Blackwave: Innovative production of carbon fiber component

ESA Business Incubation Centre Bavaria start-up Blackwave has developed a highly automated process for the cost-efficient production of complex carbon fiber components. Meet Blackwave at ESA's Start-ups Zone powered by ESA space solutions at IAC 2018.

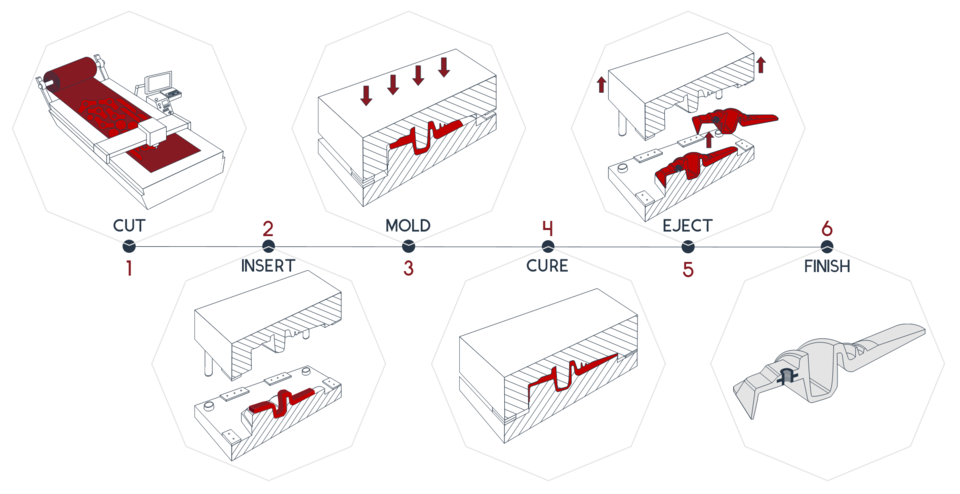

The technology used is the Carbon Sheet Molding Compound (C-SMC), which is a compression molding process of a compound mixed of chopped carbon fiber and thermoset plastics.

Forced by high pressure and heat, the material flows in its final shape.

This process solves many problems of conventional CFRP manufacturing methods, which can be mainly sorted into two groups: Production costs and design possibilities.

The process can be fully automated, which makes it stable and affordable for high production volumes. The cycle times for the molding process itself are under 3 minutes and the preforming effort is drastically reduced.

Cost-efficient and sustainable

Beneficial side effect of the simplified plies for preforming and the net-shape geometries is that the waste is severely reduced. This is not only very cost efficient, but also very sustainable. Another ecological benefit is that there are nearly no consumables such as vacuum bagging films or hoses for resin transfer, as they are common in other production methods. This leads to an overall waste reduction of 95%. Furthermore, SMC is one of the most promising approaches to process recycled fibers.

Looking at the design possibilities there is much more freedom than using conventional, semi-finished textile products such as fabrics or tapes, which are bounded to more simple and flat geometries.

The flow of the compound enables complex features like ribs, stiffeners and changes in wall thickness. Moreover, manufacturing of blind holes and fits as well as co-molding of metallic inserts for threads is easy to integrate into the process, which has both mechanical and economic advantages.

Utilizing the C-SMC technology, Blackwave is able to offer the complete value chain from first concept, technology appropriate drafting, detailed component design to series manufacturing in our own plant.

Hosted at ESA BIC Bavaria

Blackwave is hosted at ESA´s Business Incubation Centre the company got access to aerospace laboratories and testing facilities.

“This helped us to test components and validate our simulations,” said Bastian Behrens from Blackware.

“With the help of our close-kit network of trusted partners and advisors we are able to understand and meet quality standards of the automotive, aerospace and sporting goods industry.”

With excellent design possibilities and specific mechanical properties greater than aerospace grade aluminum, Blackwave serves a niche in the CFRP market with huge potential. There is a vast range of potential applications and customers in the aerospace, aviation, automotive and sporting goods sector. With its unique and aesthetic appearance C-SMC is as well attractive to lifestyle and luxury applications.

World's largest ecosystem for space-related entrepreneurship

ESA’s Technology Transfer and Business Incubation Programme Office (TTPO) operates the ‘ESA space solutions’ network of Business Incubation Centres (ESA BICs) and Technology Transfer Brokers offering complete access to all aspects of space-related innovation, technology and intellectual properties and is a gateway to ESA and European space research and developments.

Today, there are 20 ESA BICs in 17 European countries – Austria, Belgium, Czech Republic, Estonia, Finland, France, Germany, Hungary, Ireland, Italy, Norway, Portugal, Spain, Sweden, Switzerland, the Netherlands and UK – forming the largest ecosystem in the world for space-related entrepreneurship.

Over 650 start-ups have been fostered and another 150 new start-ups are taken in yearly at ESA BICs to be supported under the two-years business development boosting programme.

Visit “Start-ups Zone powered by ESA space solutions”

Meet all the start-ups from 1 October until 5 October at the dedicated Start-ups Zone powered by ESA space solutions at IAC 2018 area at IAC 2018.

The Blackwave entrepreneurs will be at the Start-ups Zone at IAC 2018 from 3 October noon until 5 October, and be pitching their business 4 October.