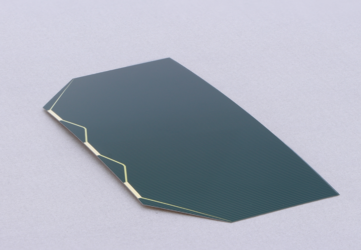

Sustainable thin-film space solar cells

Thank you for liking

You have already liked this page, you can only like it once!

For more than 30 years, III-V solar cells have become the standard power source for satellites thanks to their high efficiency and strong radiation tolerance compared with silicon-based solar cells.

These devices are fabricated by growing very thin semiconductor layers on germanium substrates using a process called epitaxy. After the layers are grown, the cells are manufactured using specific processes. This precise manufacturing approach is compatible with the harsh conditions in space, but it is resource and energy intensive, which clashes with Green Space sustainability goals.

A team from Fraunhofer ISE is developing an innovative mask-and-plate approach to microfabricate III-V space solar cells without the use of photolithography or metal evaporation, a solution supported by the European Space Agency through its Discovery & Preparation element. The idea was submitted via ESA's Open Discovery Ideas Channel (OSIP).

Find out more here.

-

CREDIT

Fraunhofer -

LICENCE

ESA Standard Licence

Bendy, ultra-thin solar cell

Solar cell system

Luxtelligence chips offer terabytes per second data…

30% efficiency solar cell