GSTP's burnt bone coating gets us closer to Sun than ever before

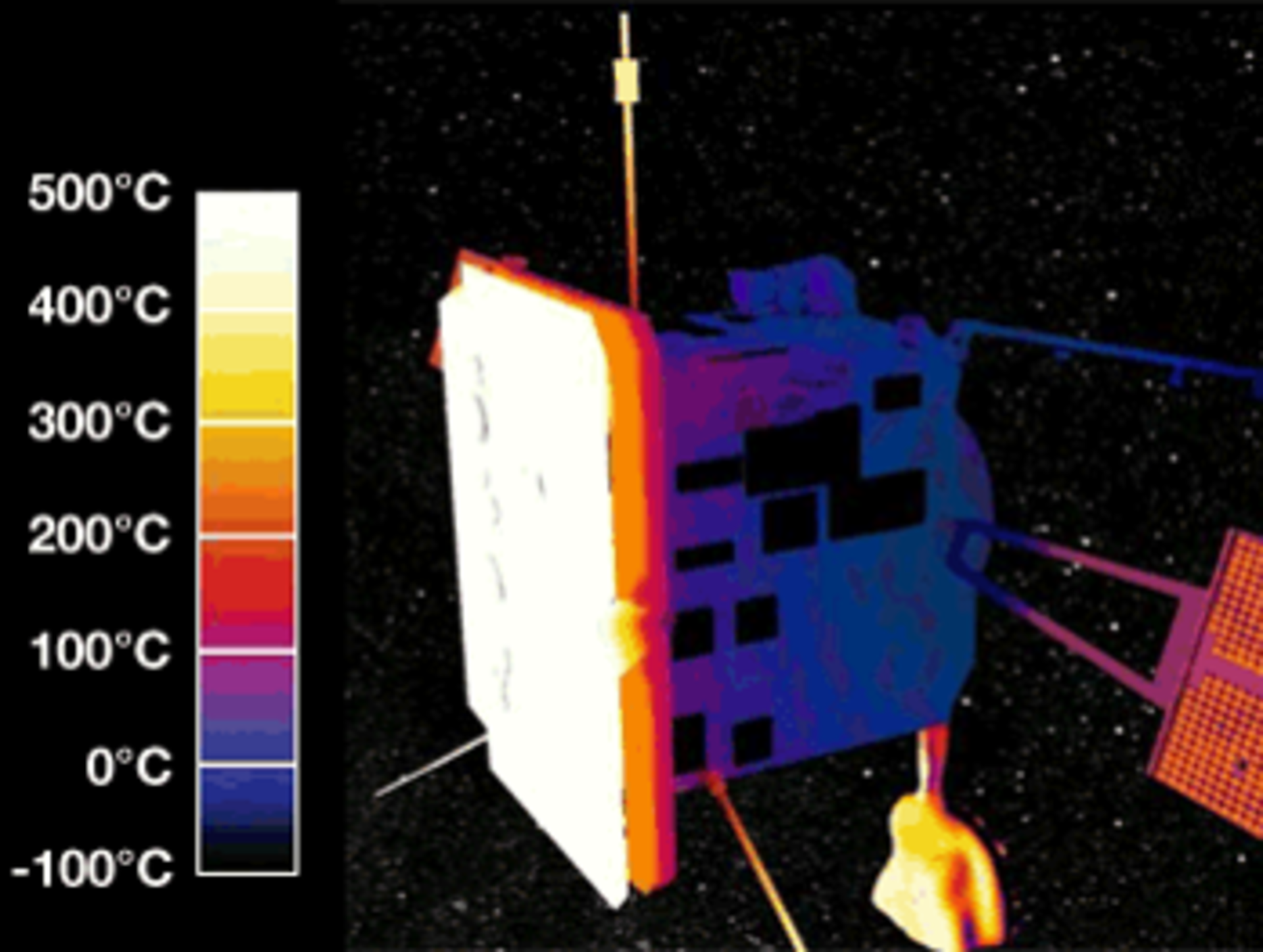

To withstand temperatures of over 500oC around 80% of Solar Orbiter is covered in special heatshielding coatings, called SolarBlack and SolarWhite, designed as part of a GSTP activity with Enbio, in Ireland.

The Solar Orbiter mission is due to launch in early February 2020. The mission, which will help us to understand how our Sun creates and controls the plasma bubbles that interact and influence our solar system, will get closer to the Sun than any man-made object before.

Getting so close requires technologies that can withstand temperatures of over 500oC, something that has only become possible due to special heatshield coatings, called SolarBlack and SolarWhite, designed as part of a GSTP activity with Enbio, in Ireland.

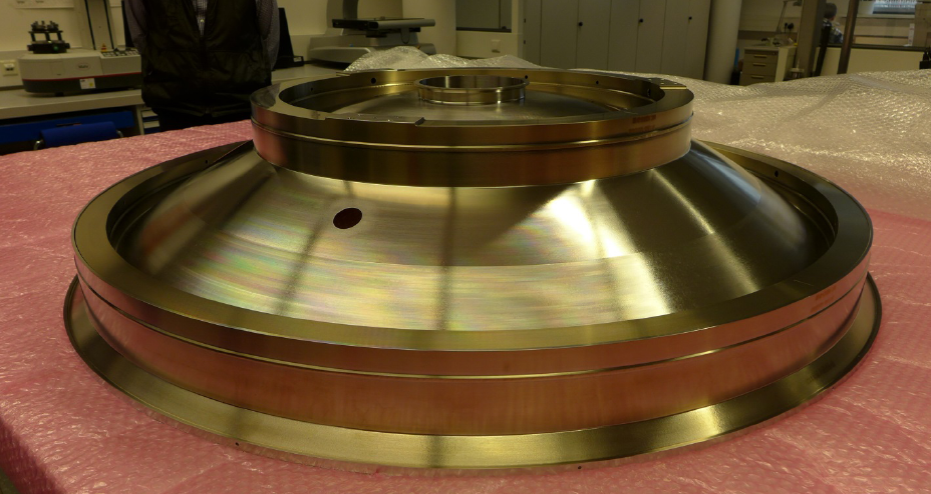

SolarBlack (see image below for an uncoated (left) versus a coated (right) reflector dish) will be the first line of defense for this mission. The inorganic layer is applied on top of a metal treated with Enbio’s CoBlast technique, which replaces the surface of the material with the heatshield skin. In the single-step process, the oxide layer on reactive metals such as titanium, aluminium or stainless steel is removed through grit-blasting and a new substrate – in Solar Orbiter’s case, SolarBlack or SolarWhite – is chemically bonded to the surface before a new oxide layer has a chance to form.

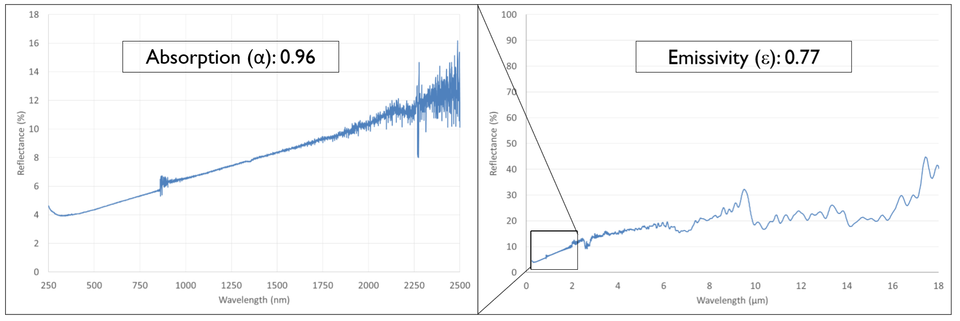

For SolarBlack, the skin applied is made of black calcium phosphate, from widely-used burnt bone char, which has a high emissivity and extremely high solar absorbance so it is able to efficiently absorb incoming solar radiation and re-emit it to the surrounding cold medium of space. SolarWhite is applied over the top of SolarBlack, and is used on many of the instruments. What makes the SolarBlack coating unique, is its ability to be applied to a range of substrates without changing the materials or process parameters.

After undergoing multiple tests in the ESA laboratories, the coatings have been used on more and more parts for the mission from the heatshield to the titanium high-gain antenna and SolarBlack is already in testing for use on the JUICE mission, due to launch in 2022.

CoBlast, SolarBlack and SolarWhite have all been developed as GSTP funded activities and their achievements were highlighted at the Programme’s 25th Anniversary event in Lisbon in 2018.