Ariane 6: what's it made of?

In brief

Ariane 6 is Europe’s newest heavy-lift rocket, designed to provide great power and flexibility at a lower cost than its predecessors. The launcher’s configuration – with an upgraded main stage, a choice of either two or four powerful boosters and a new restartable upper stage – will provide Europe with greater efficiency and possibility as it can launch multiple missions into different orbits on a single flight, while its upper stage will deorbit itself at the end of mission.

In-depth

Ariane 6 is the latest in the Ariane rocket series, taking over from Ariane 5 with a design that will launch massive missions to low-Earth orbit and shoot intrepid explorers far, far out to deep space.

From solid rocket boosters to an entirely new reignitable engine, what’s going on inside Ariane 6?

Ariane 6 stands at 56-62 m high depending on the size of the passenger its launching. It is taller (and straighter) than the Leaning Tower of Pisa When carrying its cargo or ‘payload’ it will weigh almost 900 000 kg (900 tonnes), roughly equivalent to two fully loaded Boeing 747-8 airplanes.

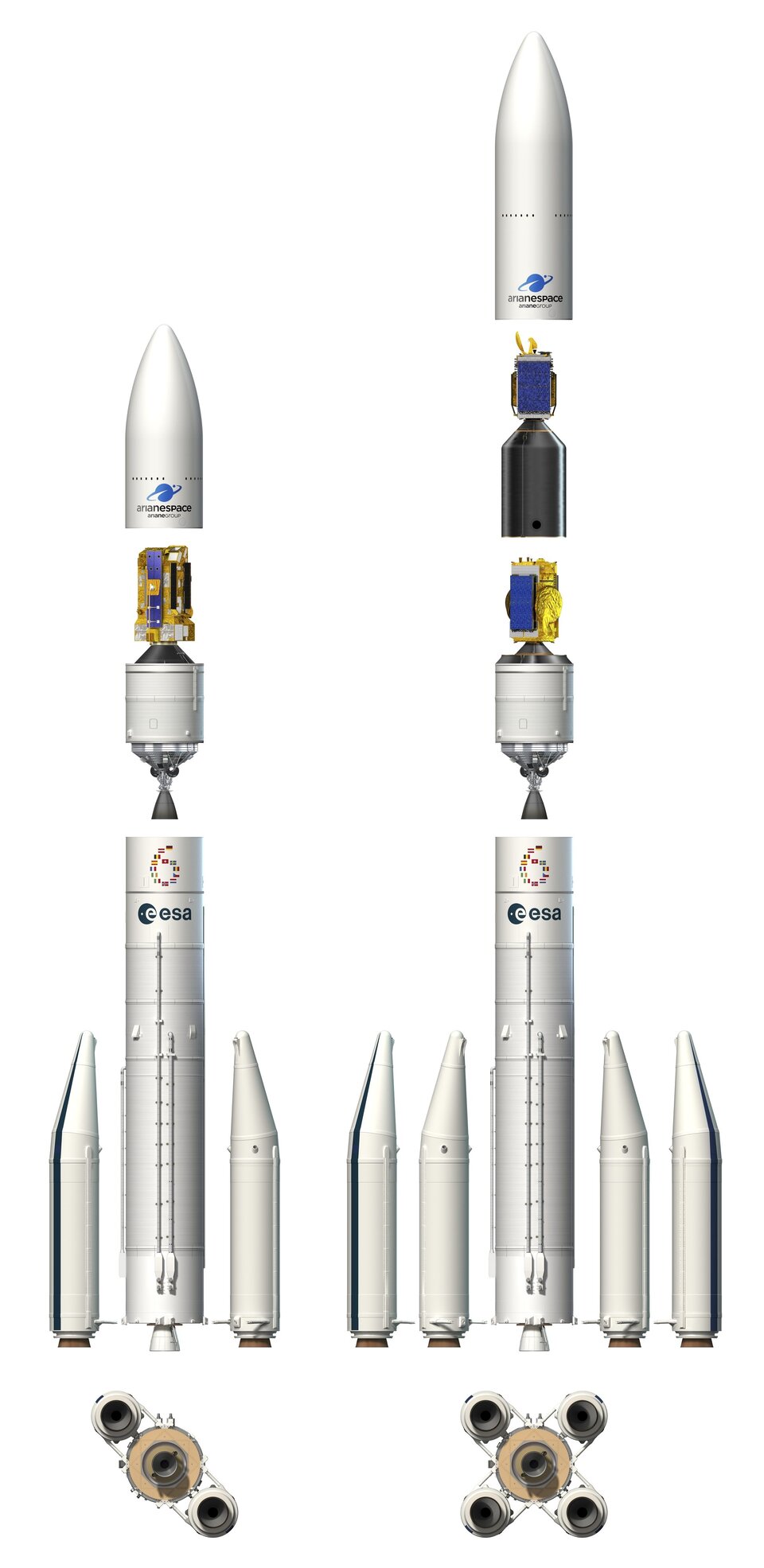

Ariane 6 has a modular structure consisting of three main portions stacked on top of each other: a main stage with either two or four boosters, an upper (orbital) stage and the payload in its fairing.

The new rocket will be available in two versions depending on the amount of thrust required: the Ariane 62 has two P120C boosters and the Ariane 64 has four, providing extra boost for heavier payloads or destinations further afield.

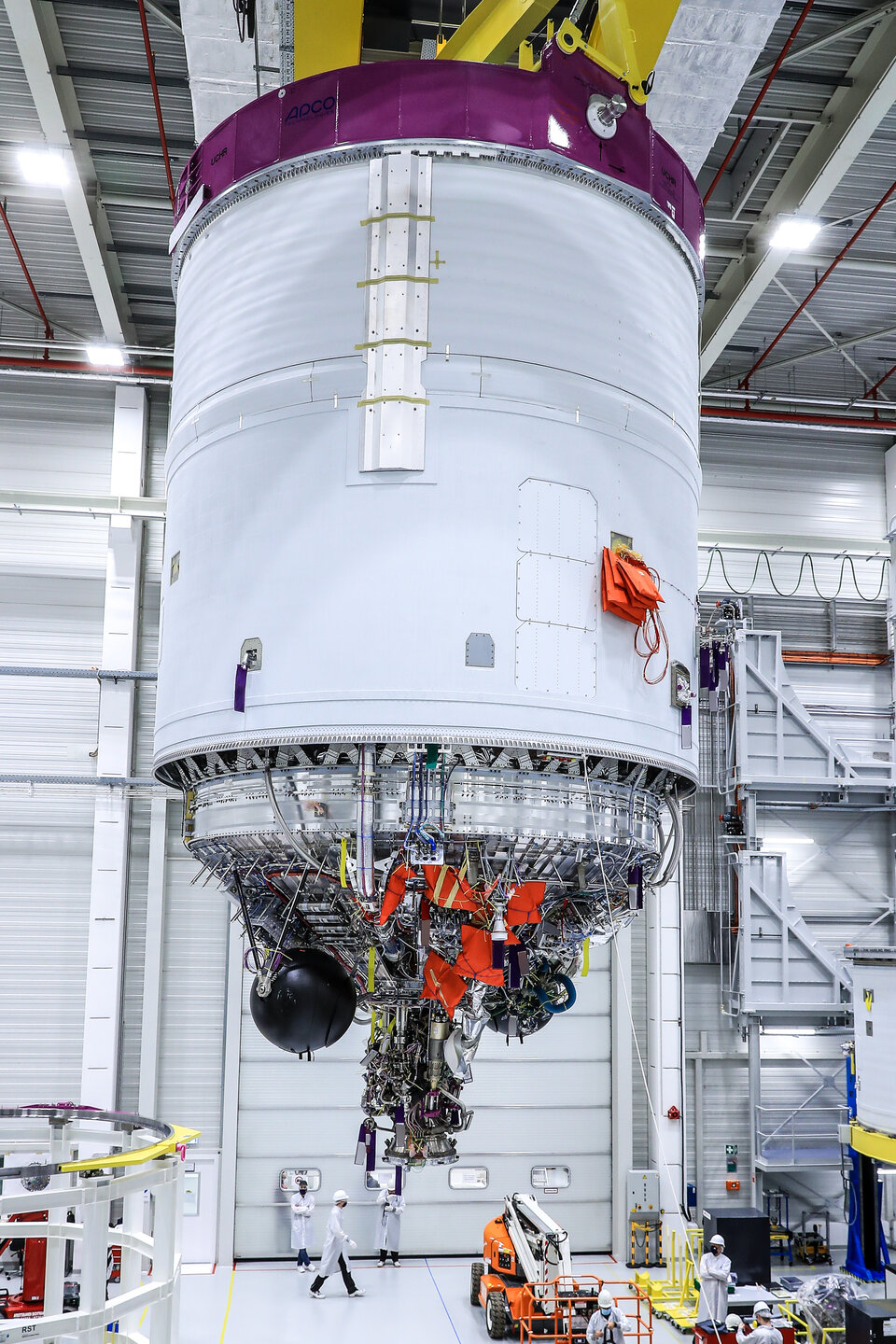

Main stage: upgraded to its core

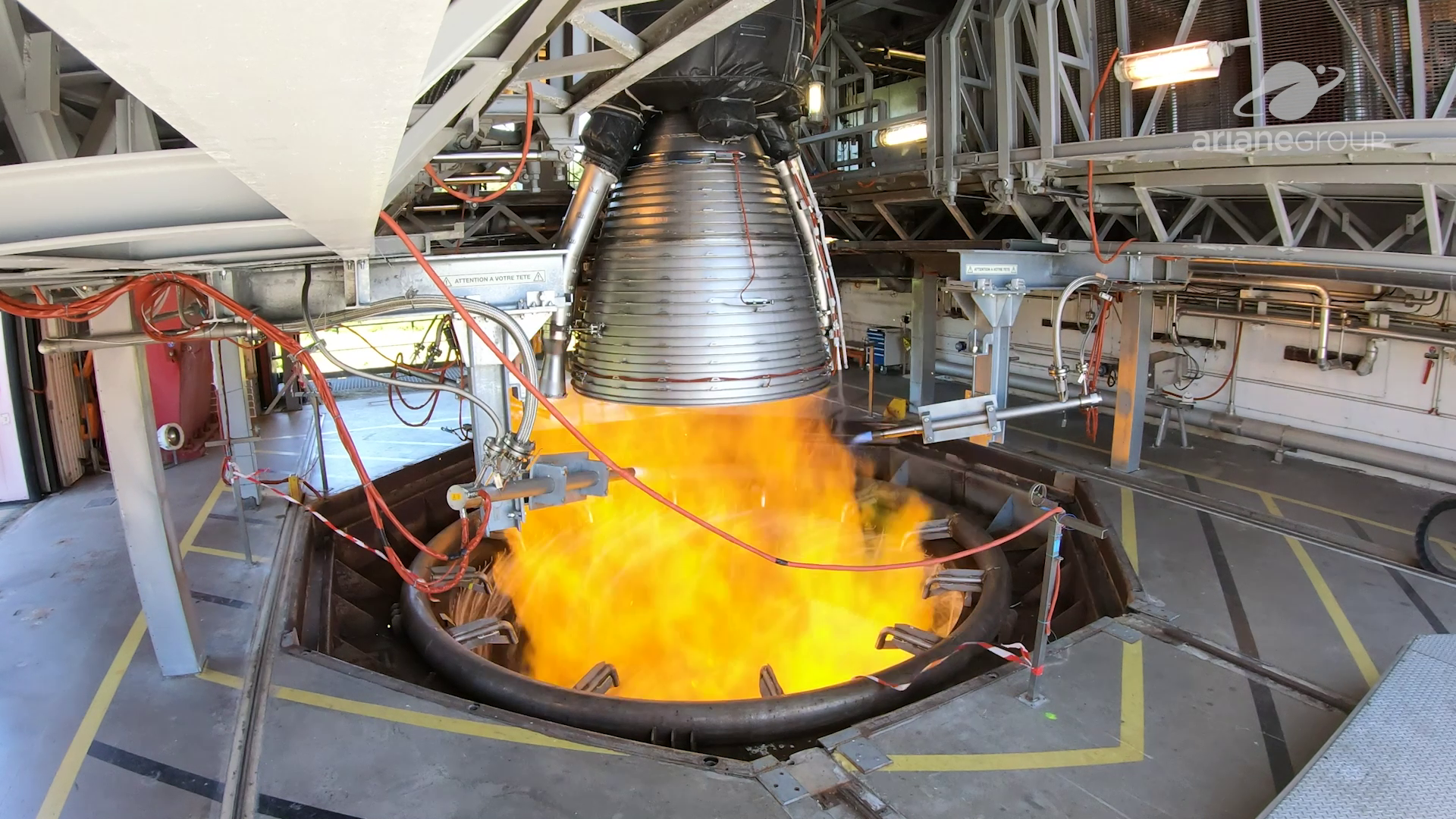

The main stage, also called the core stage, is the largest chunk of the Ariane 6 rocket and sits at its base. At 32 m tall, 5.4 m wide and weighing 23000kg without propellants, it is powered by the Vulcain 2.1 engine that burns liquid oxygen and hydrogen to generate 138 tonnes of thrust. The Vulcain 2.1 engine is an upgraded version of the Vulcain that powered the Ariane 5. Its nozzle is rapidly tilted and turned during a launch to keep the rocket flying upright, like balancing a pencil vertically on the end of your finger (while rushing through Earth’s atmosphere.) This Ariane 6 nozzle is even more robust than the one that came before it, built by laser-welding two large sheets of metal together and creating ‘cooling channels’ inside them.

Access the video

The main stage also includes the liquid propellant tanks that house the almost 154 tonnes of liquid hydrogen and oxygen fuel. Both must be cooled to incredibly low temperatures and put under high pressure to get them into liquid form, –182°C for oxygen and –253°C for hydrogen. These tanks need to be strong and well protected with insulating materials. Despite their strength, Ariane 6’s new cryogenic tanks are made with new welding techniques from a lighter mixture of aluminium and lithium material compared to the aluminium alloy parts used for Ariane 5 – another way mass has been reduced in the launcher.

A huge number of technologies, materials and teams have created a stronger, lighter, and lower-cost main stage for Ariane 6. It all comes together to propel the new rocket for the first 10 minutes of flight when Earth’s gravity is at its strongest, and up to an altitude of about 200 km.

Boosters: solid power in two or four

Added to the main stage of Ariane 6 are either two or four P120C solid rocket boosters, each 13.5 m long and 3.4 m in diameter. The motor that drives each of these powerful boosters is ESA’s new solid propulsion workhorse, filled with about 142 tonnes of solid propellant each providing about 4500 kN of maximum thrust. Working together, the boosters provide the majority of the thrust during a launch to get Ariane 6 off the launch pad.

The P120C also ‘doubles up’ as the first stage motor of the Vega-C rocket, burning for 130 seconds up to an altitude of about 70 km. Developing one motor for two such different rockets is a pivotal achievement of European industry, cutting costs and creating an opportunity for Europe to scale up production.

Access the video

Upper stage: restartable, flexible, responsible

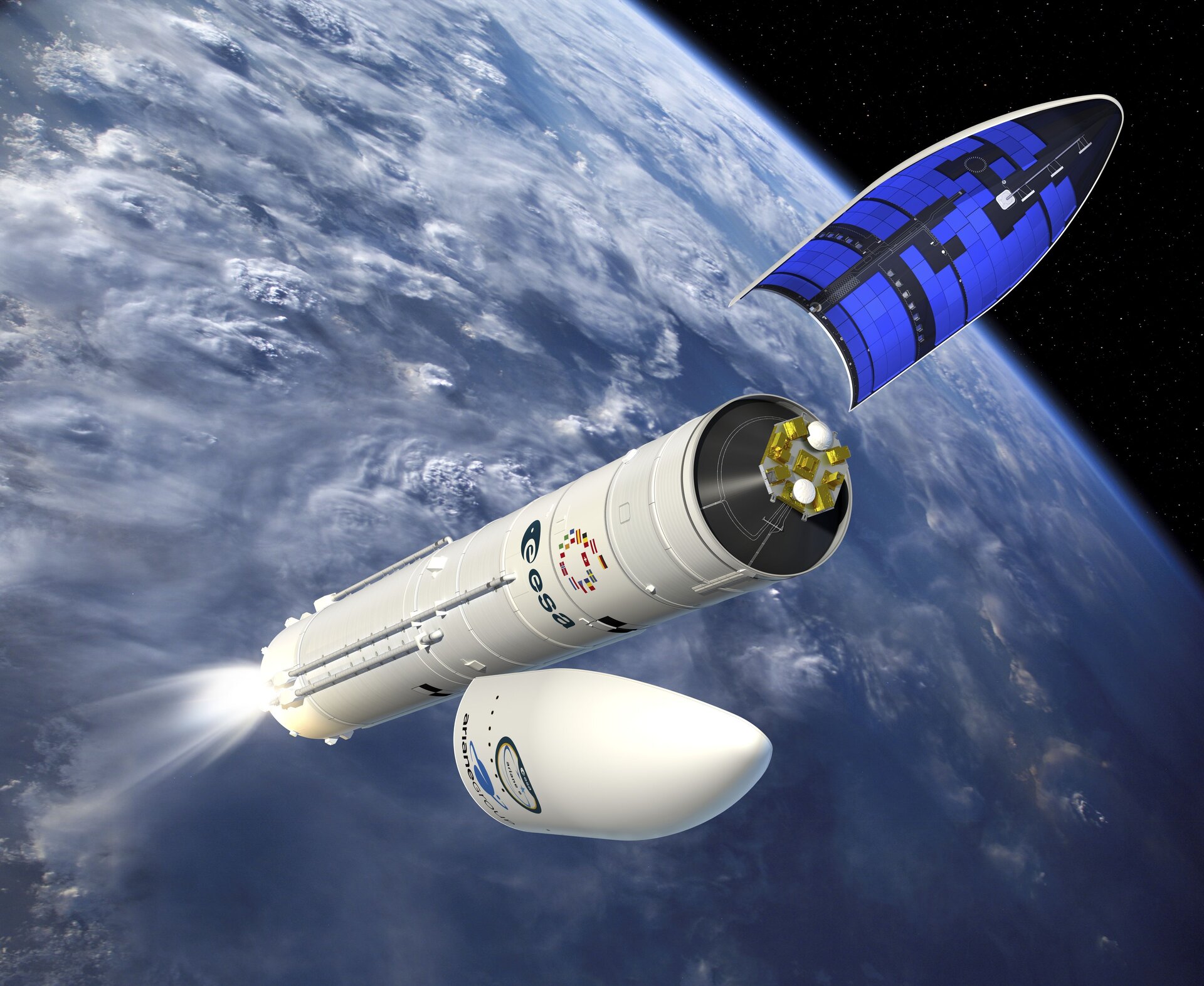

Once the main stage has done its job it separates from the upper stage and reenters Earth's atmosphere, to splash down in the ocean. The upper stage is now responsible for orbiting the payload, powered by the all-new restartable Vinci engine, fuelled by 30 tonnes of cryogenically cooled liquid oxygen and liquid hydrogen.

A crucial part of the upper stage is the Auxiliary Propulsion Unit (APU) – a small system that plays a vital role by pressurising the fuel tanks during flight and providing additional thrust on demand.

The upper stage will be able to fire up to four times, dropping off multiple passengers into different orbits on the same flight and then deorbiting itself through Earth’s atmosphere at the end of its mission, to ensure it does not become space debris.

Carbon fibre nose cone

It’s the part of the rocket that gets to space first, but to get there it has to ‘pierce’ through Earth’s atmosphere and withstand immense heat, acoustic and aerodynamic stresses. Ariane 6’s nose cone, technically called the fairing, is 5.4 m wide and fully adapted to carry the widest array of space missions. And it is flexible, available at both 14 m and 20 m tall it could carry four giraffes standing on each other’s shoulders.

The fairing consists of two huge half-shells, made in one piece from carbon-glass fibre composite which is ‘cured’ in an industrial oven, reducing cost and speeding up production. Fewer parts allow for horizontal as well as vertical assembly of the closed fairing and the launch vehicle, which is particularly important for Ariane 6.