ESA BIC Cevotec: a disruptive Fiber Patch Placement technology company

The ESA Business Incubation Centre (ESA BIC) Bavaria start-up company Cevotec enables manufacturers to build complex fiber composites in high volume and quality, by smart process automation based on Fiber Patch Placement technology. Meet them at ILA Future Lab ”FUEL FOR INNOVATION”.

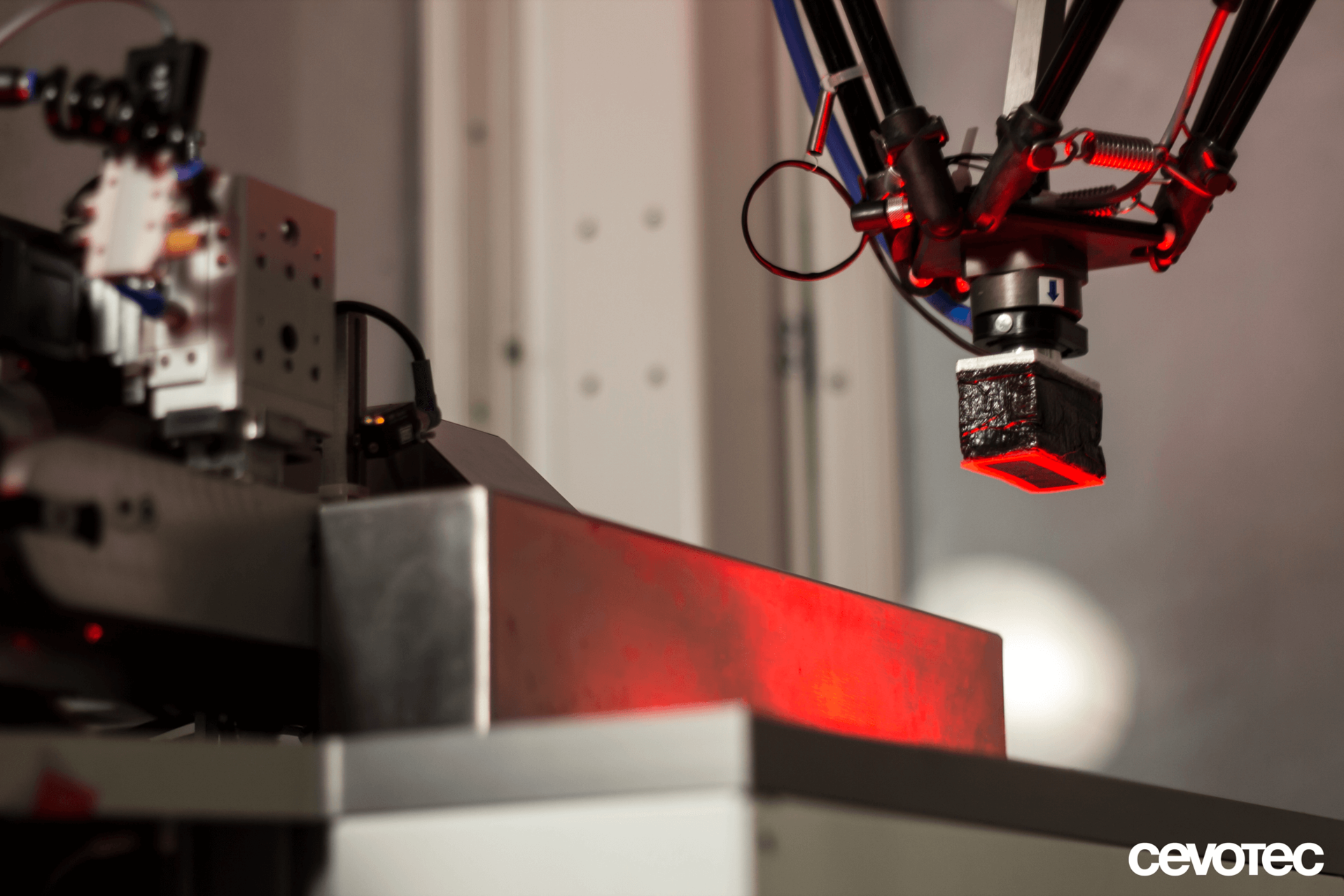

Fiber patch placement (FPP) technology is a robot operated manufacturing technique for making fiber composite objects. The technology is targeted at industrial use in aerospace, machining, medical, sports and automotive industries, e.g. for ski/snowboard reinforcements, helmets and lightweight car parts.

The process works by layering composite fiber patches, that look like scales, over a per-fabricated surface, typically made of wood.

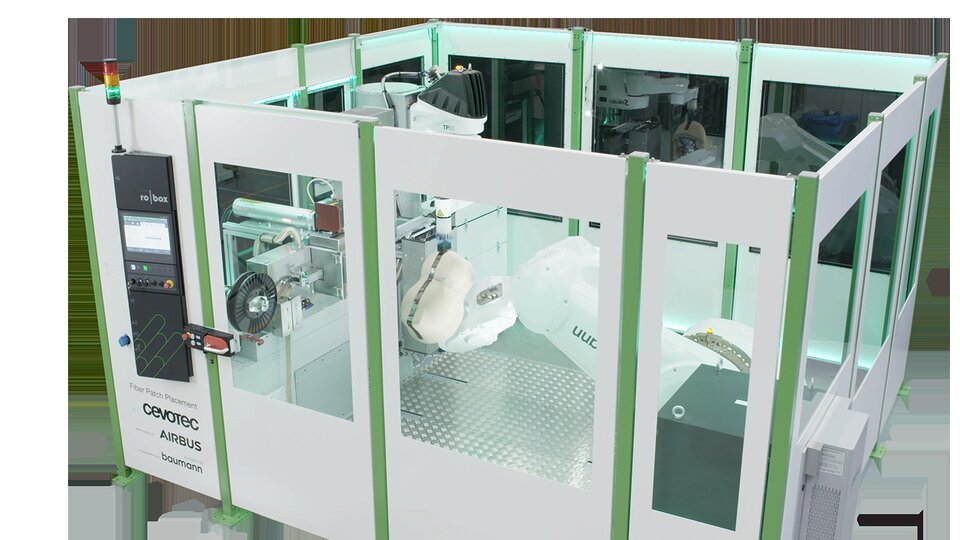

With their innovative SAMBA Series, Cevotec offers tailored, automated fiber layup systems for challenging 3D geometries and laminates with complex fiber orientation.

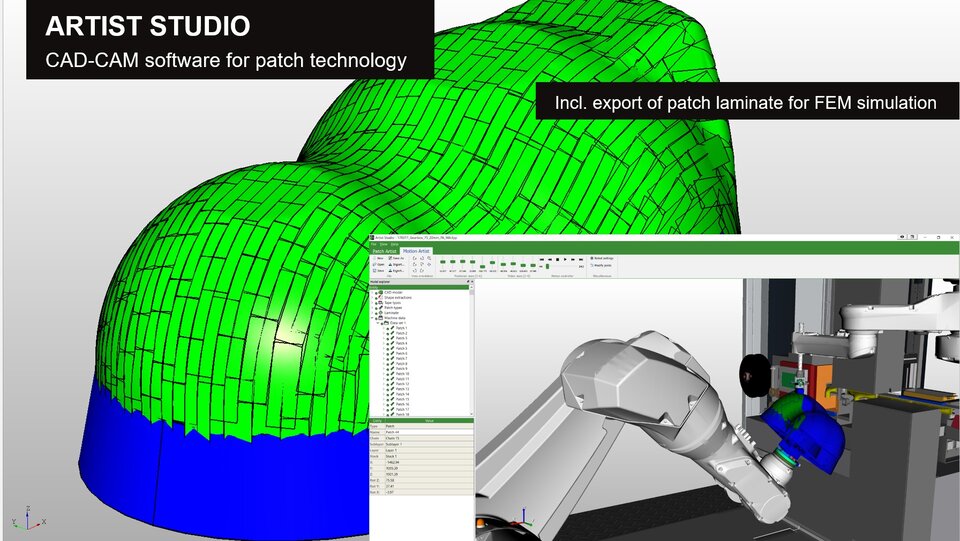

The ARTIST STUDIO is the matching CAD-CAM software for generating patch-based fiber laminates and automated robot programming. Along with development services that include FE-based modelling and simulation, The company offers the entire process chain from digital design to final fiber product.

As the right fiber is crucial for the quality of a composite part, Cevotec has launched its own high-quality dry carbon fiber tape, which is also well-suited for other fiber placement processes like AFP and ATL. Meanwhile, cevoPads are available in prepreg or binder-fixed, dry fiber — both stable and easy to handle in further processing. Different thicknesses are available and individually-tailored reinforcement patterns are possible.

A “truly disruptive” technology

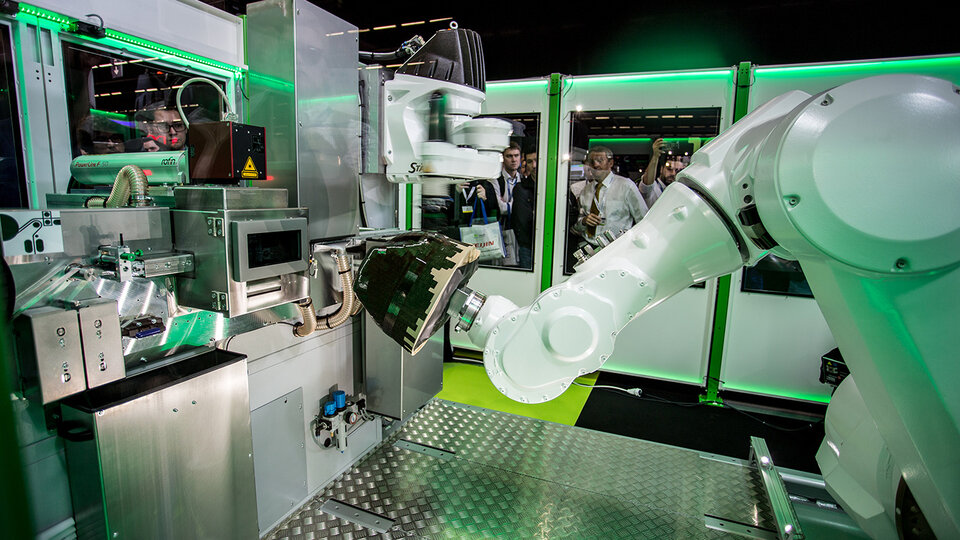

Cevotec attracted quite a crowd to its live demonstration of the automated SAMBA FPP preforming cell at JEC World 2017, in Paris 14-16 March.

“After several sneak previews with our system in a VR [virtual reality] environment, people for the first time could watch SAMBA integrally creating a complex fiber preform: an aerospace gearbox with concave and convex surfaces, including 90° angles and small radii”, said Felix Michl, Cevotec CTO.

Highlights were the speed of one patch per second, the accuracy of the layup and the advantages of the built-in CAD-CAM software ARTIST STUDIO for digital product development.

Existing partners applying the FPP process include Airbus, and German mechanical engineering firm Baumann Automation. For the US marked, Cevotec has partnered with Composite Automation.

“We are very happy to have John Melilli and his team at Composite Automation to introduce the benefits of patch technology to every composite manufacturer in North America” comments Thorsten Groene, CEO Cevotec and one of the founders.

“This technology is truly disruptive,” adds John Melilli, owner of Composite Automation. “From the design to the fabrication of the part, the complete process is managed by the Cevotec software and automation system.”

ESA Business Incubation Centres – ESA BICs

Cevotec is hosted at the ESA BIC Bavaria to develop their innovative solution for manufacturing complex fiber composites in high volume and quality, by smart process automation based on the Fiber Patch Placement technology.

The Technology Transfer and Business Incubation Programme Office of the European Space Agency manages the Space Solutions Programme, which has created the world’s largest ecosystem for space related Entrepreneurship. The 18 ESA Business Incubation Centres (ESA BICs) support 160 companies per year and more than 600 new start-ups have so far been fostered.

At the ILA Future Lab ”FUEL FOR INNOVATION” Cevotec and other disruptive ESA start-ups are on stage together with Head of ESA Technology Transfer and Business Incubation Centre Office Frank M. Salzgeber, ESA BIC Manager Frank Zimmermann and Sabine Dannelke, the Head of Division Satellite Navigation/Galileo, Digitalization of Public Transport at the Federal Ministry of Transport and Digital Infrastructure in Berlin, Germany,

The ILA Future Lab ”FUEL FOR INNOVATION” takes place in the FORUM Hall 2/204 at ILA in Berlin on Thursday 26 April 13:15 – 14:45.