Development of a Methane Recovery Unit

| Programme: | GSTP | Achieved TRL: | 4 |

| Reference: | G513-036MC | Closure: | 2016 |

| Contractor(s): | CMR Prototech (NO) | ||

Methane is formed as a product of air revitalisation on-board spacecraft (Sabatier reactor) and within the Micro-Ecological Life Support System Alternative (MELiSSA). By its nature, the methane molecule represents a mass in carbon and hydrogen. As these two elements are core elements of organic chemistry, they deserve to be seriously studied for the closure of life support system cycles. Unfortunately, today methane is known to be an end product of the said recycling processes. Many investigations have considered using methane for electricity production or propulsion, but these processes are so far of poor efficiency and require a high level of purity. It is therefore important to also review and study new processes for an efficient stoichiometric transformation of methane to useful products, and to demonstrate its feasibility at a conceptual level.

Objective(s)

The study logic determines a preliminary definition of top level requirements for a methane recovery unit (MRU) for space missions. Proceeding to identify all possible methane recovery technologies for ECLSS, check against the requirements and a trade-off study to identify the most promising one and conduct feasibility tests of the chosen technology.

Finally to deliver a conceptual design of a device for methane recovery in ECLSS, with defined future work to be performed for the development of an MRU.

Achievements and status

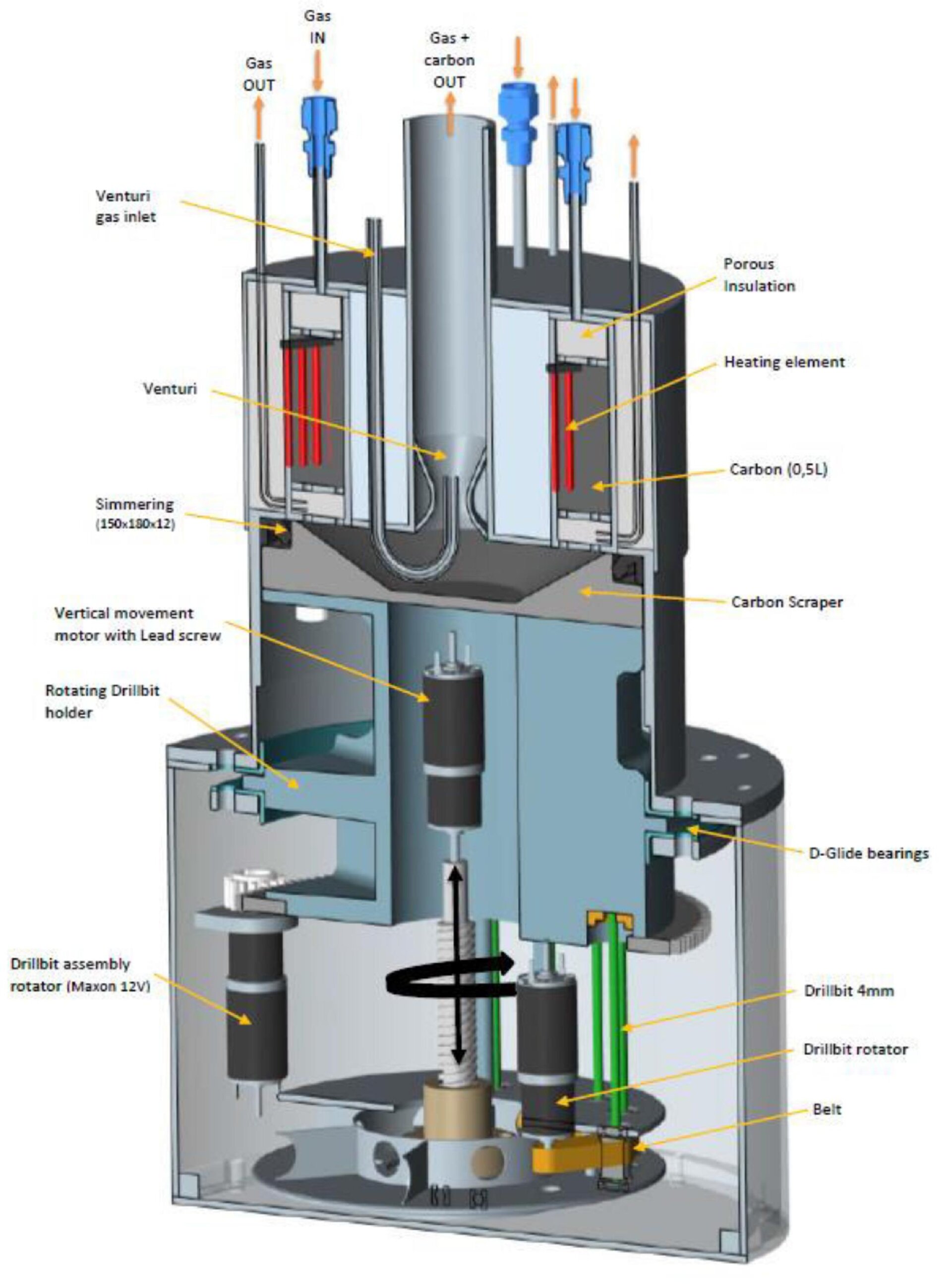

Several possible products of methane decomposition were identified as potentially useful, a set of criteria were established for the trade-off, based on modified ALiSSE criteria. Methane pyrolysis scored highest, feasibility testing of the methane pyrolysis technology based on carbon catalyst demonstrated the process in a reactor scaled to a 6-person crew (reaction volume of 2 l) and assess the efficiency, energy consumption, process kinetics, optimal reaction conditions and suiting / wear of the equipment. The use of carbon catalyst (active carbon) allows one to reduce the pyrolysis temperature to 800-900 °C, decreasing the requirements for the construction materials and lowering energy consumption. Based on the findings of the feasibility tests, a conceptual design of a methane recovery unit with carbon catalyst is proposed. The reactor is designed to fully exclude the need for human maintenance during normal operation, Carbon removal too, is fully automated. The total weight of the concept reactor is 23,7 kg excluding the insulation and electronics, and volume is about 17,4 liters.

Benefits

Immediate application is in closed loop ECLSS, however, the developed methane recovery unit, is an attractive alternative to steam methane reforming (SMR) in production of hydrogen from natural gas. Its main advantages are elimination of CO2 emissions and production of an additional product, solid carbon. The global hydrogen production currently exceeds 50 Mton per year4, suggesting a huge market opportunities for the new technology.

Next steps

The following points were identified to require further work:

- Improve the control over the methane pyrolysis process by adjusting temperature, pressure, reaction time, carbon catalyst type etc. to improve the conversion and products quality

- Find a good strategy for carbon catalyst regeneration

- Assess formation and handling of impurities and by-products

- Develop a system to separate hydrogen from unreacted methane

- Assess the collection and usage of the carbon produced in the pyrolysis unit