Solar Orbiter’s shield takes Sun’s heat

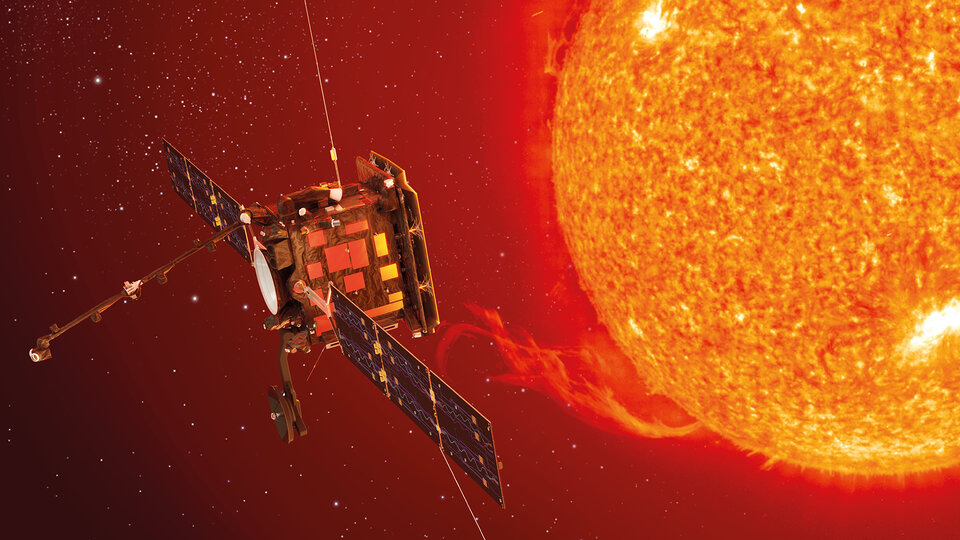

ESA’s Solar Orbiter mission has undergone its latest major test: its protective shield has been subjected to concentrated sunlight to prove it can cope with the fierce temperatures close in to our parent star.

A ‘structural–thermal’ version of the craft’s sunshield was recently exposed to an artificial Sun for two weeks in Europe’s largest vacuum chamber at ESA’s Technical Centre in Noordwijk, the Netherlands.

The outcome ensures it will balance solar illumination, the cold of deep space and internal heat sources to maintain the perfect operating temperature.

Solar Orbiter, due for launch in 2017, sports a portfolio of instruments for in-situ measurements and high-resolution imaging of the Sun.

The craft will probe to within almost a quarter of Earth’s distance from the Sun, suffering 13 times the intensity of terrestrial sunlight and temperatures of up to 520°C.

This means Solar Orbiter has been designed around its sunshield: a 3.1 m by 2.4 m sandwich of high-temperature multilayer insulation foil with a black-treated surface.

Openings allow sensors to peep through, some behind protective glass or beryllium.

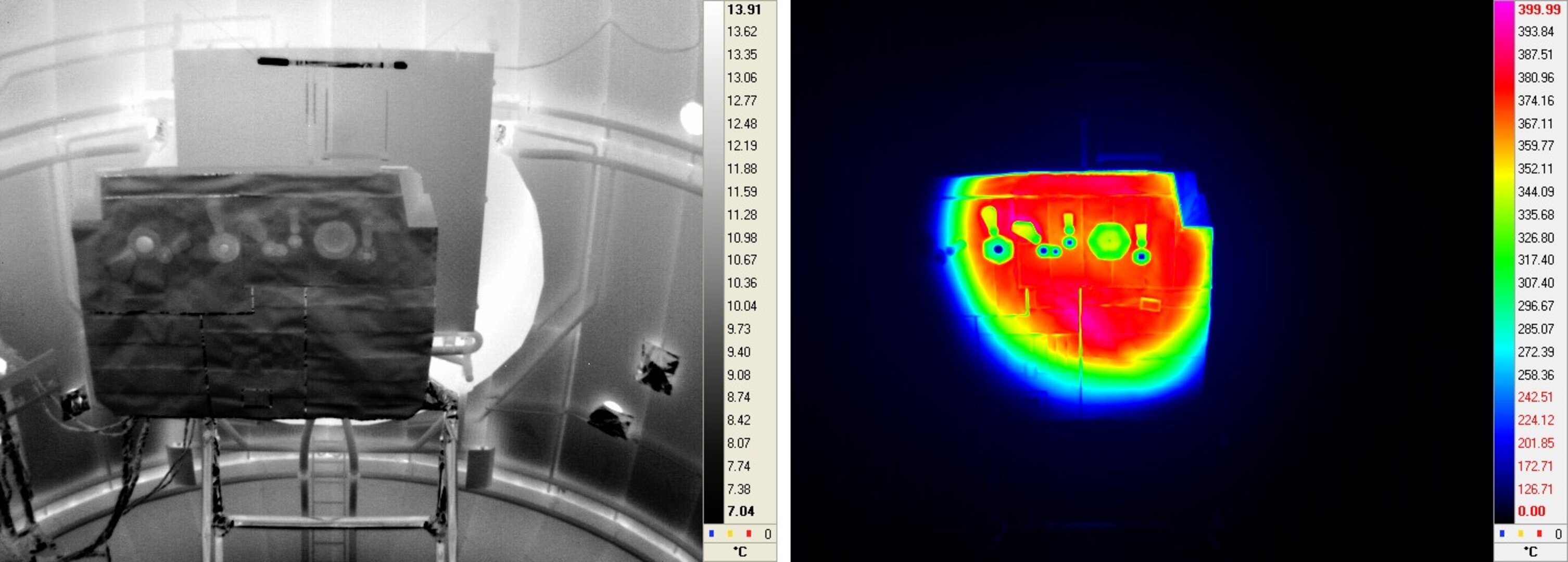

The sunshield was installed in the 15 m-high and 10 m-diameter Large Space Simulator in May for testing.

Part was blasted by a beam of simulated sunlight produced by 19 xenon lamps – each consuming 25 kW – and directed onto the shield via a mirror array.

Meanwhile, the chamber’s black walls were chilled by –170°C liquid nitrogen running through them to simulate the cold sky surrounding the craft.

The testing confirmed the design and checked the thermal computer model will accurately predict flight temperatures.

An infrared camera system monitored and measured the temperature of the shield’s front face in real time, along with heat sensors glued to various parts of the multilayer structure.

At the same time, precision ‘photogrammetric’ cameras looked for the slightest movement in the sunshield’s front face as it heated up.