Where on Earth? Liège

Thank you for liking

You have already liked this page, you can only like it once!

Thousands of people in cities all over Europe are working to ensure European access to space, bringing all the benefits of our wider Universe to people on Earth. This satellite photo highlights one of the cities of Ariane 6, where people are working to make Europe’s new heavy-lift rocket, Ariane 6, fly.

Liège in Belgium is home to Safran Aero Boosters, who make propellant valves on the Ariane 6 launcher. Launching a rocket into space requires propellant, and lots of it. Ariane 6 hold 180 tonnes of propellant – liquid oxygen and liquid hydrogen – and just pumping it into the tanks takes about 3,5 hours. On the launch pad in French Guiana the control centre first begins by slowly cooling the pipes, valves, tanks and engines from the tropical temperatures of about 30°C down to the super-chilled temperatures of the cryogenic fuels.

As much an art as engineering, the propellants used by Europe’s new rocket Ariane 6 are supercooled to –180°C for the oxygen and –253°C for the hydrogen fuel. At these temperatures, any humidity already in the pipes would immediately freeze and could lead to blocked valves. To avoid this, any hint of air or moisture from the atmosphere was flushed out of the system by the inert (unreactive) gas, helium, before fuelling begins.

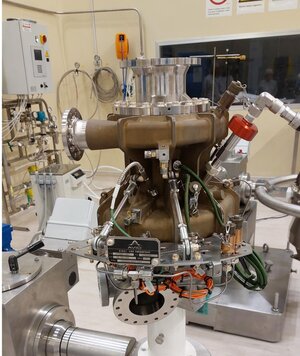

Once the rocket is ignited two turbopumps inject the hydrogen and oxygen into the combustion chamber. The burnt gases are then ejected at the nozzle outlet. The liquid hydrogen turbopump alone turns at 33 000 revolutions per minute and produces 15 megaWatts of power – more than a high-speed train engine, and there are two turbopumps on Ariane 6 to keep the rocket satisfied with fuel, burning through 327 kg a second for almost eight minutes as it ascends to space.

-

CREDIT

Contains modified Copernicus Sentinel data (2023), processed by ESA -

LICENCE

ESA Standard Licence

Avio liquid oxygen turbopump for Ariane 6 rocket mai…

Avio liquid oxygen turbopump for Ariane 6 rocket eng…

TEST-FUCHS valve

TEST-FUCHS valve