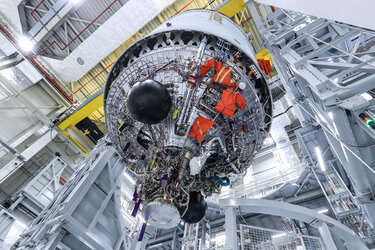

TEST-FUCHS valve

Thank you for liking

You have already liked this page, you can only like it once!

TEST-FUCHS valve.

TEST-FUCHS, based in Gross-Siegharts deliver high-precision valves and coils for electro valves for the lower and upper stage of Europe's rocket Ariane 6. While they deliver only electrical-actuated valves for flow regulation and specific coils for electromagnetic actuation in the core stage, the upper stage also contains passive non-return check valves.

These check valves are specifically developed and produced for the Vinci engine’s hydrogen Propellant Pressure Distribution and Regulation system (PPDRO/H) and the stage’s Auxiliary Power Unit. The check valve controls the flow of propellant and prevents ‘backflow’ – essential for maintaining stable pressure. As hydrogen is the smallest molecule in the universe, designing and building valves to stop and start the flow of hydrogen on command is no easy feat and requires immense precision and quality control. TEST-FUCHS engineering contributes to the precise fuel management required for a stable, safe and successful launch.

Austria’s contributions to Ariane 6 exemplify the country’s expertise in high-precision manufacturing and advanced engineering. Through the work of these companies and many more across Europe, Ariane 6 can safely survive the extreme temperature fluctuations any rocket encounters being fired from Earth to space, can be guided safely, flies with cutting-edge communication systems and safety features that help it achieve its missions with confidence and reliability.

-

CREDIT

TEST-FUCHS -

LICENCE

ESA Standard Licence

TEST-FUCHS valve

Ariane 6: made in Austria

Biomass cleared for fuelling

Ariane 6 complete upper stage