Removing viruses from astronauts' drinking water

Water is a vital resource, needed by any crew members so that they can live aboard a spacecraft. It is also, largely, the most critical in terms of mass.

To date for space exploration, water has always been transported to space from Earth, with very limited quantities being recycled onboard the space craft.

But as missions become longer and further away, water recycling will become an essential component of any future exploration and with it new challenges for crew health and payload integrity.

Currently, water recycling is limited to water recovery from cabin condensation and urine. In

the Russian segment onboard the International Space Station, cabin condensation is processed to levels suitable for either hygiene or drinking water quality for Russian standards. Silver biocide is added to purified water and water is pasteurised before consumption. In the US orbital segment, the water recovery system allows urine and cabin condensation recycling to potable water according to US standards.

The last decades of manned missions have observed microbial contamination, including pathogens, during the Skylab, Apollo and now ISS missions. They also reported higher microbial virulence, as well as antibiotic resistance and growth rate of model micro-organisms cultured in-flight and antibiotic resistance by the crew micro-flora. This leaves the crew more susceptible to allergies and illnesses.

In addition, several pieces of hardware were biodegraded, for example through a biofilm forming on the surface.

These observations lead to the establishment of microbial standards for the air, water and surfaces, specific medical procedures, as well as monitoring and decontamination procedures. Today, monitoring of microbial contamination uses traditional methods of culturing bacteria.

But this method is not conducive to space applications as culturing microbes brings with it the risk of actually spreading microbial contamination and the need to decontaminate the media when the analysis has been completed. In addition, there is no universal culture medium that allows the growth of all bacteria, therefore the results may be an underestimate of the real number of bacterial present, and the method does not allow the distinction between pathogenic bacteria and non-pathogens. Finally, viruses and parasites require specialised methods for detection and these organisms are frequently associated with contamination of water and subsequent human illness on Earth.

Today, these methods require an incubation period of several days and consequently fast corrective action cannot be taken.

In light of this, an important challenge for water microbial quality monitoring is the development of a real-time risk-based, rapid, specific and sensitive detection of appropriate microbial indicators and waterborne pathogens, which may include not only bacterial pathogens but also viruses like Norovirus.

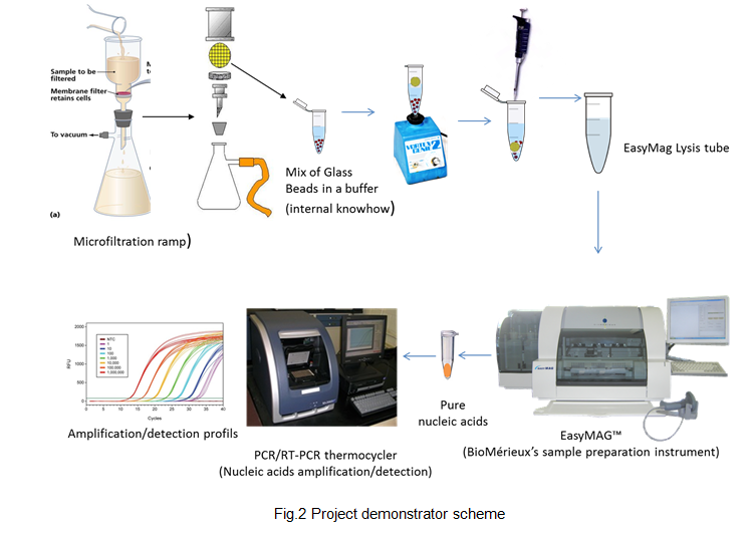

A TDE activity with bioMeriéux in France aimed to do just that, by defining a water-specific sampling and preparation module improving on the current detection module and system.

The intention was that the new module would have the advantage of being a single system capable of monitoring the air, surface and water quality on long duration space flight, ultimately reducing the required payload mass.

The activity focused on selecting and demonstrating an efficient bacterial concentration technology from tap water at the terrestrial level and then integrating the future space constraints.

A breadboard was built of the module, which functioned using a flat polycarbonate filter with specific features for the concentration function. The device was initially designed to sample air not water. In this design, a sliding flap is opened at will for impacting the air on a glass beads layer, retained by a mesh. A water-sampling adaptation can be designed by adding the flat filter under the glass bead layer. In particular, it is compatible with the existing water loop and easy to operate by the crew.

This breadboard was shown to be able to concentrate below 50 bacterial colony-forming units per milliliter -- the target for the first pathogen screen to ensure crew safety.

Next, the activity plans to bring the selected technology to a MIDASS-integrated spatial level, with a design and performance risk assessment.

All deliverables for the activity T321-026MC were received in May 2020.