ESA ESTEC expertise and facilities assist COROT project

The engineering know-how and facilities at ESA-ESTEC have been crucial to the successful design, assembly and alignment of the COROT telescope baffle. Engineers from ESA’s Directorate of Technical and Quality Management have worked alongside Belgian companies, establishing a team that successfully designed, manufactured and tested the telescope’s baffle and shutter.

The COROT mission and its telescope, COROTEL

COROT is a French led mission being developed by the French national space agency (Centre National d'Etudes Spatiales – CNES) in association with several research laboratories and with the participation of a number of European partners, among them ESA and Centre Spatial de Liège (CSL).

COROT (Convection Rotation and planetary Transits) mission focus on two scientific goals: stellar seismology (the detection and measurement of stellar oscillations) and searching for planets orbiting stars other than the Sun.

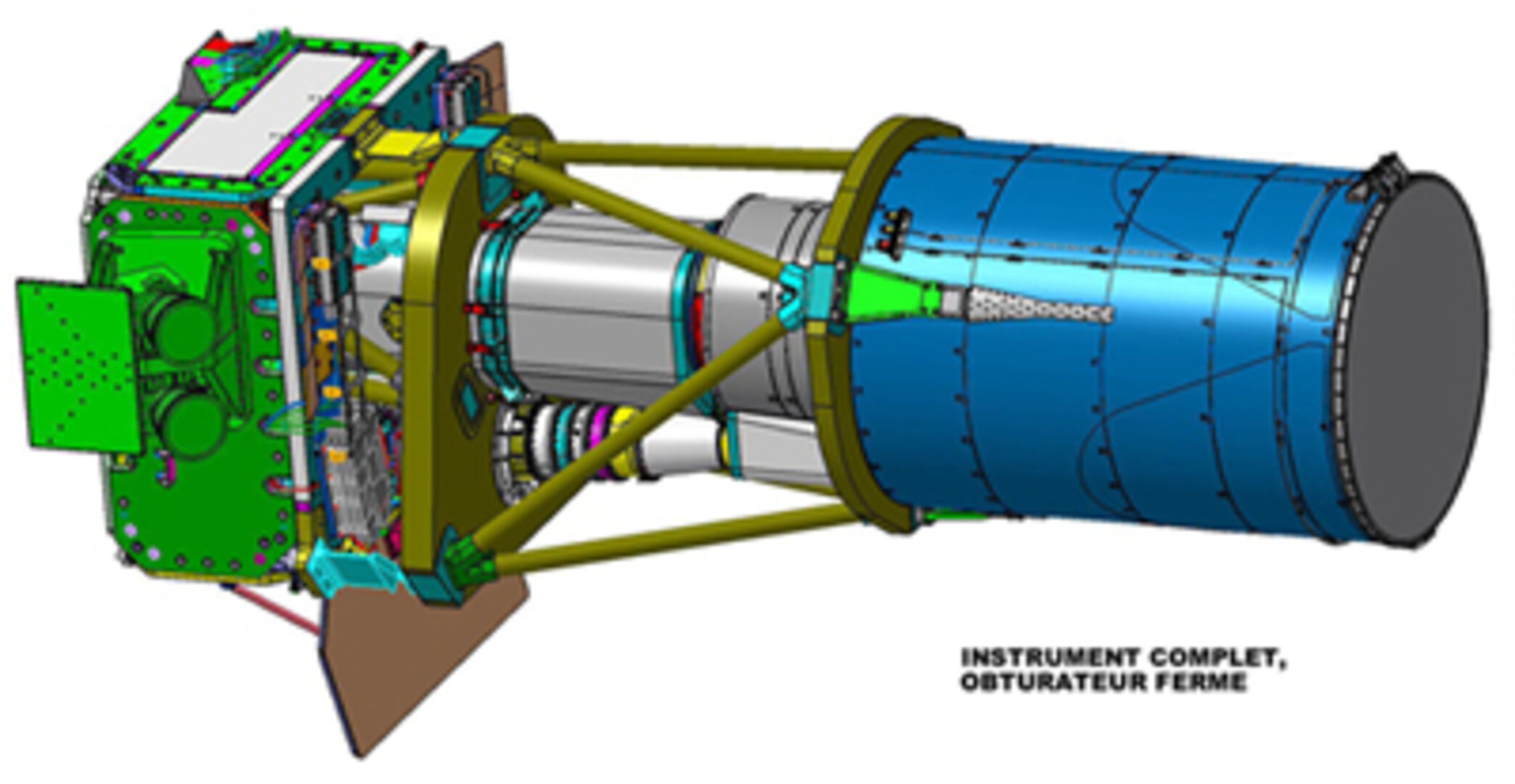

To measure variations in stellar flux with a high degree of accuracy, the optical instrument incorporates the telescope COROTEL. To perform its task, COROTEL has to be very well protected against stray light (light not coming directly from the star under observation, but from other sources, principally Sun and Earth) and must remain mechanically very stable over long periods of time.

The mission objectives require a telescope with a straylight rejection ratio of around 1012, which means that the straylight must be one million million times weaker than the light from the distant star being observed. This is the highest rejection ratio ever required for a space telescope of this class. Therefore, to satisfy the requirement, the telescope design includes a high performance baffle to shield the entrance of straylight within the optical system.

How ESTEC contributed to the development of the COROT baffle

ESTEC contributed to the development of the COROT baffle through the PROgramme de Développement d'EXperiences scientifiques (PRODEX), an ESA optional scientific programme established in 1986 to provide funding for the industrial development of scientific instruments or experiments. The support was provided to the Centre Spatial de Liège (CSL), which is the institute responsible for the procurement and environmental testing of the baffle and shutter.

In addition to the management of the industrial contract, awarded to Verhaert Space (Belgium), ESA engineers have contributed to the development, design and manufacture of the baffle and shutter assembly, supporting Verhaert engineers in the following technical areas: structure analysis and mechanical testing, mechanisms, integration and assembly, and material quality engineering.

Further information about ESA’s contribution in each of these areas can be found by following the links in the right hand menu (COROT technical activities).

A satisfactory result

The COROT baffle has been successfully designed, manufactured and tested thanks to the collaboration between the European project partners, Verhaert, CSL, CNES and ESA. The cooperation between all parties has resulted in successful qualification of the baffle in the CSL test facilities.

According to Jean-Marc Defise, Head of Space Instrumentation at CSL: “The mechanical requirements of the COROT baffle were extremely rigorous and they quickly became the main difficulty to be overcome during the project. Several experts from ESA reinforced the team in the areas of acoustic vibrations, mechanisms, mechanical design, materials and metrology. The technical support, knowledge and experience of the ESA engineers greatly benefited the development of the flight hardware, assisting greatly with the successful design, manufacturing and testing of the COROT baffle."

The benefit of the cooperation has also been acknowledged by Jo Bermyn, Business Unit Manager, Satellites and Platforms at Verhaert Space: “The close cooperation with ESTEC engineers has proved to be very fruitful and efficient. In particular the combination of technical competence with unique facilities, specifically the Metrology Laboratory, was of fundamental importance to performing the assembly and integration of the COROT baffle, bringing the work to a successful conclusion.”

This project has demonstrated again how the competence and the knowledge of ESA staff, combined with the ESTEC technical facilities, can benefit space hardware development among the European Partners; National Agencies, European Universities and Industries.

For more information please contact:

Jose Gavira Izquierdo, PRODEX Technical Manager

![]()

Francesco Ratti, Mechanical Design Engineer

![]()