Characterisation of Metallic Materials

| Programme: | TRP Workplan | Achieved TRL: | n/a |

| Reference: | T724-407QT | Closure: | 2016 |

| Contractor(s): | AAC (AT) | ||

Within the framework of the European Space Industry there is a continual need to review the properties of existing and new materials and processes and characterise their performances. As part of its remit to guarantee suitability of materials, processes and parts for the intended use the Materials and Components Technology Division (TEC-QT) is coordinating and running a series of external laboratory facilities, complementing the ones maintained in ESTEC. Routine, but also extreme environment testing characterization and teaching programmes have been assigned to a network of European institutions which are managed and maintained by the TEC-QT Division.

Objectives

To cover a programme of tests, theoretical analysis and experimental investigations and to acquire data for ESA projects and supplement the metallic materials data existing in the present ECSS Product Assurance requirements, ECSS-Q-ST-70.

Achievements and status

- 9 ad-hoc material investigations to solve direct project issues

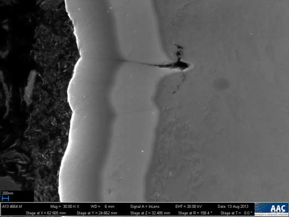

- 35 SCC tests on different materials according to ECSS-Q-ST-70-37

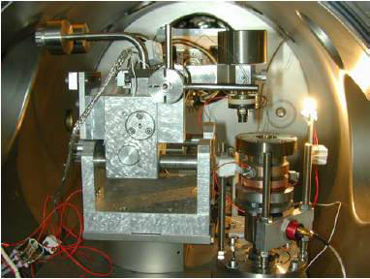

- 5 Cold-welding test campaigns including the development of new test methods

- 7 Microstructural characterisations

- High temperature solder testing for Surface Mount Technology

- Fatigue testing

- 4 Literature studies

- Development of new test equipment/methods for solder testing and lubricant testing

Next steps

Establish a new frame contract and continue the excellent support of ESA projects