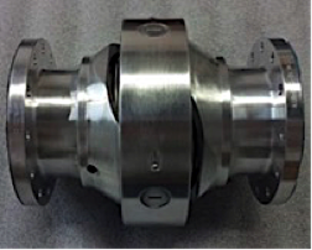

Friction stir welding machine at MT Aerospace

Thank you for liking

You have already liked this page, you can only like it once!

Once a metal part is made, it often needs to be joined to other components. In the space industry, friction stir-welding is replacing traditional arc welding done by humans or robots. Friction stir welding heats up the metals by simply rotating a pin over the welding area at high speeds, thereby using friction to stir the materials together. This precise welding technique fuses metals allowing for stronger structures, such as those used to make the tanks for Ariane 6.

With new digital monitoring technologies for weld force, temperatures and other machine telemetry, machine learning is now helping setup the machines faster, support documentation efforts and automatically check the shape of the final weld. This automatic evaluation of weld seams has reduced analysis time by 95% compared to the traditional process.

-

CREDIT

MT Aerospace -

LICENCE

ESA Standard Licence

Friction stir welding of titanium

X-ray test of friction-stir welded tank

Ariane 6 tank for the core stage

Extruded metallic inter stage structure