Electrifying spacecraft propulsion

Neil Wallace, electric propulsion engineer

Electric propulsion has been around for a long time –1920s rocket pioneer Robert Goddard wrote about it. Perhaps it was an idea ahead of its time, because when I got into the space industry the thinking was that chemical thrusters were good enough, certainly for telecom missions. The platforms were small, working lifetimes were limited, power availability was constrained – and electronics didn’t last that long then either. All that started to change around the turn of the century, with a creeping up of mass, lifetime and power that made the various electric propulsion technologies more attractive.

From Ariane 5 rockets to small onboard thrusters, standard chemical thrusters work in the same way, squirting together chemicals that react in the form of heat, sending out exhaust to trigger an acceleration. These face a fundamental upper limit on performance however, set by the amount of energy in the chemical reaction that heats the ejected propellant, producing the thrust.

Electric propulsion pumps extra energy into the thrust reaction to reach much higher propellant velocities – up to an order of magnitude or so more – because their propellant is accelerated using electrical energy generated by the spacecraft solar arrays.

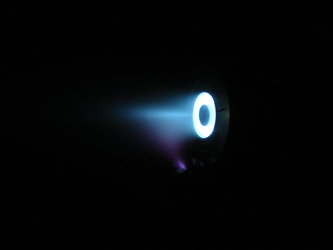

There are a wide range of different engine designs, starting with resistojets that simply use a heater on exhaust gases, to arcjets that pass a current through them, to Hall effect thrusters – a Russian speciality which has found commercial success – based on ionising propellant and then the highest-efficiency gridded ion thruster I’ve done a lot of work with, and has been applied to ESA’s GOCE and now BepiColombo missions.

Access the video

Gridded ion thrusters reach very high exhaust speeds – typically an order of magnitude greater than chemical thrusters – because ionised propellant is accelerated through a set of high-voltage grids using electrical energy, freely available from solar arrays.

Much less propellant is required, although the down side is that thrust levels are much lower and therefore the initial spacecraft acceleration is also low, around the the weight of a Euro coin to start off with – meaning the thrusters have to keep firing for long periods to be effective. However, in space there is nothing to slow a spacecraft down, so the craft’s velocity ends up increasing dramatically. Assuming the same propellant mass, our T6 thrusters can accelerate BepiColombo to a speed 15 times greater than an equivalent chemical thruster.

The difficulty has been developing them, of course. There’s a physics side to understand and then an engineering side as well, to optimise the materials, achieve stable gas discharges and so on. What was originally the UK’s Farnborough Royal Aircraft Establishment, now the QinetiQ company has been researching electric propulsion since the early 1960s. These high-temperature thrusters require utmost reliability through thousands of on/off cycles, amounting to tens of thousands of hours of testing.

What's needed next is a shift in scale - it took four years to build these four Bepi Colombo flight models, the real challenge would be to speed up production

The initial result was the 10-cm diameter T5 thruster, which became a key enabling technology for ESA’s gravity-mapping GOCE mission. Because GOCE stayed in the lowest possible orbit for maximum gravitational sensitivity, it needed a continuously throttling thruster to overcome constantly-varying drag from the thin vestiges of atmosphere. GOCE’s drag compensation system operated continuously throughout its four-year lifetime, responding in tenths of a second – the mission only ending when its xenon fuel finally ran out. Then came the scaled-up 22-cm T6, four of which will propel BepiColombo into Mercury orbit after its 2018 launch. The mission would not be realisable in its current form without them.

What’s needed next is a shift in scale. It took four years to build these four BepiColombo flight models, the real challenge would be to speed up production so the technology could be routinely available for missions – including large scale mega-constellations to come.