New technology makes wind turbine blades environmentally friendly

An innovative GSTP activity (G627-082MS) has seen a new composites manufacturing technology developed by ÉireComposites, which enables the cost-effective production of robust thermoplastic wind turbine blades.

Traditional wind blade manufacturing processes emit high levels of Volatile Organic Compounds, so finding an environmentally more sustainable process for building them is vital. The new thermoplastic wind blades are fully recyclable, overcoming that particular environmental concern.

The spin-out activity, saw substantial mechanical testing of the potential materials for the blades carried out, to characterise the strength and stiffness performance of laminates produced by vacuum and positive pressure manufacturing processes. Around 340 materials were tested but the best performing in terms of strength, stiffness, hot/wet performance and availability resulted in the selection of a black fabric and a white UD tape. The team focused on the materials which had the best high cycle fatigue since the OGT wind turbine operates at a high RPM (350 RPM) and the blades pass the support beam twice per revolution, making this property more relevant to the blade design.

The team also developed a direct electrically heated mould that operates at temperatures above 200oC. The mould was key to making this new technology viable as it means the novel thermoplastic materials (the project used polypropylene reinforced by glass fibre) can be fully exploited.

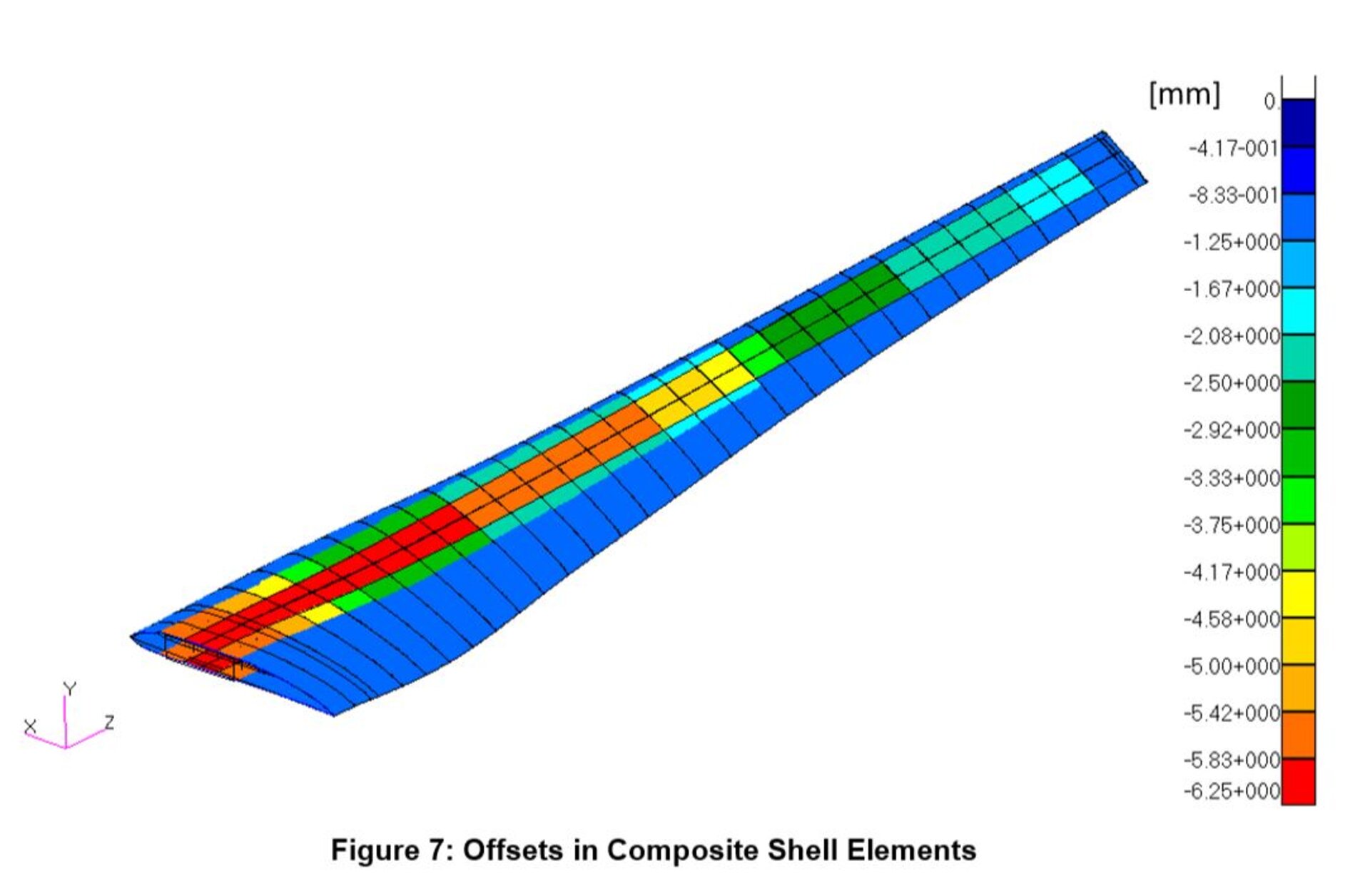

After this testing the blade’s internal structure was re-designed including modifications to the area around the root and an optimised layup and the original bonded root joint was replaced with a bolted joint. Once this was complete a full scale wind turbine blade was tested to demonstrate that it could withstand the ultimate loads to which it is expected to experience during its service life.

The blade met all safety and performance requirements.