3D-printed space metal in CT scan

Thank you for liking

You have already liked this page, you can only like it once!

This February, the first-ever metal part 3D-printed in space landed on Earth. Produced in the European Space Agency’s Metal 3D Printer Technology Demonstrator on the International Space Station (ISS), it is now in the hands of ESA’s engineers at ESTEC, the agency’s technical centre in the Netherlands, who poke and prod it to understand how microgravity affected its printing process.

“We are comparing this metal part with an identically shaped one created here on Earth, using the same printer before it was shipped to the ISS,” explains Caterina Iantaffi, ESA’s materials engineer. “What we are looking for are differences attributable to different gravity levels.”

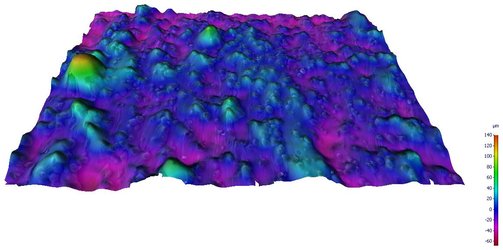

Caterina and her colleagues were able to take a peek inside the sample thanks to a CT scan, during which the metal sample rotated in a machine while being scanned using X-rays. This thorough examination resulted in a 3D digital model revealing the inside of the sample, allowing the researchers to identify the size and location of any pores (air bubbles).

[Image description: This is a photo of a laboratory workspace. A person wearing a blue lab coat with the logo of the European Space Agency on the back is facing with their back to the viewer. They are looking to their left side, through a window into a CT scan machine. Their right hand, wearing a blue glove, rests on a desk. There is a computer monitor, a keyboard and a mouse on the desk. On the monitor, there is a digital model of a sample that is being scanned inside the machine – consisting of a circular base and six cylindrical parts protruding from it.]

-

CREDIT

ESA-SJM Photography -

LICENCE

ESA Standard Licence

3D-printed space metal ready for tensile testing

3D-printed space metal ready for tensile testing

3D-printed space metal under microscope

3D-printed space metal under microscope