Smart slit unit for the next generation of high resolution spectrometers

The push for higher performance in dispersive imaging spectrometers for remote sensing, combined with the availability of new technologies poses a challenge to improving on the current technology.

Today’s remote sensing instruments for imaging spectroscopy still face well known performance limitations and, in turn, product limitations. This is often due to scenes that show high contrast, such as clouds over a dark area, or sun glinting off of snow. This can mean stray light or oversaturated pixels.

Another challenge with state-of-the-art spectrometer designs is more noise on the spectral response, degrading the performance. The solution to both of these issues is to use a smart slit assembly with the ability to select or attenuate the scene transmitted to the spectrometer and to scramble the input for each pixel.

An activity with TDE and Micos Engineering in Switzerland has built a smart slit unit breadboard and verified it for use in a future Earth observation optical instrument.

The new instrument had to be able to handle performance issues such as stray-light and detector noise.

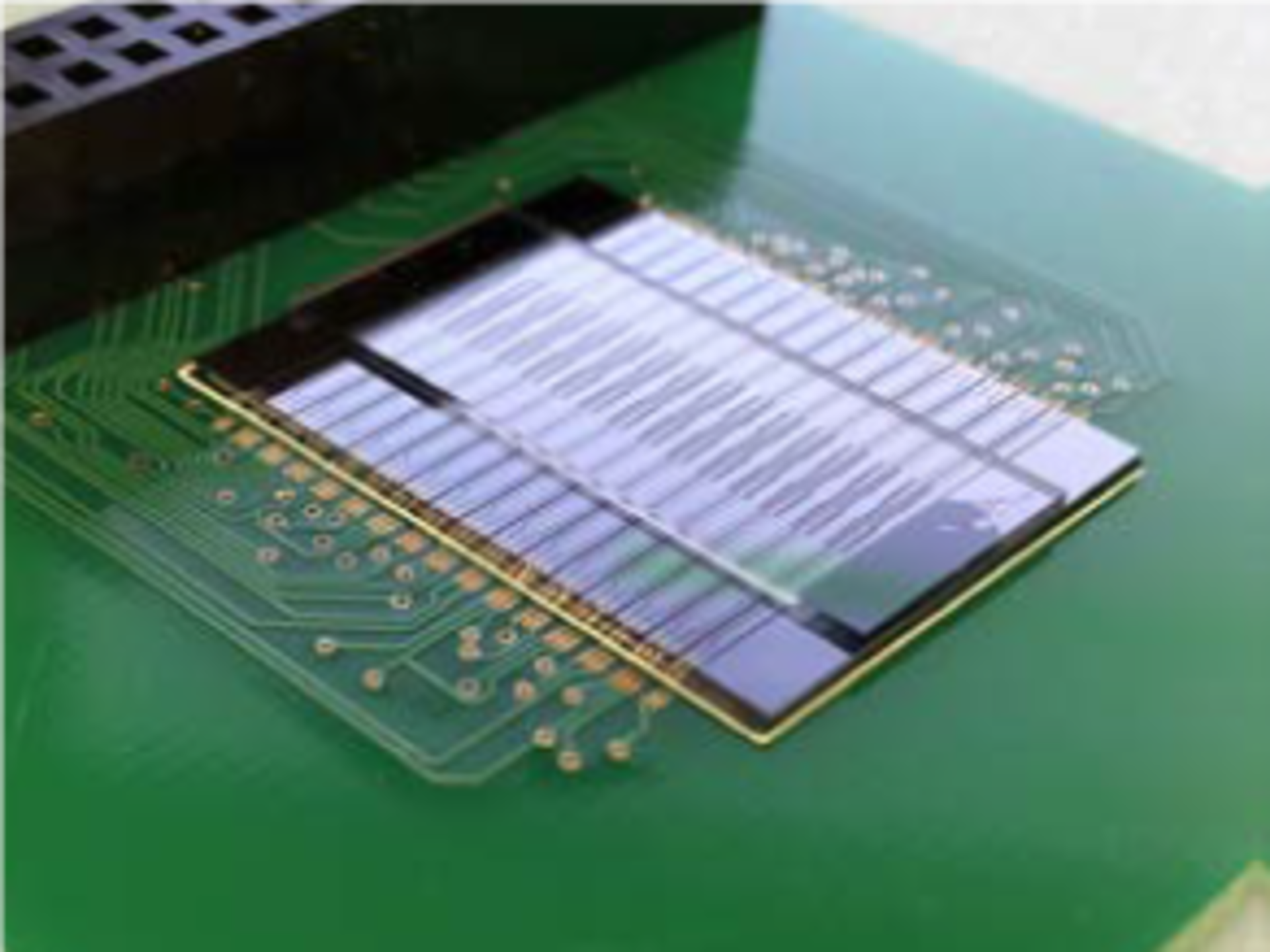

The unit encompassed the Smart Slit component, the driver electronics as well as the laptop with the software necessary to drive the system. It included the shutter and mirror array and additional optical components.

The activity showed that the issue of straylight could be reduced by a factor of 3 on a mission, such as Sentinel-5 with an improved assembly.

For instance, the new system could enable new science with images of heavily cloudy scenes, or Earth scenes in the middle of clouds. The activity could also make scene intensity modulation possible.

Future atmospheric science missions, imaging spectrometers, airborne and astronomy missions could benefit from such a component to improve their performance and generate new science and products.

T116-406MM closed in 2021.