Boosters (EAP)

The Ariane-5 solid propellant boosters are the largest solid rocket boosters ever produced in Europe.

Weighing 37 tonnes each when empty, they are 31 m high and 3 m in diameter. Each booster, or EAP as they are referred to from the French Etage d'Acceleration à Poudre, can contain about 238 tonnes of propellant. Ariane-5 boosters provide 1100 tonnes of thrust, roughly 92% of the total thrust at liftoff.

Each EAP consists of a steel casing enclosing three segments filled with propellant and joined together. The top segment is loaded with 23.5 tonnes of propellant in Colleferro (Italy), while the middle and bottom segments are filled in the solid propellant production plant (UPG) at the Spaceport. The middle segment contains 107.5 tonnes of propellant and the bottom segment contains 107 tonnes of propellant. Although the casings are only 8 mm thick, they can resist pressures of up to 64 bar.

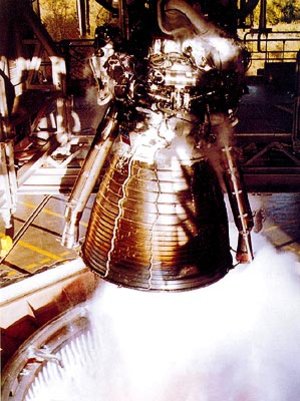

After arrival of the top segment from Italy, the boosters are assembled at the Spaceport and then anchored to the main cryogenic stage on the launch table. At the base of each booster is the 3.8 m long solid rocket engine nozzle. This can be swivelled up to 7.3° degrees around its axis by a nozzle-actuating unit to vary the direction of thrust. The outer diameter of the nozzle is 3.1 m.

Approximately 132 seconds after liftoff, at an altitude of 60 km, pyrotechnic devices free the boosters and separation rockets distance the spent boosters from the main stage. The boosters then continue their trajectory for about 100 km before falling into the Atlantic Ocean, approximately 450 km from the launch site. From time to time, when performance of the launcher allows it, the boosters are equipped with a parachute recovery system. After sea recovery, boosters are examined to check that the stage performed as expected.

It takes 350 milliseconds for the igniter in the upper segment of the booster to ignite the propellant. The radial rate of combustion, from the centre to the exterior of the booster segment, is approximately 7.5 mm/sec. Specific impulse is 262 sec., maximum pressure 64 bar and thrust 5400 kN. Gases from the combustion are expelled at an average flow rate of 2 tonnes/sec.

The propellant has three main constituents:

- ammonium perchlorate: the oxidiser

- aluminium powder: acts as the reducer

- polybutadiene: binder and catalyser

Responsible contractor: EADS/LV (France)

motor: EUROPROPULSION (France-Italy)

nozzle actuators and structures: SABCA (Belgium)

sea-recovery systems: Dutch Space the Netherlands)

The solid propellant production plant (UPG) at Europe’s Spaceport is operated by the French-Italian company REGULUS.