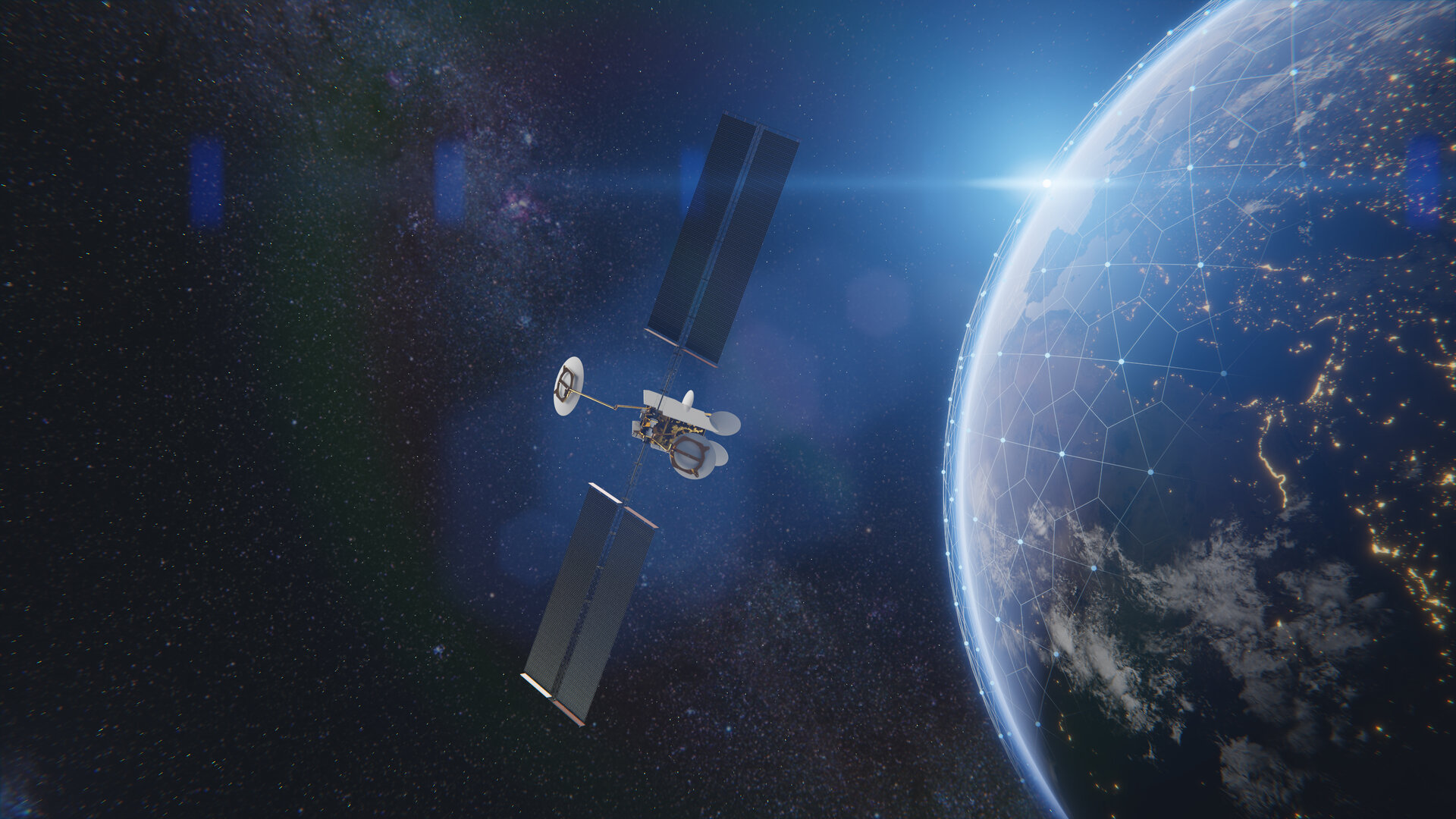

Software-defined OneSat ready for production

The latest type of telecommunication satellite that can respond from space to changing demands on Earth is about to start assembly of its electronic components.

The highly flexible satellite is setting a new paradigm for geostationary telecommunication satellites, by using off-the-shelf commercial components in the standardised physical hardware and using just software to configure bespoke missions.

Called “OneSat”, the design was developed in an ESA Novacom Partnership Project with satellite manufacturer Airbus, which has now sold seven different OneSats to various commercial customers. The satellites will be used to revolutionise in-flight connectivity for passengers on board planes, as well as to bridge the digital divide by connecting communities in remote areas.

OneSat is designed to meet the highest standards of availability and performance, while cutting equipment costs and assembly efforts. The design of the satellites’ electronics systems shows how these seemingly conflicting objectives can be met simultaneously.

OneSat’s avionics rely on two complex electronic units: the command and data management unit; and the power-supply regulator.

The command and data management unit, which is being designed and built by Airbus in Elancourt, France, monitors and controls everything on the satellite and continuously processes the data needed to operate it autonomously and safely.

The power-supply regulator, which is being developed and manufactured by Airbus Crisa in Tres Cantos, Spain, provides the electrical power needed for all equipment to fully function. It does this both during full daylight and eclipses, shifting power generation between solar arrays and batteries and ensuring a proper supply is available whether the satellite operates at full power or any fraction of its capacity.

These two vital equipment units must operate in a difficult environment for electronics, with high radiation levels and extreme temperature fluctuations.

To keep costs low and lead times short, these two units are being made from carefully selected commercial off-the-shelf components, rather than radiation-hardened ones specially developed for use in space.

This means the OneSat satellites will be able to use advanced technologies such as gallium nitride transistors on the power-supply regulator, which enables better performances and limits heat dissipation, compared with classical space-rated components.

Both equipment units passed their critical design review earlier this year and production of the flight models has now begun.

Through the OneSat Partnership Project, ESA helps Airbus and its European partners to shape the future of geostationary satellites, in collaboration with the French Space Agency (CNES), the Spanish Centre for the Development of Industrial Technology (CDTI) and the UK Space Agency (UKSA).

ESA Partnership Projects efficiently mitigate the risk borne by the European and Canadian space industry when developing ambitious endeavours.