Boxing clever

The first rule of DIY: know where your tools are. Astronauts on the International Space Station are about to have that task made much simpler, with a purpose-designed 3D-printed toolbox due for launch today on ESA’s latest ATV resupply spacecraft.

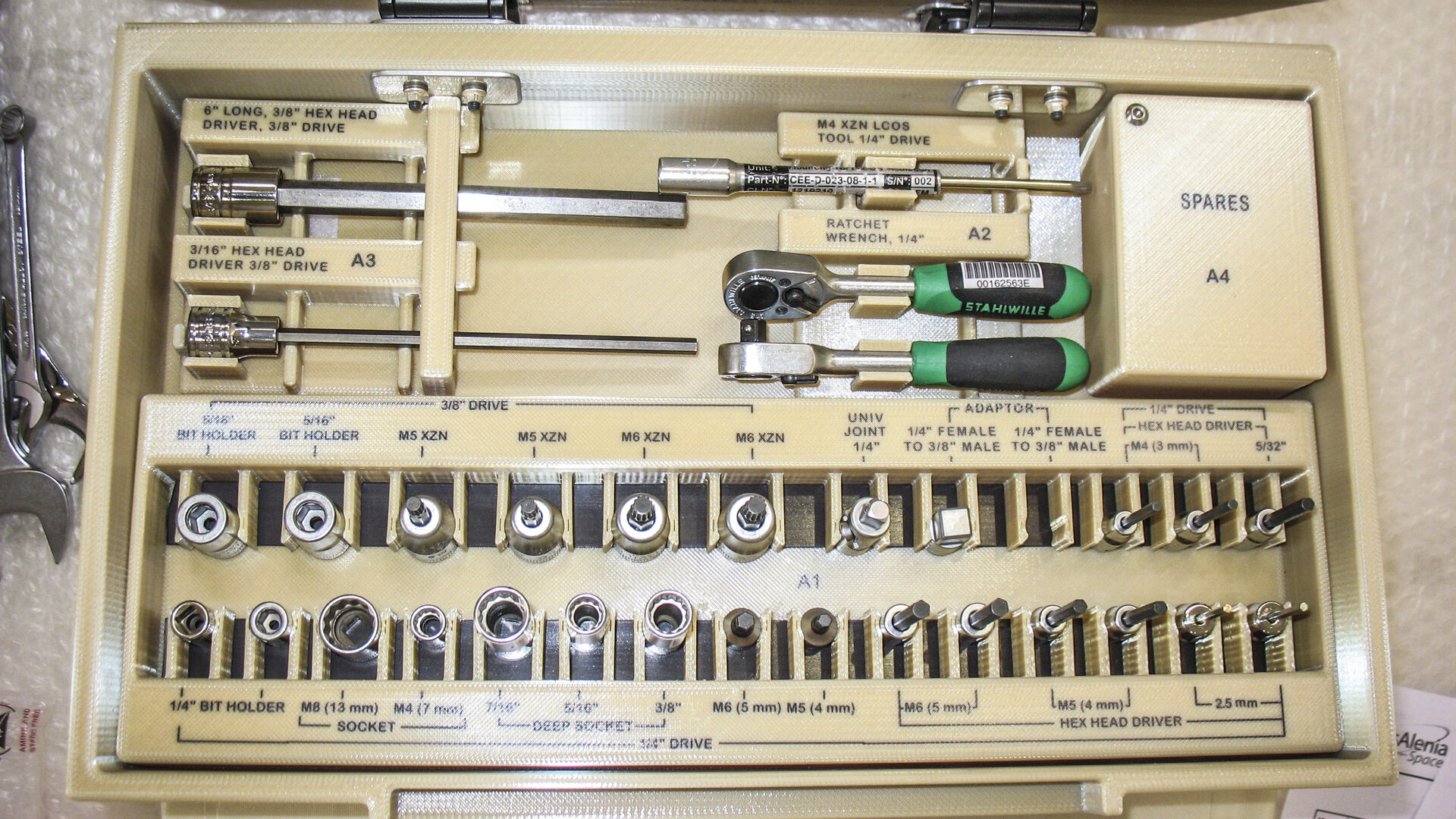

The strong, lightweight multitray toolbox was printed in ULTEM 9085 thermoplastic by Thales Alenia Space in Turin through an ESA contract.

It was then tested by labs in ESA’s ESTEC technical centre in Noordwijk, the Netherlands, for 'offgassing' – the release of potentially harmful vapours in the closed environment of the Space Station – to be sure it is safe for use in orbit.

“The toolbox is designed to store tools for maintaining Europe’s Columbus research module,” explains ESA’s project leader, Bram Bekooy.

“At the moment, there are five separate bags that tools are stored in, but crewmen have complained that this set-up is cumbersome and time-consuming.

“The new toolbox includes little clips to hold the tools in place, just like toolboxes you can buy at a hardware store, instead of the previous Velcro inserts that may lose their stickiness over time.

“At the same time, the toolbox exterior still has Velcro covering, so astronauts can leave it in place while they work without it drifting away.”

ESA astronaut Frank De Winne advised on the design of the box and its accompanying tools.

The tools themselves will fly separately in a soft pouch on ATV Albert Einstein because it turned out to be simpler and cheaper to launch them in a bag rather than have to perform complex vibration testing on the toolbox with all its tools inside.

The toolbox plus tools will be evaluated for practical use by ESA astronaut Luca Parmitano, currently aboard the orbital outpost for a six-month stay.

“An additional advantage of 3D printing is that if any part of the toolbox breaks we only have to reprint and fly up the tray in question rather than the whole box,” Bram adds.

“Similarly, making any improvements we might decide on will be only a matter of updating the computer model, then printing the sections.”

Following this pilot project, future long-duration missions could carry their own 3D printers in space to print out failed parts immediately.

Liftoff is set for 23:52 CEST (21:52 GMT). Watch the launch live on www.esa.int and follow ESA’s ATV blog for mission updates as they happen.