Polymer Tantalum Capacitor (very low ESR)

| Programme: | GSTP | Achieved TRL: | 5 |

| Reference: | G517-032QC | Closure: | 2016 |

| Contractor(s): | KEMET Electronics Portugal S.A. (PT) | ||

Surface Mount devices (SMD) or technology are regularly used as space components, tantalum capacitors are still widely used in electronic industry and new circuits designs due to their high volumetric efficiency, basic reliability and process compatibility. Solid electrolytic capacitors with intrinsically conductive polymer as cathode material have also additional advantages of low equivalent series resistance (ESR) and “non-burning/non-ignition” failure mode, making them quite attractive to design-in engineers for Space. The electrical characteristics of a Tantalum capacitor are determined by its structure: capacitance, leakage current, impedance/ESR and dissipation factor. Those characteristics are very dependent on the capacitors designs and materials.

Objectives

The primary objective of this project is to develop a European Space grade tantalum SMD chip Capacitor with very low ESR and rated voltage up to 50V, using intrinsically conductive polymer technology as solid electrolyte counter-electrode.

Existing capability of the Évora Plant with actual technology is limited up to 16V rated voltage and to terrestrial application. Since the 1st generation of Polymer Technology has a poor Breakdown Voltage (BDV) performance, not increasing linearly with the dielectric thickness or the number of polymer cycles, as would be expected. This behaviour draws us to a possible degradation mechanism on actual in-situ polymerization that prevents us to achieve higher operating voltages.

Achievements and status

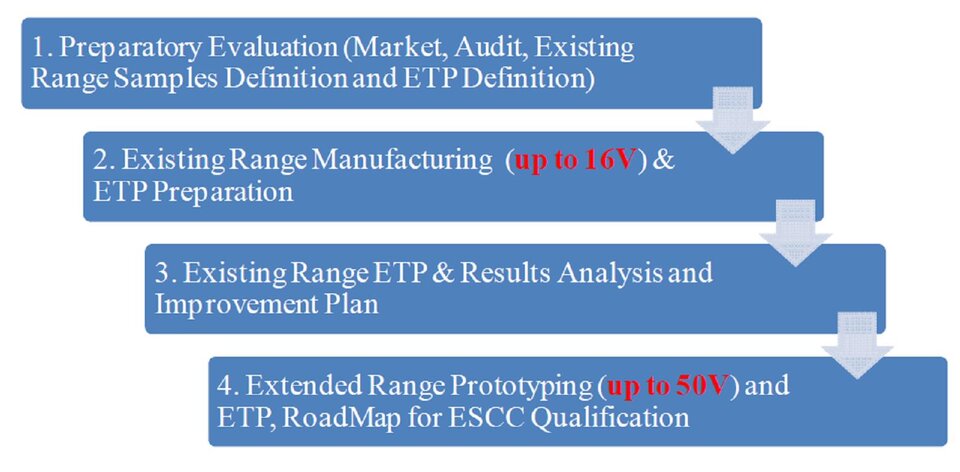

A four phase approach was embarked upon (figure above). The first phase of a preparatory evaluation was with existing description of the Tantalum Polymer Capacitor technology. The main steps of the manufacturing process were established for reference, a baseline of the Electrical Characterization and Qualification data of this existing Technology also highlighting the main benefits towards MnO2 Technology. This lower ESR factor allows targeting some of the most important characteristics of polymer Ta Capacitors, such as better high frequency performance, with a much later capacitance roll-off; opening a new range of high frequency circuit applications. Two hundred components for each type were tested for the evaluation test program. Components were subjected to harsh tests in temperature and humidity, including cycles testing with no major failures, and very good electrical stability: Thermal Shock and Mechanical Capability Tests as Solderability Adhesion, Solderability/ Humidity Sequence or Moisture Resistance. Capacitance shifts were observed as expected but within limits and consistent with the known technology.

The improvement of changing the current polymerization process, by using a combination of the traditional polymer process and the pre-polymerized solution is shown by the Breakdown Voltage behavior. Most relevant improvements to this project was the new process of cathode layers polymerization and optimized aging process across lower temperature and higher aging times of ramp and hold. The definition of the ECSS qualification roadmap will be based on the ETP results.

The picture above displays the 2nd-Generation Conductive Polymer (applied from prepolymerized dispersion) vs. the 1st-Generation Conductive Polymer (applied by in-situ oxidation of monomer to conductive polymer).

Benefits

Polymer Tantalum Capacitor can be used in projects covering all service domains. Usage in the market of T583 and subsequent MAT Ultra low ESR capability extensions has primary targeted the space segment and extreme high reliable applications. Nevertheless, potential non-space applications can be explored in both in Military and Aero-space applications. Commercial grade products can also benefit from the technology.

Next steps

Intent for an EPPL application, to manufacture and qualify samples submitted to QPL Testing. Phase I of this project based on Low Voltage polymer Technology, advance to phase II with high Voltage polymer technology and covering urgent need of capacitance and voltage increase. The MAT - Multiple anode construction validation and qualification process needs to be consolidated with ESA.