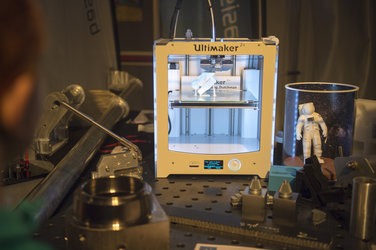

MELT 3D printer

Europe’s first 3D printer designed for use in weightlessness, printing aerospace-quality plastics, has won the prestigious Aerospace Applications Award from design-to-manufacturing specialist TCT Magazine.

ESA’s Manufacturing of Experimental Layer Technology (MELT) project printer has to be able to operate from any orientation – up, down or sideways – in order to serve in microgravity conditions aboard the International Space Station. Based on the ‘fuse filament fabrication’ process, it has been designed to fit within a standard ISS payload rack, and to meet the Station’s rigorous safety standards.

The MELT printer can print a wide variety of thermoplastics from ABS (Acrylonitrile butadiene styrene), as used in Lego, up to high-melting point engineering thermoplastics such PEEK (Polyether ether ketone), which is robust enough to substitute for metal materials in some cases.

“This printer could be used to make parts on demand for the repair and maintenance of a long-duration orbital habitat,” explains ESA materials and processes engineer Ugo Lafont. “This printer would also benefit human bases on planetary surfaces. Crucially, it can also print using recycled plastics, allowing a whole new maintenance strategy based on closed-loop reuse of materials.”

The printer was produced for ESA by a consortium led by Sonaca Space GmbH together with BeeVeryCreative, Active Space Techologies SA and OHB-System AG.

The MELT project was supported through ESA’s Technology Development Element programme, which identifies promising technologies for space, then demonstrates their workability.

Watch a video of the printer in operation here.