Liquid propulsion

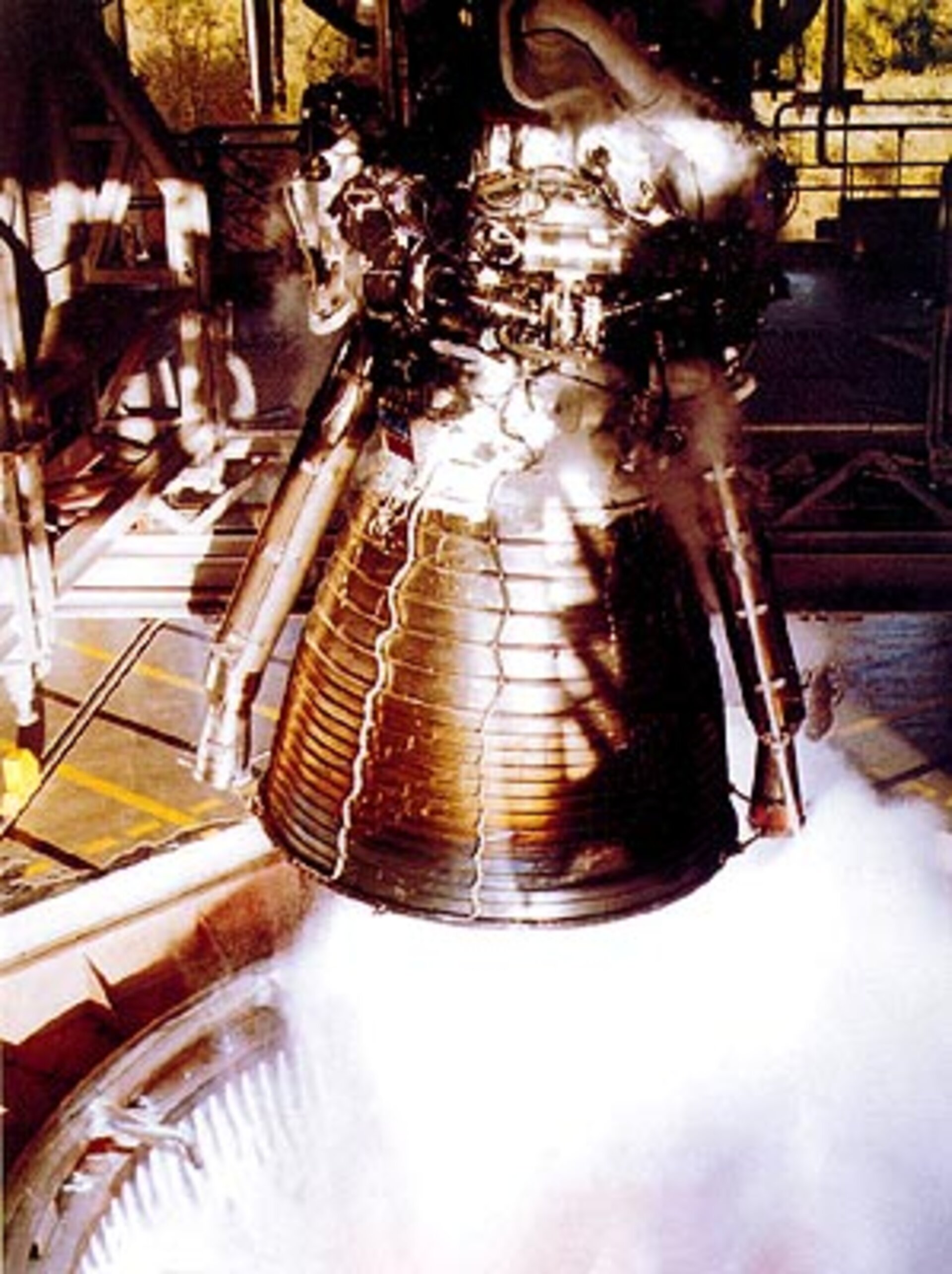

Liquid propellants are stored in the launcher tanks and fed to the engine. As they chemically react and expand in the engine combustion chamber they are forced through the nozzle to provide the thrust that propels the vehicle.

Liquid propulsion technologies under study

Upper-stage engine technologies

A number of new technologies are being developed for an advanced cryogenic expander cycle engine. These include:

- advanced turbopumps for expander cycle applications

- an improved chamber cooling system

- ignition system capable of several re-starts

- ceramic matric composite extendible nozzle

Dual technologies for high-thrust cryogenic engines

Cryogenic engines utilise propellants that are liquid under cryogenic conditions, i.e. at a temperature much lower than normal ambient conditions. The advantage of cryogenic propellants is that they provide the highest performance.

Technologies that can be applied to both low-cost expendable cryogenic engines and reusable cryogenic engines include: fluid bearings, valve electric actuation, new impeller designs, high mass-flow-rate injectors, nozzle sandwich technology and advanced manufacturing methods such as powder metallurgy and casting.

High-thrust liquid oxygen/hydrocarbon engines

Hydrocarbon fuels such as kerosene and methane have the advantage of having high density; this makes their use promising for providing a large thrust in booster applications.

A number of specific technologies need to be developed for this type of engine. These include:

- the mastering of injection, mixing and combustion of hydrocarbon fuels

- turbopump design

- technologies for the pump, turbine and bearings

- injectors and combustion chamber cooling systems

- specific technologies for a LOX-rich (liquid oxygen) environment

High-performance reusable engines

A reusable engine is one that can be reused on a launch vehicle for a new mission. This calls for advanced components such as:

- valves and igniters

- simplified and more robust turbo-machinery (advanced inducers and turbines)

- new injectors, gas generators/preburners and long-life thrust chambers (new materials and new designs)

- systems to monitor engine health

High-thrust demonstration programme

Most of these innovative technologies will be progressively integrated on a high-thrust engine demonstrator of representative size to validate high-performance engine cycles, such as staged combustion.

Reaction control system/orbital manoeuvring system

These systems are needed to help stabilise the launch vehicle on its trajectory, control the attitude of the vehicle during manoeuvres and change the orbit or give the decelerating boost to re-enter the atmosphere.

Technologies for reaction control systems/orbital manoeuvring include:

- the use of green propellants to allow safer handling and more efficient ground operations

- the development of advanced thrusters and ignition systems