Investigation of Friction Stir Welding of Aluminium Lithium Alloys for Manufacturing Spacecraft Propellant Tanks

| Programme: | TRP ITI | Achieved TRL: | 4 |

| Reference: | 4000111807 | Closure: | 2016 |

| Contractor(s): | Airbus D&S (GB), TWI (GB) | ||

Spacecraft missions have been historically predominantly mass driven and therefore titanium has always been the material of choice for propellant tanks. New requirements such as demisability will preclude the use of titanium for some LEO missions. The current generation of Al-Li alloys which have been developed for aerospace applications (e.g. A380, B787) may be a suitable replacement. This activity allows an initial investigation into the suitability to be performed. The activity falls within both Airbus and ESA roadmaps.

Objective(s)

1) To identify a suitable aluminium alloy which could be used to manufacture a full size propellant tank. 2) To identify a suitable joining method which could be used to manufacture the tank. 3) To perform initial welding trials and measure the mechanical performance so that a decision could be made by the industrial lead partner to continue funding the activity to a higher TRL.

Achievements and status

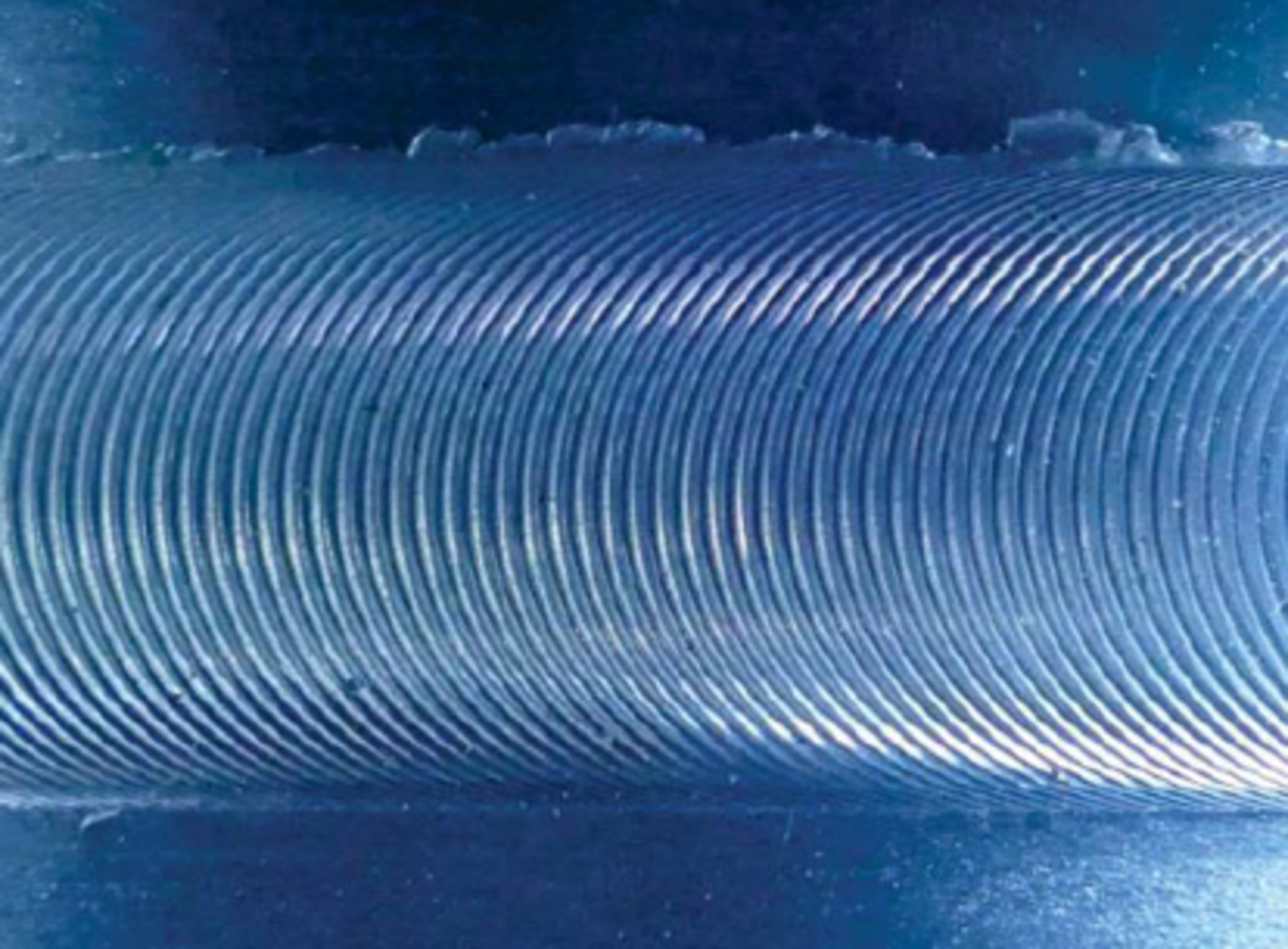

A comprehensive literature search and trade-off study was performed for the selection of the best candidate materials. The results of the trade-offs demonstrated that by switching from titanium to aluminium, there could be a small mass penalty (~10%) which was deemed to be acceptable by Airbus DS. One material was selected for study, namely AA2060 in T3 and t8 temper. For the T3 temper, the average weld efficiency was ~ 97% and in the T8 condition, the weld efficiency was ~ 93%. These values are some of the highest ever recorded for the welding of aluminium alloys. Microstructural and X-ray analysis confirmed that the optimised welds were also free of defects such as cracks and pores.

Benefits

All activities were successfully performed. The mechanical test results indicated that Al-Li alloys could be a suitable choice for the manufacturing of a full size demisable propellant tank.

Next steps

An assessment of the compatibility of the material with standard propellants such as hydrazine needs to be performed. If this proves to be successful, a full size demonstrator will be manufactured.