2006: a challenging year for Jules Verne

At ESA's test facilities in the Netherlands, technicians have been working hard on Jules Verne - Europe’s first Automated Transfer Vehicle (ATV) - to replace all 48 valve-actuators in the spaceship’s propulsion system. This unexpected task will be completed by the end of this month. A challenging yearlong campaign of crucial environmental and functional tests will follow, ahead of the inaugural launch scheduled in 2007.

Last year, small technical problems and failures which occurred late in the processing of Jules Verne - such as a small fatigue failure on a propulsion valve and an anomaly on the drive mechanism of the crucial solar arrays - had an impact on the campaign schedule with a snowball effect, delaying the launch by at least one year.

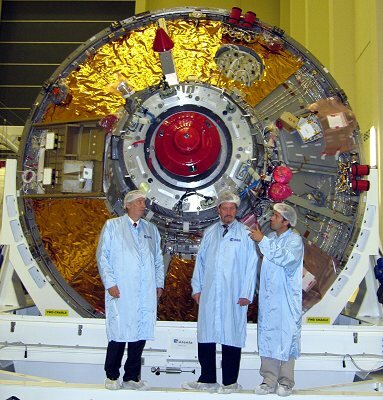

“We need to have a fully integrated ATV with all the flight hardware already tested at the subsystem level to complete the extensive test campaign of the real 19.7-tonne Jules Verne as a whole”, says Bachisio Dore, ESA's ATV Test Manager. 2006 is a crucial year to achieve the complex environmental test campaign - such as the main acoustic and thermal tests - which will take most of the year and will last until the autumn.

In parallel, functional and operations tests have to be performed on the one hand at the Functional Simulation Facility (FSF) - which is the ATV simulation facility at EADS-ST facilities in Les Mureaux, 50 km west of Paris - and on the other hand, at the ATV Control Centre in Toulouse. If all these tests are satisfactory, the most complex space vehicle ever developed in Europe will be ready a year from now for its inaugural trip to Kourou, in French Guiana.

Acoustic tests

The first part of the year will be dedicated to preparing and performing mechanical tests. Acoustic vibrations will be used to simulate the stress the ATV will encounter during the first three minutes of launch - due to aerodynamical forces - on top of the powerful European Ariane-5 launcher.

The whole structure of the ATV, which is the size of a double-decker London bus, will have to withstand frequencies up to 8 kHz with an acoustic level reaching 143 dB. The same amount of acoustic vibrations would be lethal for the human body.

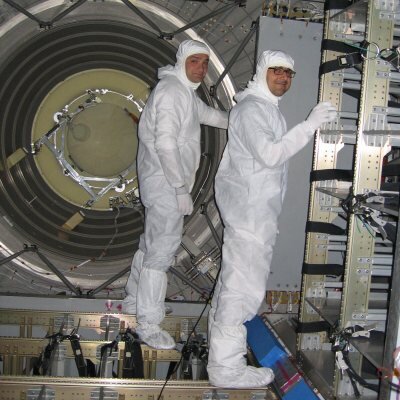

For several days different test runs will be conducted in a special enclosed facility called LEAF (Large European Acoustic Facility). Dozens of sensors placed in different areas of the ATV will measure and check its hardware behaviour. Two-dozen technicians and engineers from Prime Contractor EADS Launch Vehicles, EADS Space Transportation (former Astrium), Alcatel Alenia Space (former Alenia Spazio), Dutch Space (recently acquired by EADS Space), European Test Services (ETS) and ESA will coordinate the test runs.

“Jules Verne will be in the same flight configuration as for launch except for the several tonnes of dry cargo and the propellants,” says Dore. Although the tests themselves will only take four to five days, it takes weeks to prepare the spaceship and to move it between the different facilities at ESA's centre in Noordwijk.

After the acoustic stress test, the next step will be to check the critical deployment of the four solar arrays, which, with their total span of 22.3 meters, provide electrical power to the spacecraft and to rechargeable batteries indispensable for eclipse periods in orbit. Last year, some recurring anomalies on the drive mechanism of the solar arrays forced engineers to add a back-up device to monitor the good angular position measurement of this vital system. Some 95 minutes after lift-off, the ATV activates its navigation systems and deploys its solar panels, which must track the Sun - as early as possible - to get energy while orbiting at 28 000 km/h.

Thermal tests in summer

Detailed computer analysis of the test data acquired during the acoustic tests will continue in parallel to the post-test inspection and reconfiguration of the ATV for the next test campaign. If everything goes as planned, during the summer the ATV will undergo a series of critical thermal tests, under vacuum and with the ATV operational, which replicate the harsh temperature environment cycle of space.

“These thermal tests are the most critical environmental tests to make sure that all the Jules Verne systems are robust enough to withstand the whole six-month long orbital mission”, says Dore. It will be the largest spacecraft ever tested in Europe in almost half a century of space programmes.

From autumn the next challenge for the Jules Verne campaign will be to test the full interaction between the very extensive flight software and the hardware as a whole. Using the Electrical Ground Support Equipment (EGSE), which includes hundreds of cables and umbilical connections and dozens of ground computers, it is possible to replicate the functional environment of the navigation and flight dynamics during the flight of the spaceship.

This was already tested at the Functional Simulation Facility (FSF) at EADS Space Transportation facilities in Les Mureaux, France. This simulation facility includes some of the actual mechanism and flight box replicas, which are the electronic 'brain' and the 'nervous system' of the ATV, and an even larger piece of ground equipment, which simulates all the external interfaces, including up to sixty electronics racks. However, to be sure that the FSF exactly replicates Jules Verne, the results from the two campaigns will be minutely compared.

To make the tests even more realistic, at some point the ATV Control Centre in Toulouse will be added into the loop. The preparation and simulations in closed loop will take up to three months and should take place by the end of the year.

If all the challenges are met according to schedule, Jules Verne will be ready for sea shipment early in 2007. The transportation of ATV by boat from the Netherlands to French Guiana will take two weeks, after which an eleven-week launch campaign will be required before lift-off.

In any case, the actual mission will most likely take place no earlier than May 2007. First, all the international partners have to agree upon the best date to re-supply the Station with the 7.1 tonnes of cargo that is to be carried up by the ATV.