator moved the robot to the next position, repeating the sequence of drilling and inserting rods. The speed at which the robot inserted rods and secured the wall was very impressive and much faster than the conventional methods used at present.

Roboclimber can drill holes 20 meters long and with a diameter of up to 76 mm, in any rock and on any gradient. An innovative rod-house and robotic manipulator allows fully automatic loading and unloading of drilling rods.

Reduce human risk and save money

At present consolidating risky slopes entails setting up high scaffolding and manually inserting stabilizing rods using hand held tools and drills; a very dangerous job as there is the constant risk of soil or rocks falling and hurting the operators.

"The saving in cost and time depends on the type of wall, but can be huge," says Giorgio Pezzuto from D'Appolonia, which played a key role in getting together the right expertise and relevant space technologies.

Enzo Rizzi, Roboclimber project coordinator from ICOP, clarifies, "Assuming a typical landslide front of 5000 square metres requiring 5000 metres of deep drilling, we estimate that the Roboclimber system can save €75 000. In terms of time, the savings are huge: it takes a few hours to install Roboclimber while setting up a scaffold can take days and even weeks in critical situations."

"But the most important factor is that with Roboclimber we can secure steep rocky walls without risking human health and lives. We can do it faster, more efficiently and yet much safer," he emphasises.

Using space technology

Roboclimber has been constructed using expertise and technology from Europe's space programmes. Weighing 3800 kg, with four legs and with a square base of 2 metres by 2.5 metres, Roboclimber is one of the largest robots in the world, yet still very agile and easily controllable. The on-board control system includes algorithms based upon ESA advanced methodology for controlling satellites in space.

"The participants are now evaluating the best approach to getting this innovation on the market," says Giorgio Pezzuto. "A new start-up company will guarantee the continuity and availability of our expertise. We intend to provide other services using Roboclimber technology as well as market the Roboclimber platform."

Says Pierre Brisson, head of ESA's Technology Transfer and Promotion Office, "the experience gained from our many transfers shows that the use of innovative technologies from our space programmes often leads not only to improved solutions but also to new jobs in Europe. In this case our expertise and high-tech from space provide economical gain and better working conditions and safety: the best combination we could wish for."