Open wide: dentists get help from space

Dentists and their patients will soon benefit from a tiny new high-resolution X-ray camera. A Swedish company has adapted an advanced technique used for miniaturising space hardware to make a visit to the dentist a little more comfortable.

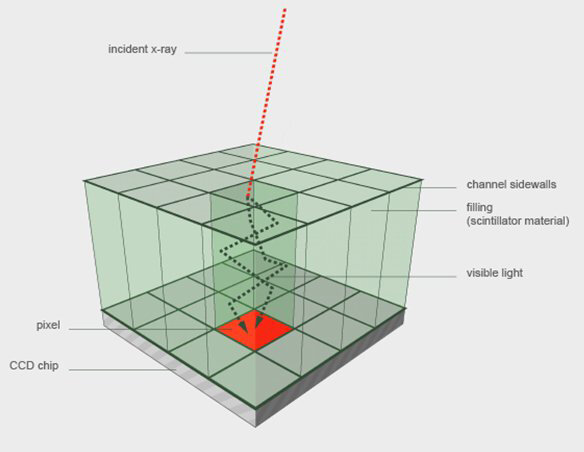

The camera takes X-ray pictures that are dramatically more detailed and with higher contrast than the conventional X-ray machines widely used by dentists today. The heart of the camera is a tiny ‘structured scintillator’ device that converts X-rays to visible light.

The camera was designed by the Scint-X company and the key element – the scintillator – was built by Swedish company Nanospace, drawing on their experience of producing space systems.

In fact, the production technology has already been used by Nanospace to cut the world's smallest rocket motor out of silicon wafers.

"Our scintillator uses a specially structured silicon substrate and with this unique and patented manufacturing technique we can obtain substantially higher resolution than what is on the market today," explains Per Wiklund of Scint-X.

Another advantage is that the X-ray unit inserted into the patient’s mouth is much thinner than today’s models, making the procedure more comfortable.

Space production paved the way

Using a scintillator to convert X-rays into visible light is well established, but so far the low resolution has been a limitation.

The breakthrough came when Scint-X produced the scintillator in the new structured silicon and asked Nanospace to build it in their high-precision ‘micro-electro-mechanical system’ (MEMS) facility.

“The investment in our special machine [to produce MEMS] was entirely driven by the demand for capacity and quality in our production for space projects,” says Tor-Arne Grönland, CEO of Nanospace.

"Later, a number of non-space companies and research groups, such as Scint-X, have taken advantage of the processes and the capacity we now have.”

Nanospace used MEMS to build the miniature rocket motor flying on Prisma, a Swedish technology demonstration satellite launched in June 2010. Measuring only 51mm by 43.5mm, it is a complete micropropulsion system for precision control of a small satellite.

Miniaturised solutions for space

Nanospace is working with ESA on the use of MEMS to provide miniaturised solutions for many of the fluid-handling components required in satellite propulsion systems.

“ESA funded the research and development of the MEMS cold-gas thrusters that is now performing its first flight on Prisma,” says Fabien Filhol from ESA’s Product Assurance and Safety Department.

“Now ESA is exploring with Nanospace the limits of this emerging MEMS-based micropropulsion technology for high-accuracy propulsion applications.”

“In addition, another ESA project with Nanospace is exploring a different application of MEMS technology for satellite propulsion systems. It aims to develop a satellite-propellant gauging system that would eventually reduce the operational uncertainty for telecommunication satellites’ end-of-life, resulting in extended revenues for the satellite owner."

Scint-X’s spin-off returns to space

Right: Scint-X X-ray

Better X-rays for use in dentistry is just one application for this new technology. Scint-X’s innovative technology can also make a significant difference in materials research and inspection of components.

This approach also has potential for use in space. After successfully testing a prototype X-ray system that contains the new scintillator, the Swedish Space Corporation is planning to use Scint-X’s camera for advanced materials studies aboard a rocket that is planned to be launched in May 2011 by ESA.

“Our camera provides a resolution that is better than five microns and will be used to study the melting and solidification of metals when producing exotic materials in weightlessness," explains Wiklund.

“The synergy between space and non-space research and development, as in the case of Scint-X, illustrates the potential of technology transfer,” explains Frank M. Salzgeber, Head of ESA’s Technology Transfer Programme Office.

“An advanced production technology set for space systems makes the development possible for a non-space orthodontic camera, which then can result in an innovative instrument for research in space.”

ESA’s Technology Transfer Programme Office

The main mission of the TTPO is to facilitate the use of space technology and space systems for non-space applications and to demonstrate the benefit of the European space programme to European citizens. The office is responsible for defining the overall approach and strategy for the transfer of space technologies, including the incubation of start-up companies and their funding. For more information, please contact:

ESA’s Technology Transfer Programme Office

European Space Agency

Keplerlaan 1

2200 AG, Noordwijk ZH

The Netherlands

Tel: +31 71 565 6208

Email: ttp@esa.int