Microscopic surface topography and 2d roughness profilometry

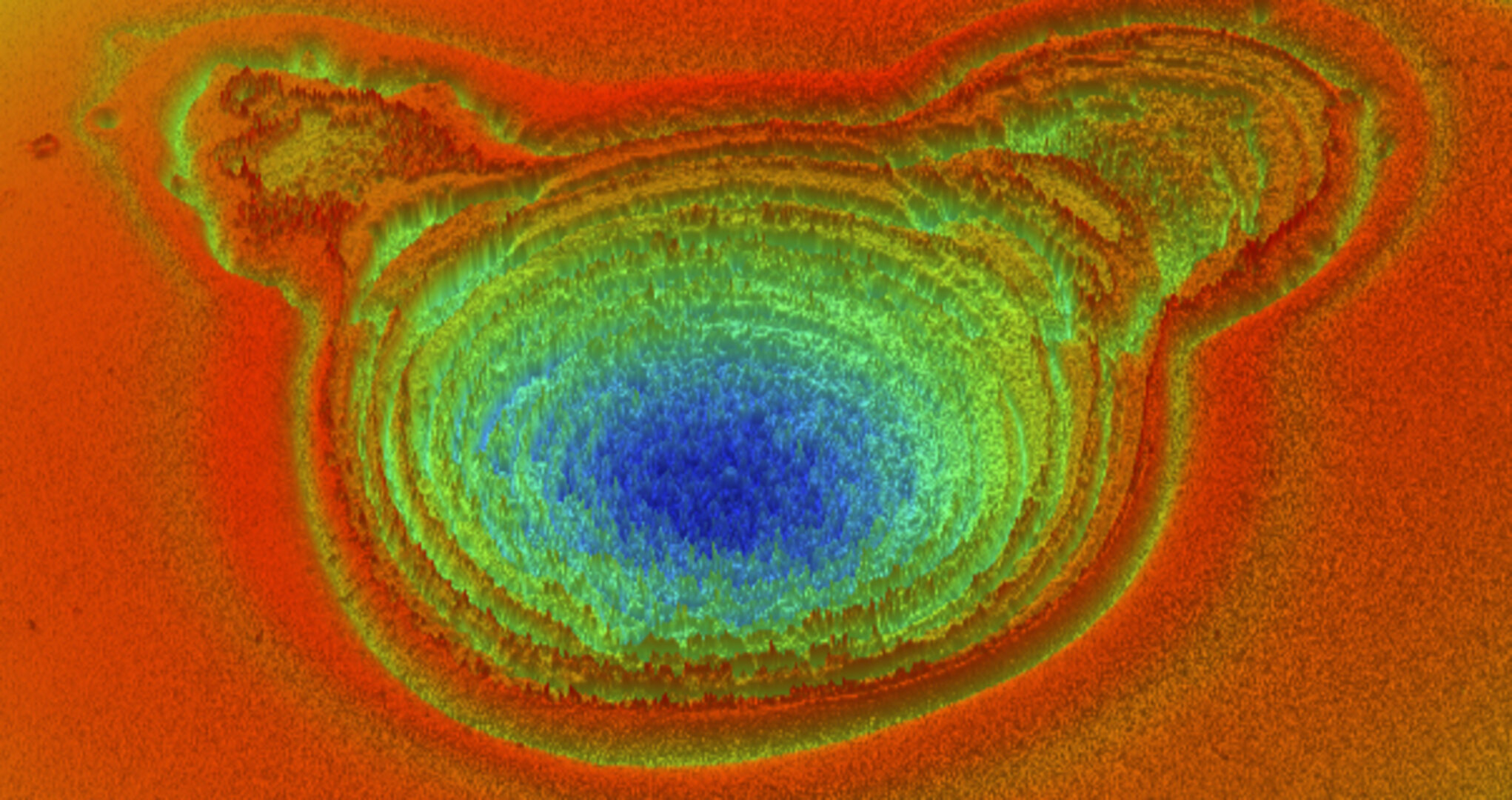

Once an optical component or coating has been manufactured the topography of the surface finish at a microscopic level needs also to be measured, as this can have a direct influence on the straylight or robustness of the surface against damage and contamination. By using white light interferometry with special microscopic objectives, small areas (mm x mm or less) of a surface can be imaged in 3d to produce a topographic mapping with height resolution in the nm (billionth of a metre) range or better. These measurements are quantified and allow the precise shape and height of defects to be determined. The microroughness of the surface area imaged can also be determined over a defined range of spatial frequencies.