Geometric deep learning for the analysis and design of novel lattice structures

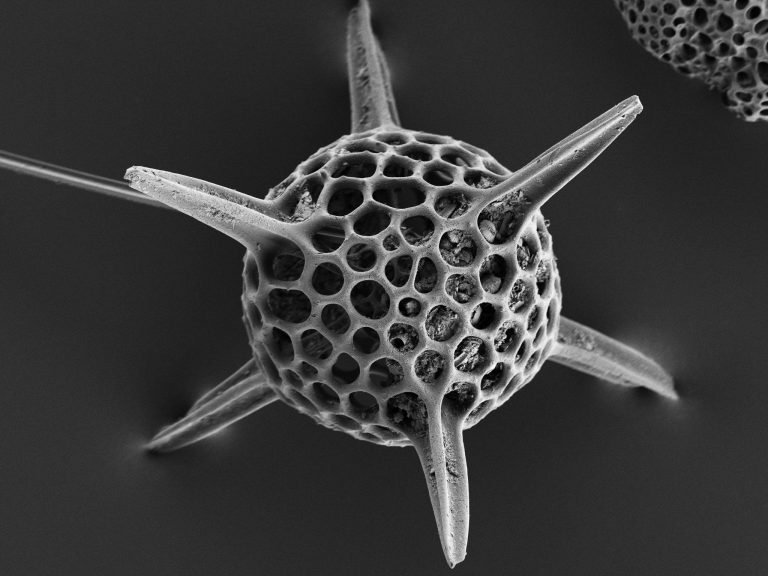

Materials used to build future space infrastructure, especially those built directly on other celestial bodies, will require demanding, environment-specific material properties while being relatively easy to process and shape [1]. Such constraints limit the palette of material composition that engineers can exploit to meet desired performance. Much like in nature, engineers will come to rely on the optimisation of a material’s topology and geometry in addition to its chemical makeup in order to achieve the desired properties. Bone, plant stems, dragonfly wings, coral, and radiolarians (Fig. 1) are just some examples of natural lattice materials that showcase how intricate architecture is used to achieve extreme mechanical performance with a limited choice of constituents [2]. Enhancements in e.g. strength, stiffness, impact toughness, fluid transport, and thermal insulation are all found while conserving light weight. Moreover, an understanding of topological features often unlocks deformation modes and damage tolerant mechanisms not achieved by the bulk material alone.

Inspired by this, synthetic lattice materials comprise a highly active area of research in materials science, owed to the emergence of modern digital design and fabrication tools. At ESA, capabilities for 3D printing lattices from a variety of space-relevant polymers and metals have been growing over the past decade [3,4]. The geometric freedom afforded by this technology, however, also creates an overwhelming design space of possible geometric features inspired by nature. This design space cannot be explored by engineering intuition alone.

Contrary to periodic lattice materials used for lightweighting (such as hexagonal honeycombs), irregular lattice patterns found in nature have been shown to boast extraordinary damage tolerance [5] and other surprising properties. Control over the most ‘beneficial’ features of these irregular tilings cannot be exerted analytically, and as such, we propose a numerical approach to characterise emergent properties in the ever-growing design space. To better understand such irregular structures and support the design of lattices with irregular and unintuitive connectivity, we investigate several approaches from machine and deep learning - with a special focus on graph neural networks (or message passing neural networks) that can be directly applied to a lattice's topology.

Project overview

Graph neural networks [6,7] have recently shown promising results in simulating material behaviour, such as for the molecular modelling of glass microstructure [8] and predicting mechanical properties from periodic 3D lattice geometries [9]. Here, we aim to extend such work to analyse the properties of any regular or irregular 2D lattice material, paving the way towards novel methodologies which can support material scientists in the design process for functional non-intuitive materials.

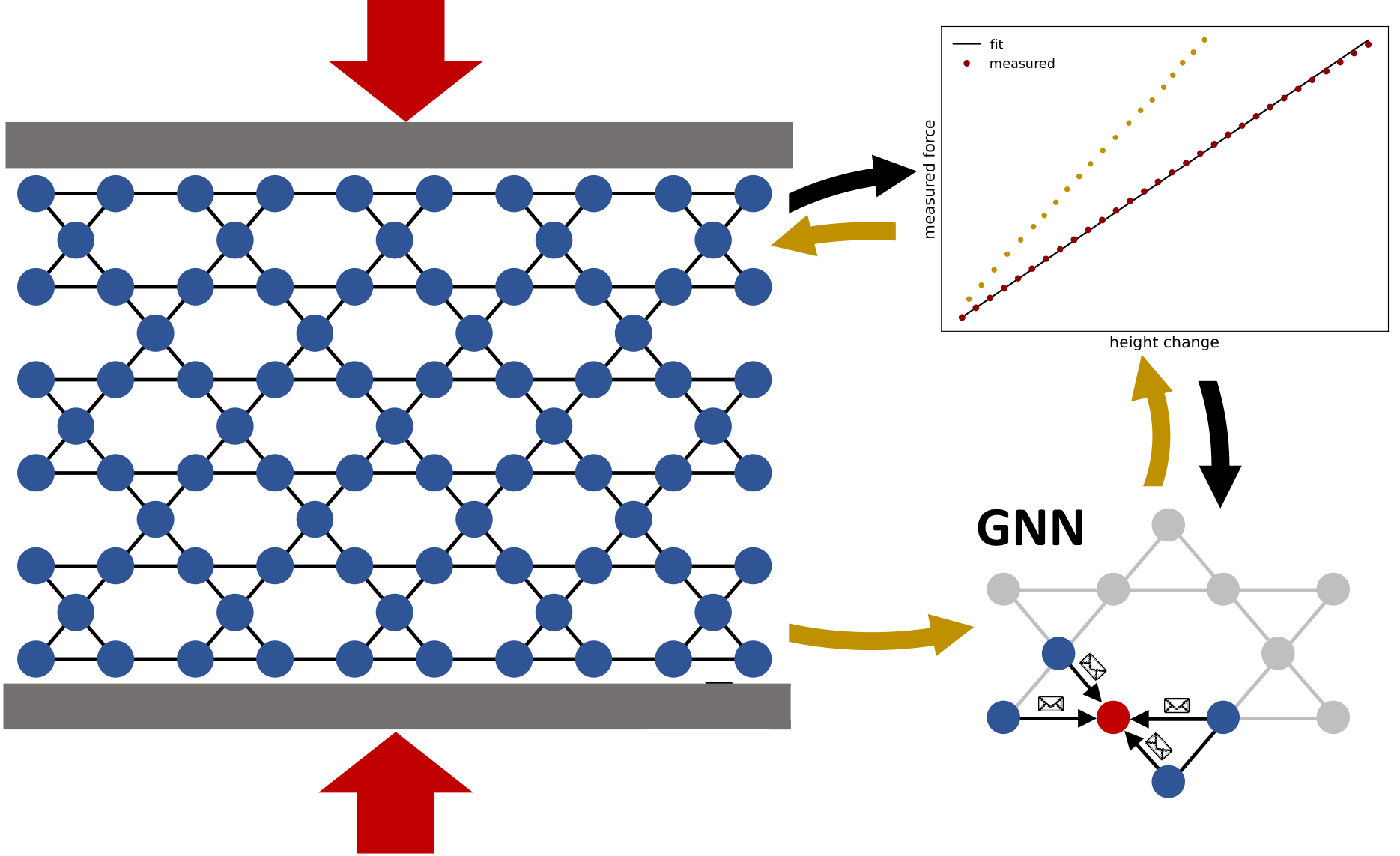

This project consists of two major parts: (i) evaluating the feasibility of graph neural networks for property prediction from 2D lattice geometries and (ii) investigating the usability of explainable methods to analyse or even optimise the underlying lattice structure via an inverse design approach (Fig. 2). To get a proper understanding of the employed methods and the problem case, we are also looking into alternative models like standard neural networks.

References

[1] Ghidini, T. (2018). Materials for space exploration and settlement. Nature materials, 17(10), 846-850.

[2] Wegst, U. G., Bai, H., Saiz, E., Tomsia, A. P., & Ritchie, R. O. (2015). Bioinspired structural materials. Nature materials, 14(1), 23-36.

[3] Makaya, A., Pambaguian, L., Ghidini, T., Rohr, T., Lafont, U., & Meurisse, A. (2022). Towards out of earth manufacturing: overview of the ESA materials and processes activities on manufacturing in space. CEAS Space Journal, 1-7.

[4] Mitchell, A., Lafont, U., Hołyńska, M., & Semprimoschnig, C. J. A. M. (2018). Additive manufacturing—A review of 4D printing and future applications. Additive Manufacturing, 24, 606-626.

[5] Aranguren van Egmond, D. A. (2018). Designing for Disorder: The Mechanical Behaviour of Bioinspired, Stochastic Honeycomb Materials. Master's Thesis. University of Toronto.

[6] Kipf, T. N., & Welling, M. (2017). Semi-supervised classification with graph convolutional networks. 5th International Conference on Learning Representations (ICLR-17).

[7] Hamilton, W., Ying, Z., & Leskovec, J. (2017). Inductive representation learning on large graphs. Advances in neural information processing systems, 30.

[8] Bapst, V., Keck, T., Grabska-Barwińska, A., Donner, C., Cubuk, E. D., Schoenholz, S. S., ... & Kohli, P. (2020). Unveiling the predictive power of static structure in glassy systems. Nature Physics, 16(4), 448-454.

[9] Ross, E. & Hambleton, D. (2020). Using Graph Neural Networks to Approximate Mechanical Response on 3D Lattice Structures. Proceedings of Advances in Architectural Geometry, Paris 2020.