MEMS sensors to guard oil rigs against dangerous gases

A major oil company plans to deploy a new ESA-backed hazardous-gas sensor at its installations. The compact device is based around a half-centimetre silicon chip that seeks out methane.

“Research co-funded by ESA and the Microsystems and Nanotechnology Lab of Norwegian research organisation SINTEF has produced the simplest gas detector possible,” said Benedikt Guldimann, overseeing the project for ESA. “The resulting product is much smaller, robust and reliable than existing systems, with low power requirements and no recalibration needed.”

Based on optical Micro-Electro-Mechanical Systems (MEMS) technology, the sensor operates through tiny voltage-driven shifts of silicon gratings, equivalent in distance to a hundredth the diameter of a human hair.

This sensor technology can be ‘tuned’ to detect particular gases of interest. Apart from obvious space uses, SINTEF foresees it could be applied to air quality monitoring or even low-cost ‘alco-locks’ preventing a car from starting if a driver has alcohol on his breath. Its initial application, however, is to detect methane for the oil industry.

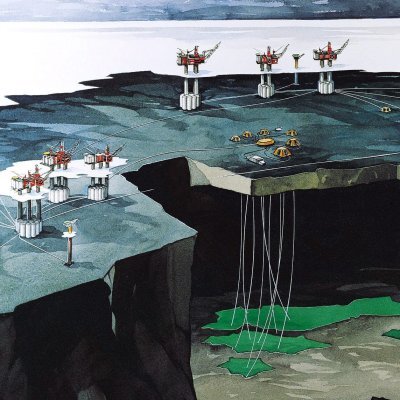

Methane is a colourless and odourless gas, but at high concentrations it can asphyxiate or induce explosions. Methane leaks are a major safety hazard aboard the rigs extracting oil or natural gas from the ground.

Sifting for spectral fingerprints

Like most current gas detectors, the sensor filters light to reveal spectral absorption ‘fingerprints’ left by trace gases in the air it shines through. This is done using a diffraction grating, as developed by 19th century optician Joseph von Fraunhofer.

Noting that a single narrow slit split light in the same way as a glass prism, he found that multiple slits combined into a grating worked even better. These are common today: a DVD’s underside reflects rainbow colours because its narrow tracks act as a diffraction grating.

Gratings can be tailored to reveal particular wavelengths. However, any gas sensor needs not only to measure in its chosen absorbing band but also to make regular reference measurements outside it, to check for residual absorption or scattering not due to the target gas. This seemingly simple requirement makes existing detectors much more complicated.

Adapting micro-technology

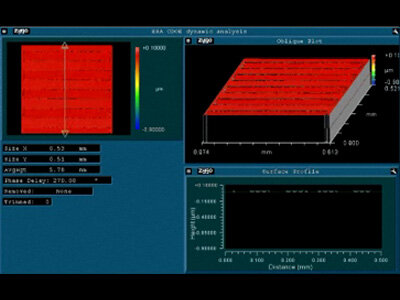

Rejecting bulky solutions such as rotating filter wheels or tilting diffraction gratings, SINTEF’s ‘Controllable Diffractive Optical Element’ (CDOE) instead makes use of optical MEMS technology. Using manufacturing techniques borrowed from the semiconductor industry, this approach employs suspended miniature gratings which shift down slightly when voltage is applied – moving less than one micrometre (µm), which is one thousandth of a millimetre or a hundredth of a hair’s diameter.

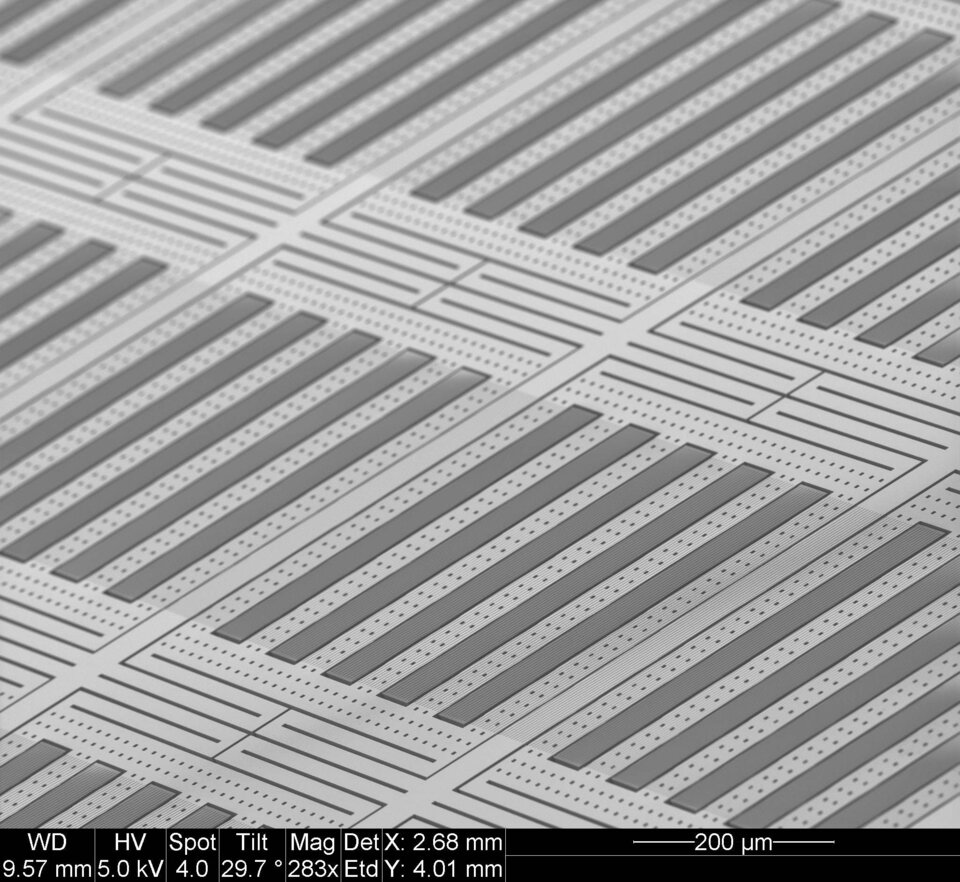

The 0.5 cm sq CDOE area consists of hundreds of microgratings with a reflective aluminium covering, each one measuring 50 µm by 500 µm. Every second micrograting moves when a voltage is applied due to electrostatic attraction, springing back when the voltage is switched off.

This slight motion is sufficient to change the grating’s diffractive properties – in principle the same as when a DVD’s reflected colours shift as it is tilted. At rest the CDOE measures methane levels, when actuated it performs reference measurements. The CDOE is central to the gas sensor, which also includes a near-infrared light source to shine through air samples plus the detector the CDOE reflects its filtered light onto.

“The system’s simplicity of fabrication and operation is its main advantage,” added Mr Guldimann. “It switches rapidly and accurately between wavelengths and its reliability is unaffected by changing temperature or environmental factors. And because it is fabricated in the same way as semiconductor components, the more that are made the cheaper they will become.

“However, for oil rigs the price of the sensor is less important than its reliability – any false alarm shutting down production would be extremely costly.”

ESA’s partnership with industry

The CDOE gas sensor demonstrator was developed by SINTEF with the support of ESA’s General Support Technology Programme (GSTP), aimed at evolving promising engineering prototypes into commercial products.

“The CDOE originated as part of a internal SINTEF development targeting spectroscopy applications in general,” explained Håkon Sagberg, formerly of SINTEF but now overseeing spin-off company GasSecure, set up to exploit the technology. “ESA involvement and co-funding gave the activity a boost, now focused on gas sensing. The resulting MEMS components demonstrated the technology’s commercial potential, enabling the spin-off of GasSecure.”

“GSTP represents a valuable tool for ESA member states looking to bring new technologies to market,” said Rune Eriksen, Head of Industrial Coordination at the Norwegian Space Centre (NSC). “This particular project, facilitated through NSC, is a good example of why Norway is on its way to becoming one of the largest investors in GSTP.”

Space technologies such as SINTEF’s with applications in the offshore oil and gas sector are due to be showcased at the ESA sponsored Space and Technology Park within the Offshore Oil and Gas Event (ONS), taking place in Stavanger, Norway, 24 – 27 August. ESA’s Technology Transfer Programme Office (TTPO), together with its Norwegian technology broker IRIS, will highlight potentially useful space technologies for oil and gas exploration and exploitation.

ESA Technology Transfer Programme Office

ESA’s TTPO supports the transfer of space technology to non-space companies to solve earthly problems. The TTPO facilitates the use of space technology and space systems for non-space applications and to demonstrate the benefit of the European space programme to European citizens. The office is responsible for defining the overall approach and strategy for the transfer of space technologies, including the incubation of start-up companies and their funding.

To find out more about the kind of technologies available, consult the Technology Forum hosted by ESA technology broker MST Aerospace (see right hand link).