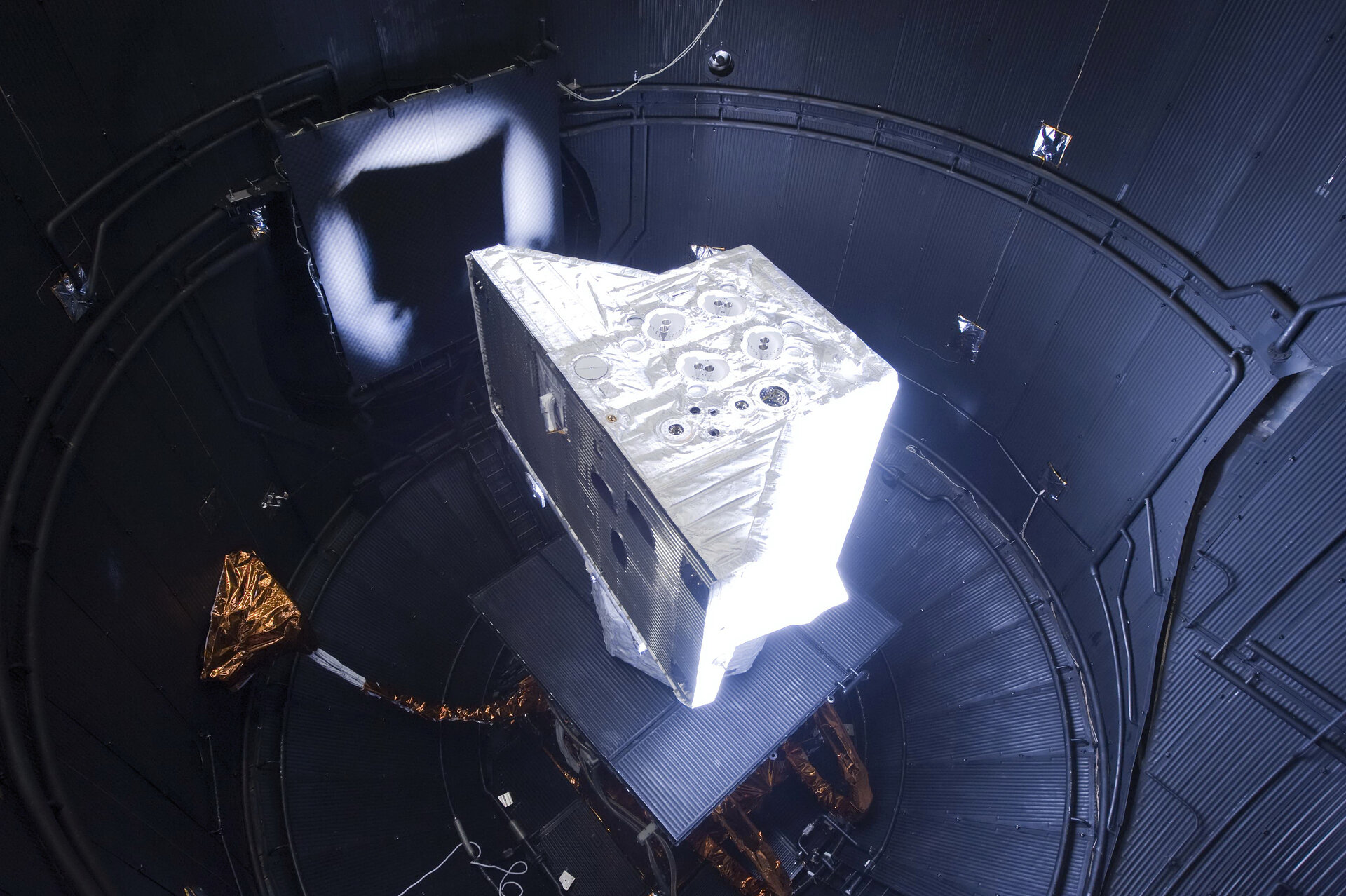

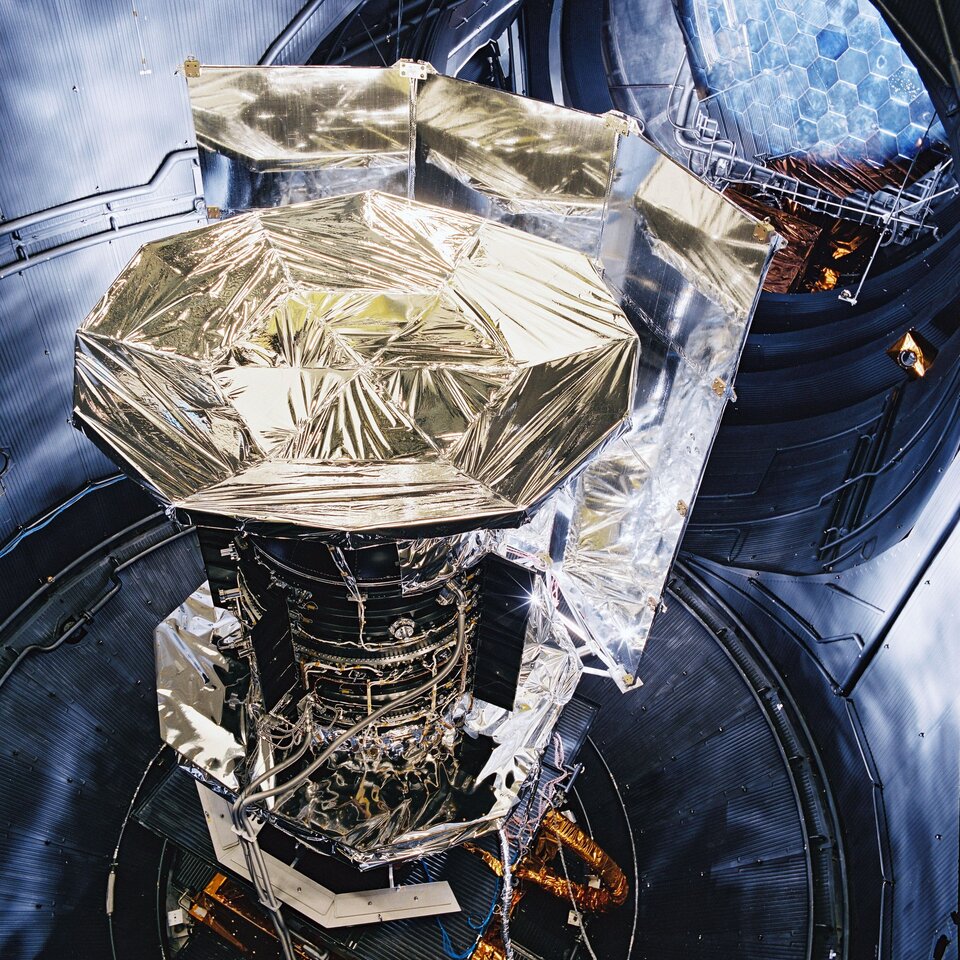

Large Space Simulator (LSS)

What is it for?

The Large Space Simulator is Europe's single largest vacuum chamber. It is a cylindrical container standing 15m high and 10m wide. The Simulator is used to test full-size spacecraft in representative space conditions.

The Simulator's high-performance pumps can achieve a vacuum a billion times lower than standard sea level atmosphere, while liquid nitrogen circulated around the Simulator approximates the cryogenic temperatures of space.

An array of powerful xenon lamps can reproduce the unfiltered sunlight encountered in Earth orbit, or turned up even higher to duplicate the energy intensity experienced closer to the Sun. Hardware can also be rotated in order to reproduce characteristic orbital motion as testing proceeds.

What kind of testing does it carry out?

The Large Space Simulator's close simulation of in-orbit environmental conditions allow a broad range of tests to be carried out in support of design optimisation and verification of spacecraft and payloads.

The Simulator is used for both thermal and mechanical testing. Thermal control designers work to define fixed temperature limits for space structures – if a satellite gets too hot or too cold then mission performance could be affected. Infrared thermography can be used to map hardware temperature patterns, with thermal tests in the Simulator can continue for weeks at a time to ensure that the test item stays within its forecast temperature range.

Extreme temperatures can also cause expansion or contraction of spacecraft materials, defined by their 'coefficient of thermal expansion'. This can cause disruption to the satellite platform and subsystems, and induce micro-vibrations and even stress fractures.

'Thermal vacuum cycling' testing reproduces the rapid temperature shift caused as orbital spacecraft move in and out of sunlight. A scanning technique called 'photogrammetry' is used to obtain precision deformation measurements.

For mechanical testing, the deployment of complete large structures such as folded antennas or solar arrays can be performed in representative space conditions – vacuum and temperature extremes having the potential to interfere with such manoeuvres. 'Dynamic balancing' testing is also performed, where a satellite can be spun around its axis.

Continue reading below

What are its features?

The Large Space Simulator has an overall volume of 2300 cubic metres. It consists of:

Main chamber – A vertical cylinder, the top flange of which forms a removable lid for easy loading into the chamber. An additional 5-m door - with a man-sized door inside it for fast access – is also available on the lower test-floor level. Inside is a stable specimen-support platform, mechanically decoupled from both chamber and building movements providing a very quiet mechanical environment. This is very important for dynamic tests, optical calibration and heat-pipe operations during heat balance phases. Numerous flanges and ports for instrumentation and observation.

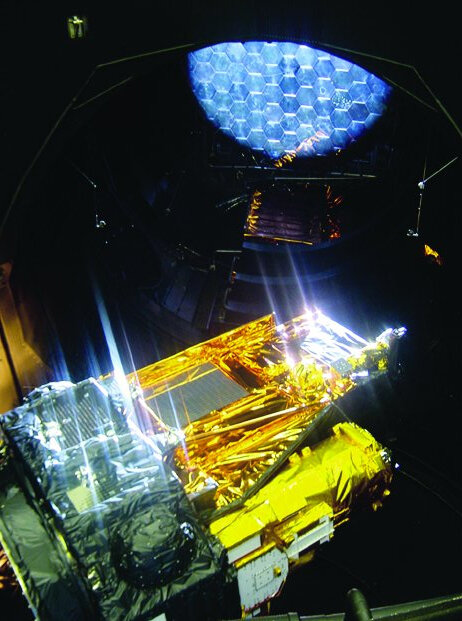

Auxiliary chamber – A horizontal cylinder that provides a stable interface with the solar simulation optics and houses the lens producing the parallel beam on a rigid support structure.

Shrouds – Both main and auxiliary chambers are equipped with a number of stainless steel shrouds that are temperature controlled, using liquid or gaseous nitrogen, in a range from 353 down to 100 Kelvin depending on the operational mode selected. Engineers can independently control the shrouds in both chambers, allowing various temperature combinations.

Sun simulator subsystem – This provides a horizontal solar beam of 6-m diameter with excellent uniformity and very high long- and short-term stability (less than 0.5%). An intensity level of one solar constant (the standard solar energy received at Earth distance from the Sun, equivalent to 1380 watts per square metres) can be produced by operating 12 of 19 xenon lamp modules at a nominal power of 20 kilowatts per lamp. With all lamps at full power, engineers can achieve flux in excess of 2700 watts per square metre.

The Sun simulator therefore has a high degree of redundancy which means that engineers can carry out tests for long periods or at high intensities.

If required, engineers can also equip the Sun simulator with 32 kilowatt lamps.High-vacuum subsystem – The simulator chamber is depressurised using both the totally oil-free central pumping system and a dedicated high-vacuum system. A typical vacuum level of one-millionth of a millibar is achieved using turbo-molecular pumps and two closed-cycle refrigerator cryopumps. One liquid helium cryopump is available in the auxiliary chamber if engineers require extra pumping capability.

The chambers are vented using nitrogen gas to up to 100 millibars and then with clean air up to atmospheric pressure. The total venting time can be adjusted from four to 24 hours depending on needs.

Two independent cryopanels, put into operation early in the chamber evacuation phase and reconditioned only during venting, provide optimum protection against contamination for both the test object and the facility optics.Motion simulator – Users can choose from two motion-simulation configurations, the gimbal stand and the yoke configuration.

Thanks to the two configurations, engineers can place a test article within the Large Space Simulator in almost any position relative to the solar radiation axis. The drive systems and controls make it possible to simulate satellite motion in orbit within a large speed range and high angular position accuracy. As with the chambers, the motion simulator is equipped with thermally controlled shrouds.

A levelling table can be mounted on the yoke or the gimbal stand in order to accurately control the satellite orientation to an accuracy of 0.01 degrees.- Facility Data Handling (FDH) – All the facility parameters are recorded and available in real time for the operators to monitor the test. A dedicated data handling computer collects data for analysis and for detailed fault finding in case of failure.

What benefits does it deliver?

Since first becoming operational in 1986, the Large Space Simulator has proved to be a unique facility that has set new standards in space simulation techniques.

Its exceptional test volume makes it an excellent tool for testing large satellites and systems under conditions very close to those found in orbit. The Simulator has performed thermal and mechanical testing for many of ESA's largest missions including Envisat, XMM, ERA, Herschel and the Automated Transfer Vehicle (ATV).

For more information

Please contact Gaetan Piret, ESTEC Test Centre Manager.

Gaetan.Piret @ esa.int